An electronically controlled compensation two-way proportional flow valve

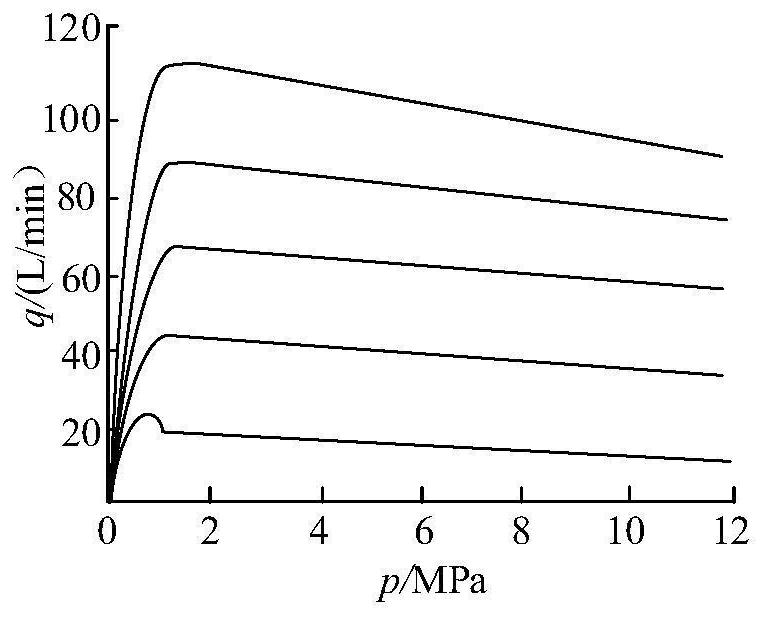

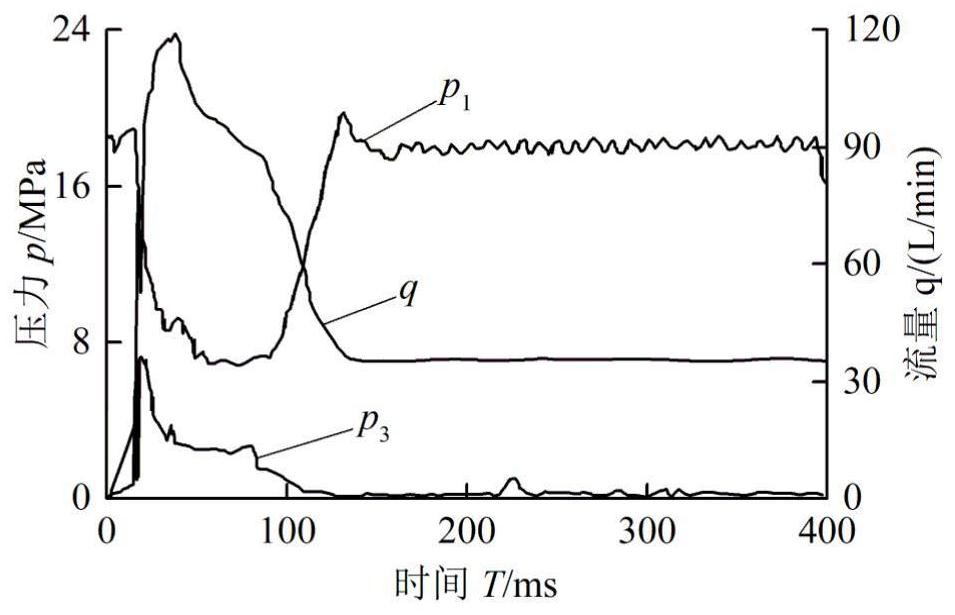

A proportional flow valve and compensation valve technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve problems such as control valves that are not suitable for large flow, complex structures, etc., to improve flow control accuracy, overcome The effect of poor controllability and good steady-state load characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

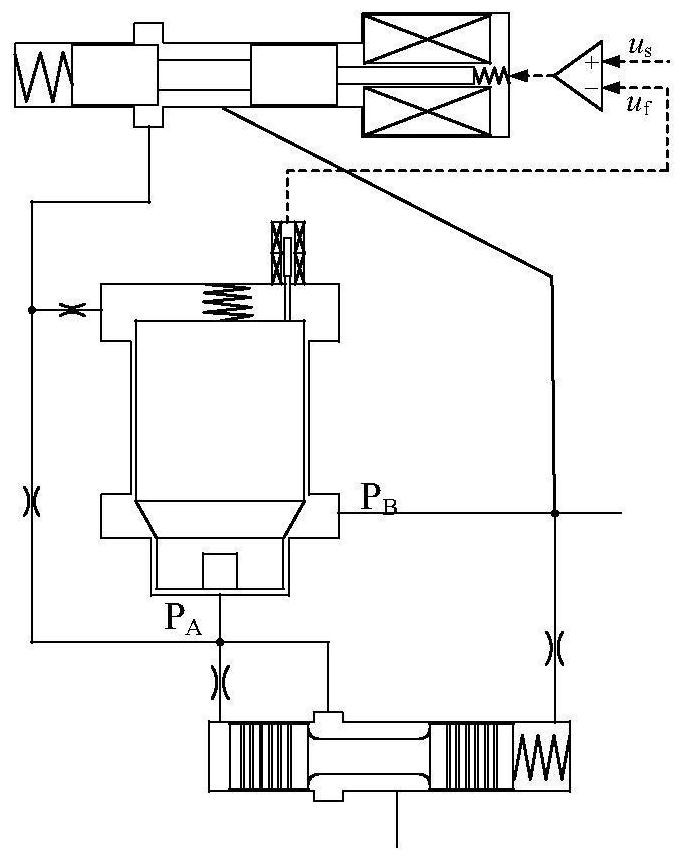

[0036] An electronically controlled and compensated two-way proportional flow valve, comprising a proportional pilot valve 1, a main valve 6 and a first displacement sensor 10;

[0037] Such as Figure 4 As shown, the proportional pilot valve includes the pilot spool 2, the first proportional electromagnet 3, the pilot valve spring 4, the pilot valve body 5, the pilot valve oil inlet A 2 and pilot valve outlet B 2 ;

[0038] Such as Figure 5 As shown, the main valve includes the main valve core 7, the main valve sleeve 8, the main valve return spring 9, the main valve oil inlet P A , main valve oil outlet P B and main valve control chamber P C ; The first displacement sensor 10 is installed on the main valve core 7 to detect the displacement of the main valve core 7; it is characterized in that it also includes an electronic pressure compensation valve 11;

[0039] The electronic pressure compensation valve 11 is a pressure compensation valve controlled by a proportiona...

Embodiment 2

[0050] The second embodiment of an electronically controlled compensation two-way proportional flow valve of the present invention is the same as the first embodiment in terms of structural composition and connection relationship, and the difference is that an electro-hydraulic pressure compensation valve 12 is used.

[0051] Such as Figure 9 As shown, the electro-hydraulic pressure compensation valve 12 includes a displacement sensor 13, a compensation valve body 15, a compensation valve core 16, a spring 17, an oil inlet A, an oil outlet B, and the first control chamber P F , the second control chamber P E and the third control chamber P G The compensation valve core 16 is arranged in the compensation valve body 15, one end of the spring 17 acts on the left end surface C of the compensation valve core 16, and the other end acts on the compensation valve body 15, and forms the first control chamber P with the compensation valve core 16 F , the displacement sensor 13 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com