Assembled valve

A combined valve and valve core technology, applied in the field of combined valves, can solve the problems of increased operating load, weak contact pressure of the sealing surface, and large-scale valve body of the driving part, and achieves the effect of improving the accuracy of flow control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

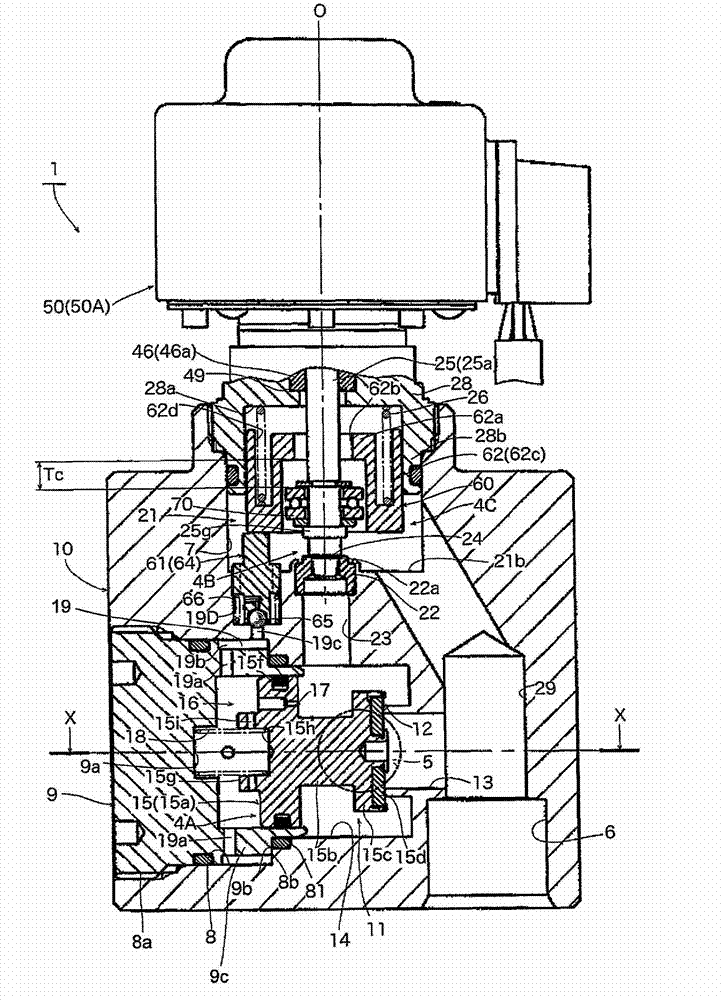

[0109] Embodiments of the present invention will be described below with reference to the drawings.

