Pilot type proportional flow valve and control method

A technology of proportional flow valve and pilot valve, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, threaded fasteners, etc. It can solve the problem of large pressure loss, low flow control accuracy and complex structure of proportional flow valve To achieve the effect of increasing the scope of traffic control and promoting intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

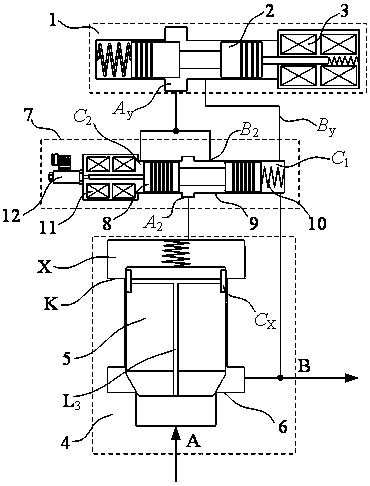

[0049] Such as figure 1 As shown, a pilot-operated proportional flow valve includes a proportional pilot valve 1 and a main valve 4 . Pilot proportional valve 1 includes pilot valve spool 2, pilot valve proportional solenoid 3, pilot valve oil inlet A y and pilot valve outlet B y ;The main valve 4 includes the main valve spool 5, the main valve sleeve 6, the main valve oil inlet A, the main valve oil outlet B and the main valve control chamber X; the main valve oil inlet A passes through the third flow of the main valve 4 Road L 3 Connected throttle groove C x , throttle groove C x The throttling edge K of the main valve sleeve 6 communicates with the control chamber X of the main valve 4 .

[0050] At the same time, between the main valve 4 and the pilot proportional valve 1, an active control type differential pressure compensator 7 is added. Main valve control chamber X and compensator oil inlet A 2 Connected, compensator oil outlet B 2 Simultaneously with pilot val...

Embodiment 2

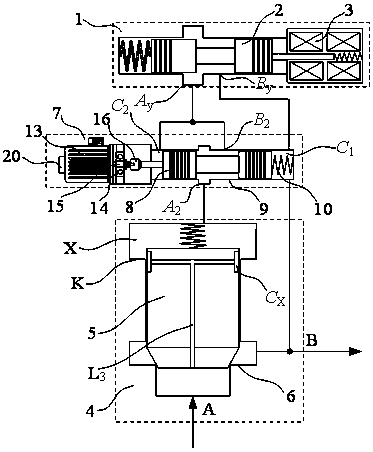

[0054] Such as image 3 As shown, the second embodiment of a novel pilot-operated proportional flow valve and its control method of the present invention is the same as the first embodiment in terms of structural composition and connection relationship, and the difference is:

[0055] Active control differential pressure compensator 7 is controlled by rotating motor 13 to drive ball screw 15, including compensator spool 8, compensator valve body 9, compensator spring 10, rotating motor 13, bearing 14, ball screw 15, push Rod 16, encoder 20, compensator oil inlet A 2 , Compensator oil outlet B 2 , Compensator spring chamber C 1 and compensator without spring chamber C 2 The compensator spool 8 is arranged in the compensator valve body 9, one end of the compensator spring 10 acts on one end face of the compensator spool 8, the other end acts on the compensator valve body 9, and is connected with the compensator spool 8 form the compensator spring chamber C 1 , the rotating ...

Embodiment 3

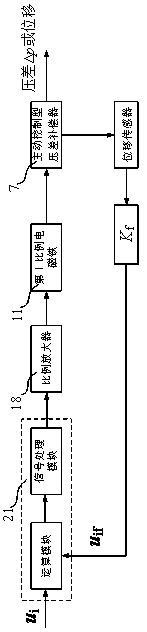

[0058] Such as Figure 5 As shown, the third embodiment of a novel pilot-operated proportional flow valve and its control method of the present invention is the same as the first embodiment in terms of structural composition and connection relationship, the difference is that the main valve 4 is provided with a second displacement sensor 17 ; The second displacement sensor 17 is connected with the main valve spool 5 to detect the displacement of the main valve spool 5 in real time.

[0059] Such as Image 6 As shown, when the active control type differential pressure compensator 7 controls the differential pressure, the steps are the same as in the first embodiment, and a nonlinear compensation algorithm is further added. The nonlinear compensation algorithm is: according to the formula In the formula, the opening area A of the proportional pilot valve is related to the displacement of the pilot valve spool 2. There are different calculation methods according to the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com