Control valve core device for high-precision automatic flow balancing valve and producing method thereof

A technology of flow control valve and flow balance valve, which is applied in the direction of valve device, balance valve, safety valve, etc., and can solve the problem of poor adaptability of control spool orifice and working pressure difference control range of automatic flow balance valve. , low flow control accuracy and other issues, to achieve the effect of convenient CNC machining, low manufacturing cost and high flow control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

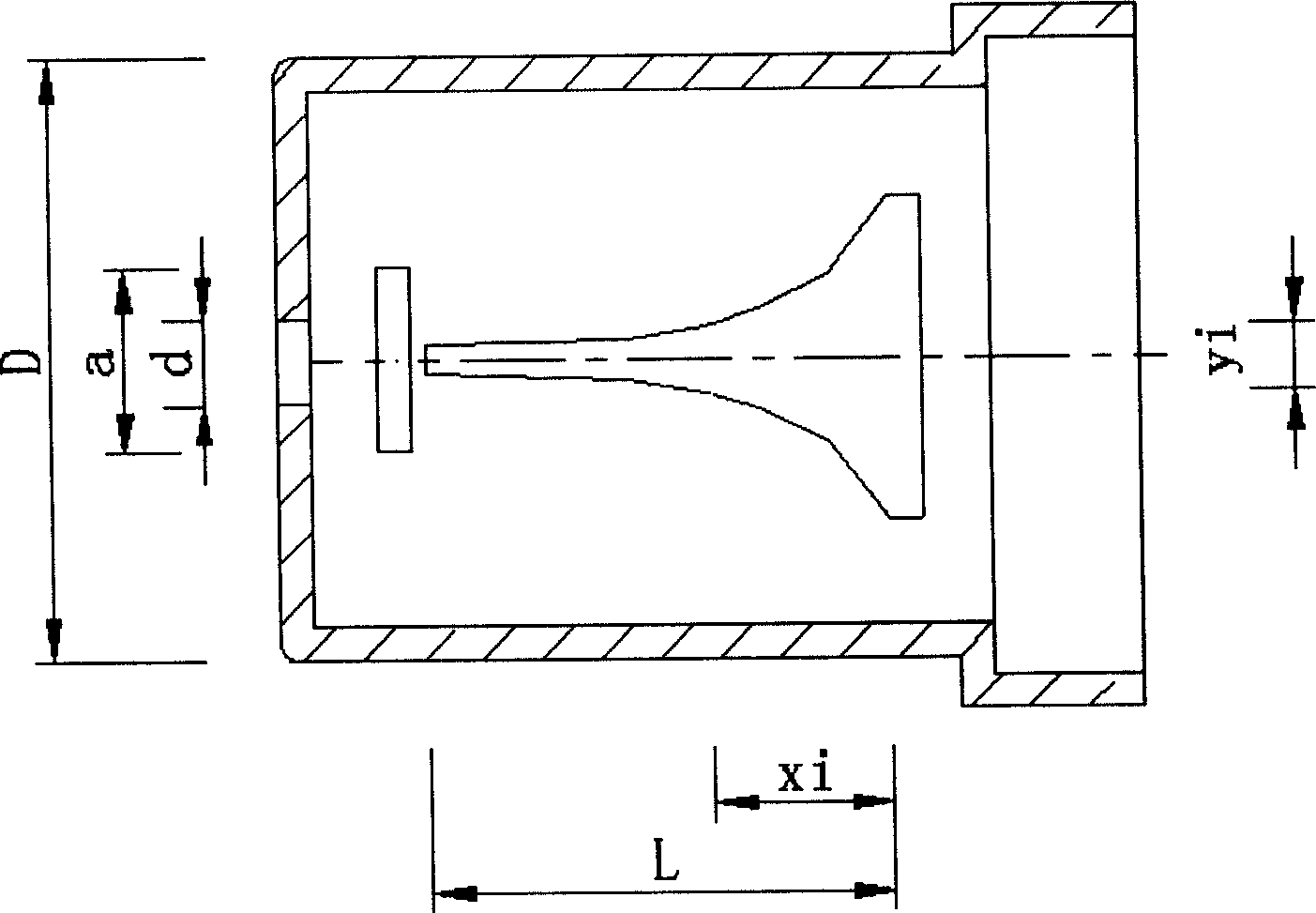

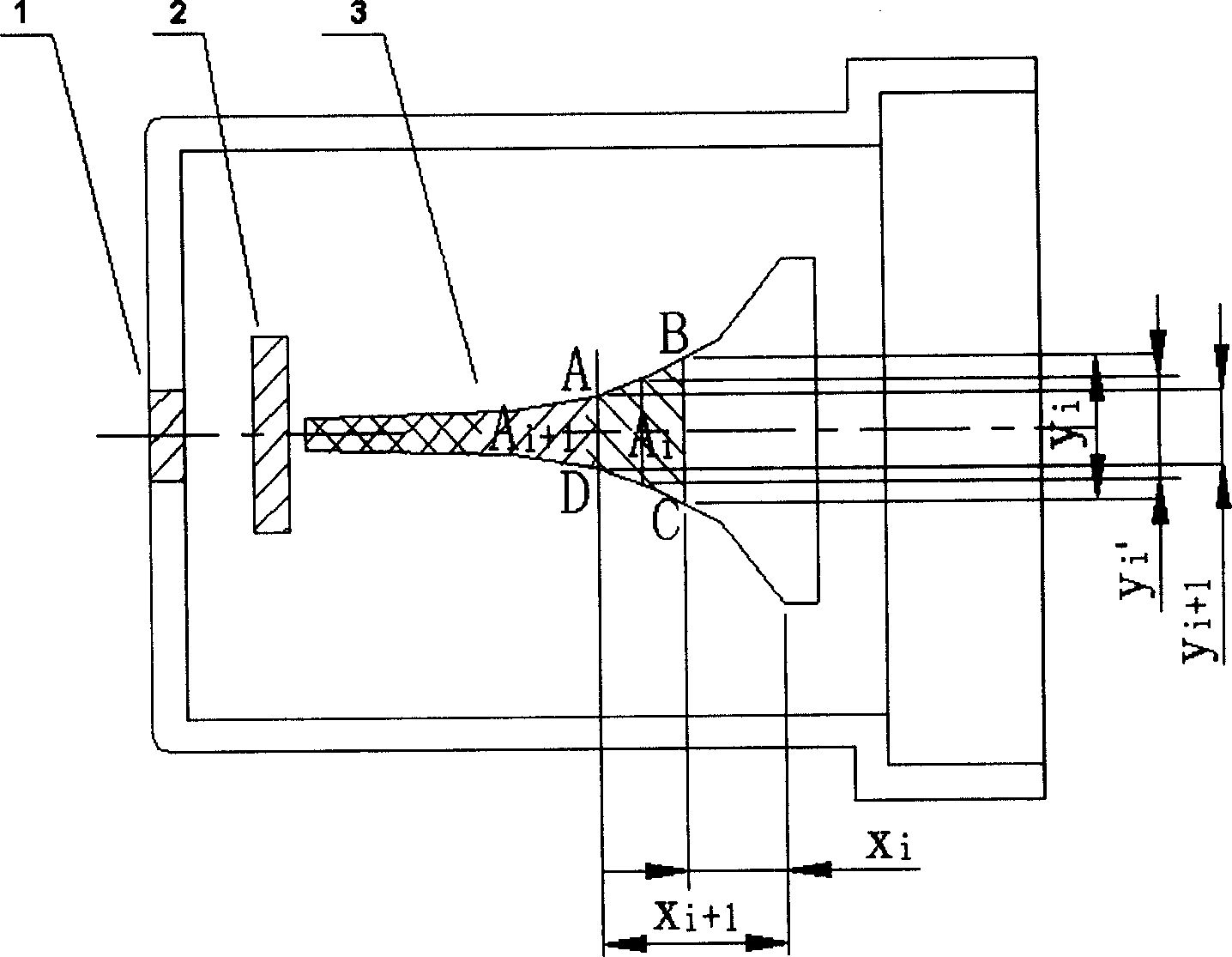

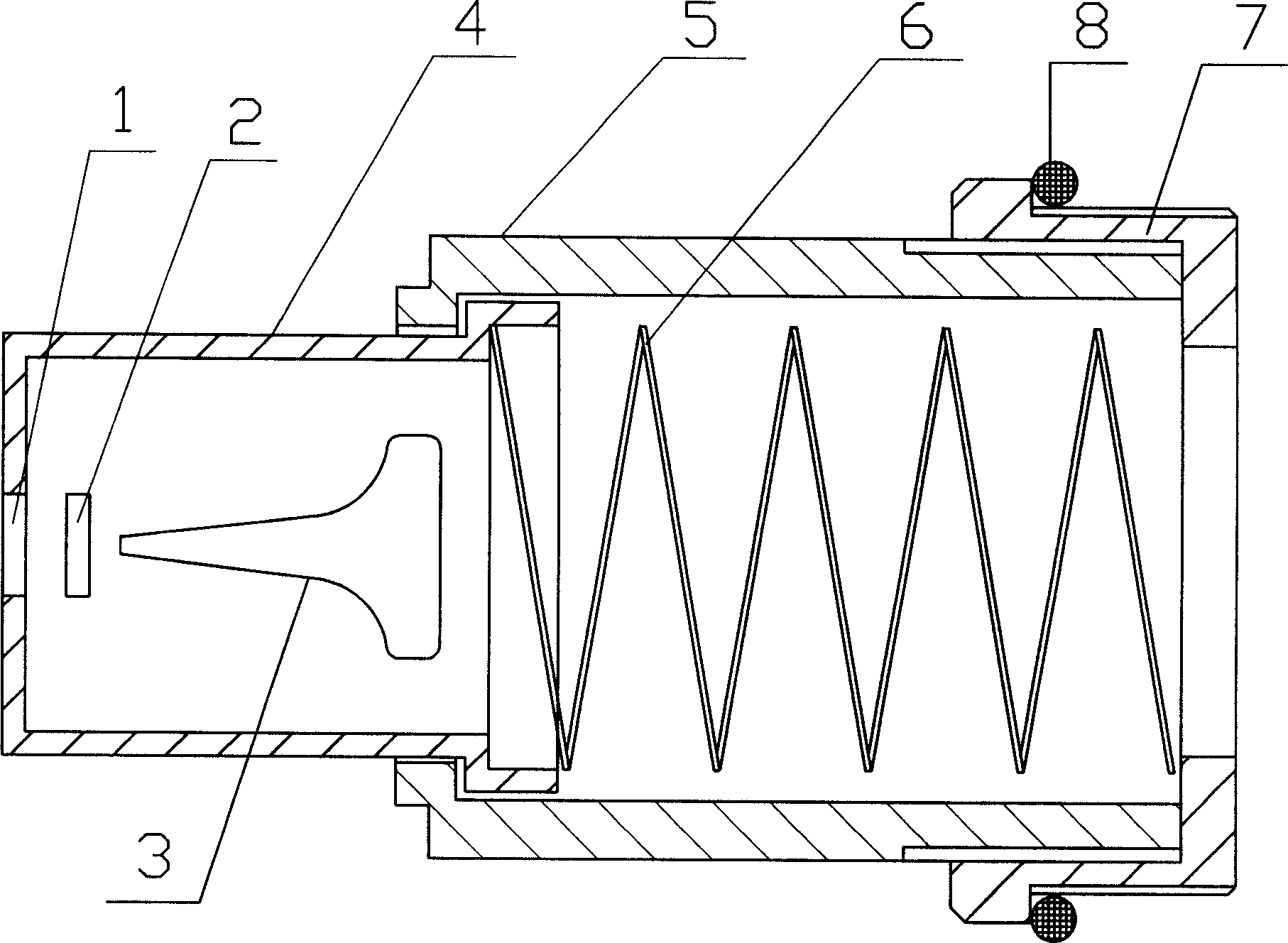

[0035] With reference to the drawings, the present invention will be described in detail below.

[0036] The control valve core device of a high-precision automatic flow balance valve in this embodiment includes a flow control valve barrel 5, in which a flow control valve core 4 and a linear coil spring 6 are sequentially installed, and the flow control valve barrel 5 The tail end is connected with the compression cover 7; the flow control valve core 4 is hollow and can slide along the inner wall of the flow control valve barrel 5. It is provided with an inlet end surface fixing hole 1 and an inlet side flow fixing hole 2 for flow control The wall of the valve core 4 also has two side flow channels 3 with arc-shaped edges gradually enlarged along the fluid flow direction. There is an O-ring 8 on the outer edge of the tight cover 7, and the end of the flow control valve barrel 5 and the compression cover Between 7 is a threaded connection, a compression connection or a snap-fit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com