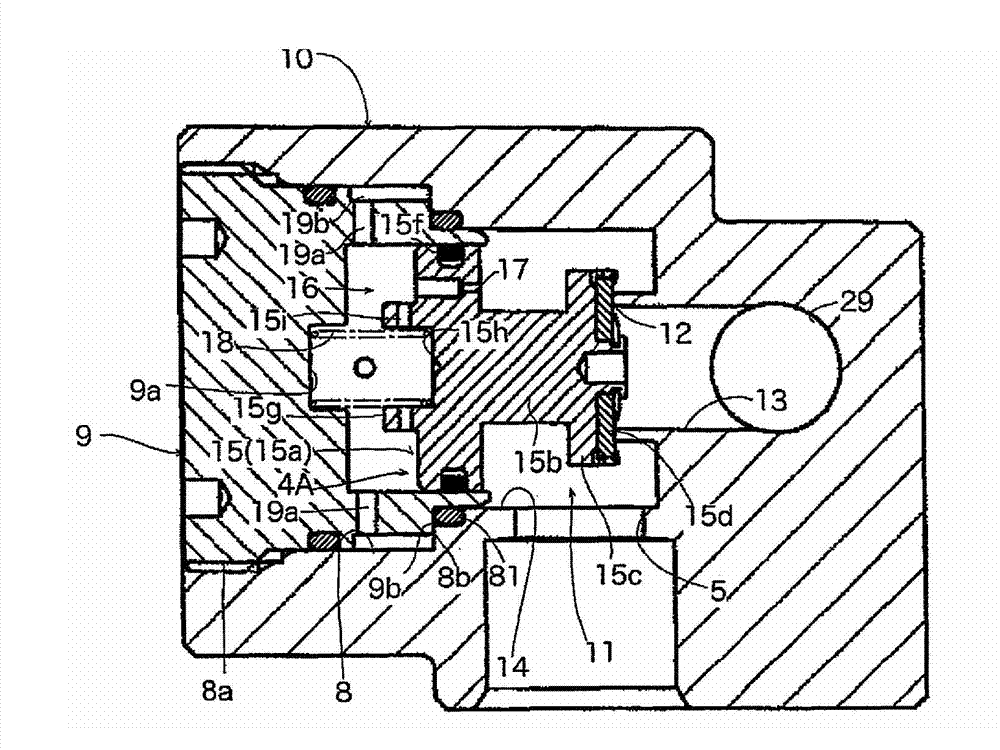

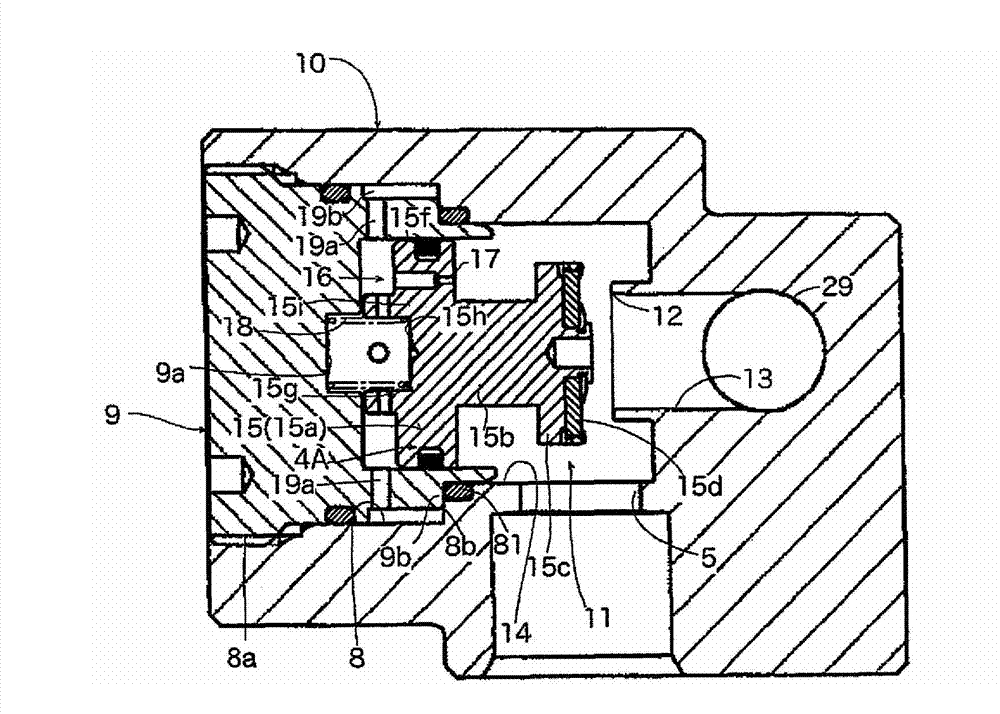

[0110] figure 1 , Figure 5 , Figure 7 It is a partial longitudinal sectional view showing an embodiment of the combination valve of the present invention, and each figure shows a different operating state. In addition, Figure 2(A) is figure 1 (the first control valve for large flow rate is in the closed state), the sectional view in the direction of arrow X-X, Fig. 2(B) is Figure 7 The sectional view in the direction of the Y-Y arrow (the first control valve for the large flow rate is in the open state). The internal structure of the stepper motor 50 part of the combination valve 1 of illustrated embodiment and Figure 11 The electric valve 1' of the prior art shown has the same structure, so only the outer shape of this part is shown. In addition, in each figure, the same as that shown in Figure 9 to Figure 11 The same symbols denote the same or equivalent parts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com