High speed electrohydraulic open and close valve driven directly by ultra-magnetostriction actuator

A technology of giant magnetostrictive and giant magnetostrictive rods, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of complex temperature rise structure, slow dynamic response speed and low driving efficiency of giant magnetostrictive rods , to improve the response speed and control precision, fast dynamic response speed and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

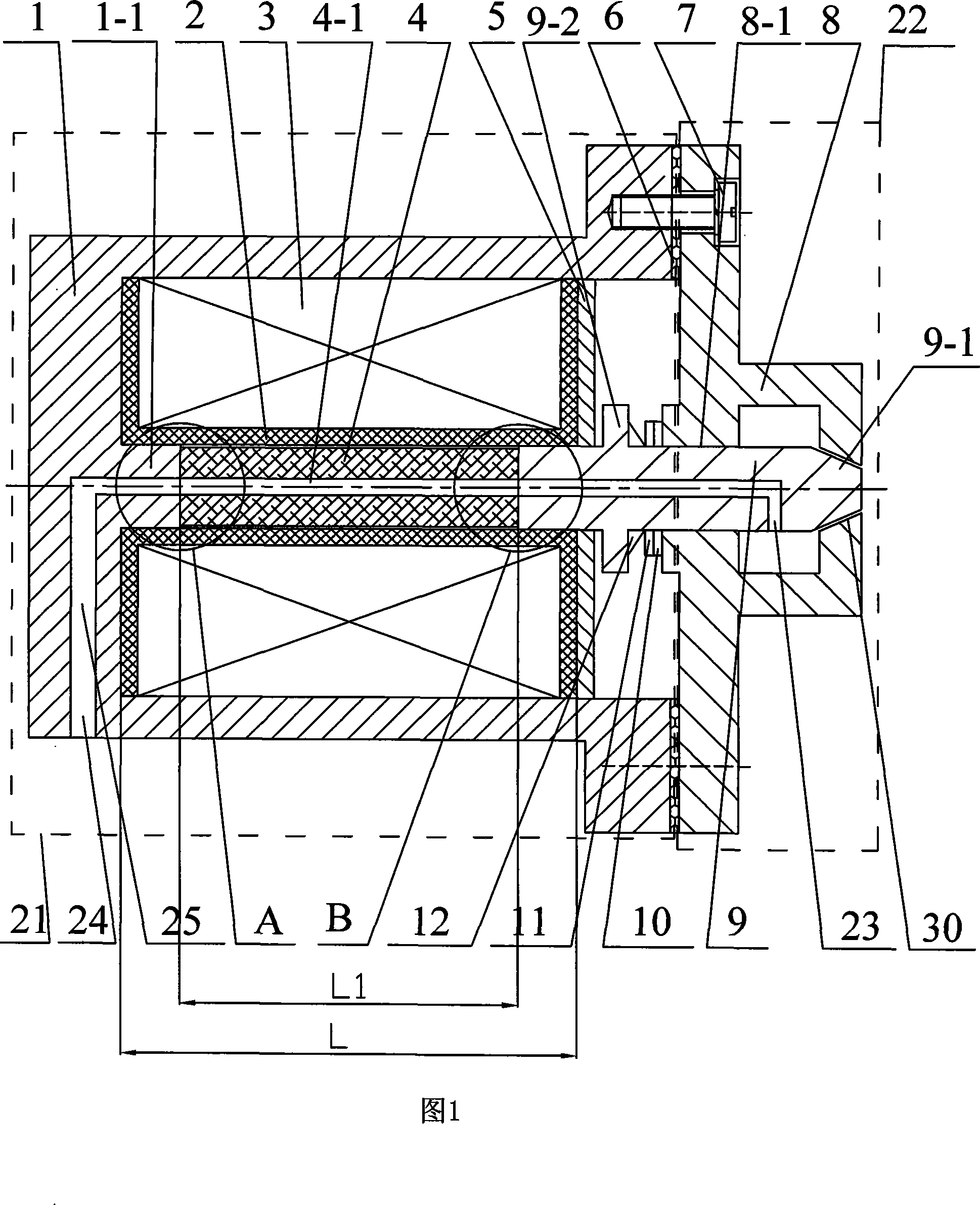

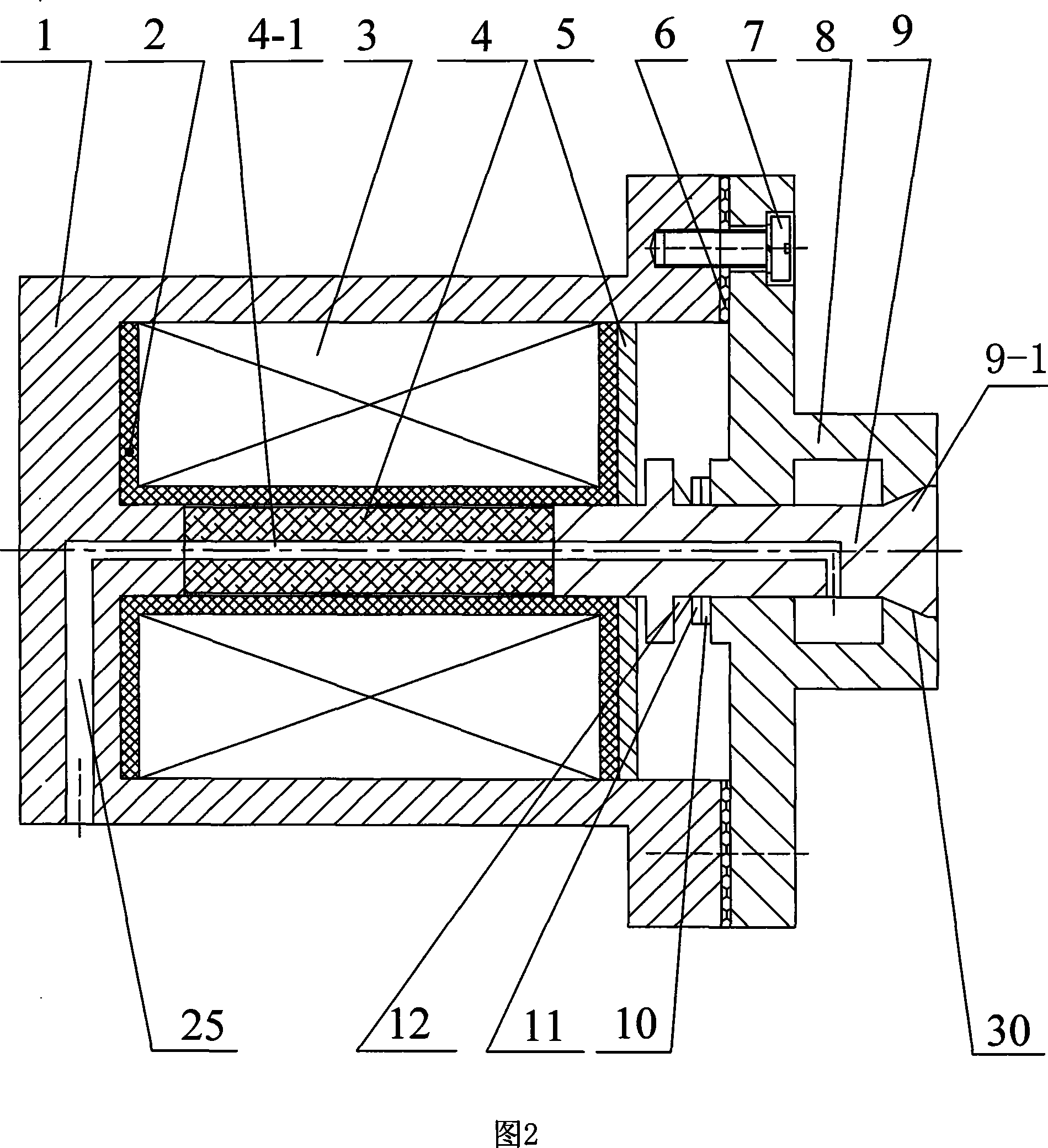

[0007] Embodiment 1: As shown in Figure 1 and Figure 2, the high-speed electro-hydraulic switching valve directly driven by the giant magnetostrictive actuator of this embodiment consists of a giant magnetostrictive actuator (Giant MagnetostrictiveActuator-GMA) 21 and a switch valve 22, the giant magnetostrictive actuator 21 is made up of an actuator housing 1, a coil bobbin 2, a drive coil 3, a giant magnetostrictive rod 4, and a baffle 5, and the switch valve 22 is made up of a valve body 8. The valve core 9 is composed of; the front end of the valve core 9 is installed in the valve body 8, the valve core 9 passes through the through hole 8-1 on the valve body 8, and the rear end of the valve core 9 is connected with the actuator housing 1 The bottom end is fixed together by the giant magnetostrictive rod 4, the front end of the valve core 9 is in contact with the valve 30 on the valve body 8, the coil bobbin 2 is set on the giant magnetostrictive rod 4, and the driving coil ...

specific Embodiment approach 2

[0010] Specific embodiment two: as shown in Figure 1 and Figure 5, the drive coil 3 described in this embodiment is composed of three (odd number) concentric coils with the same inner and outer diameters, and each coil is wound around the coil in turn from left to right on skeleton 2. With such a design, the internal magnetic field distribution of the giant magnetostrictive rod 4 can be improved and the uniformity of the magnetic field can be improved by adopting different current drives in sections. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

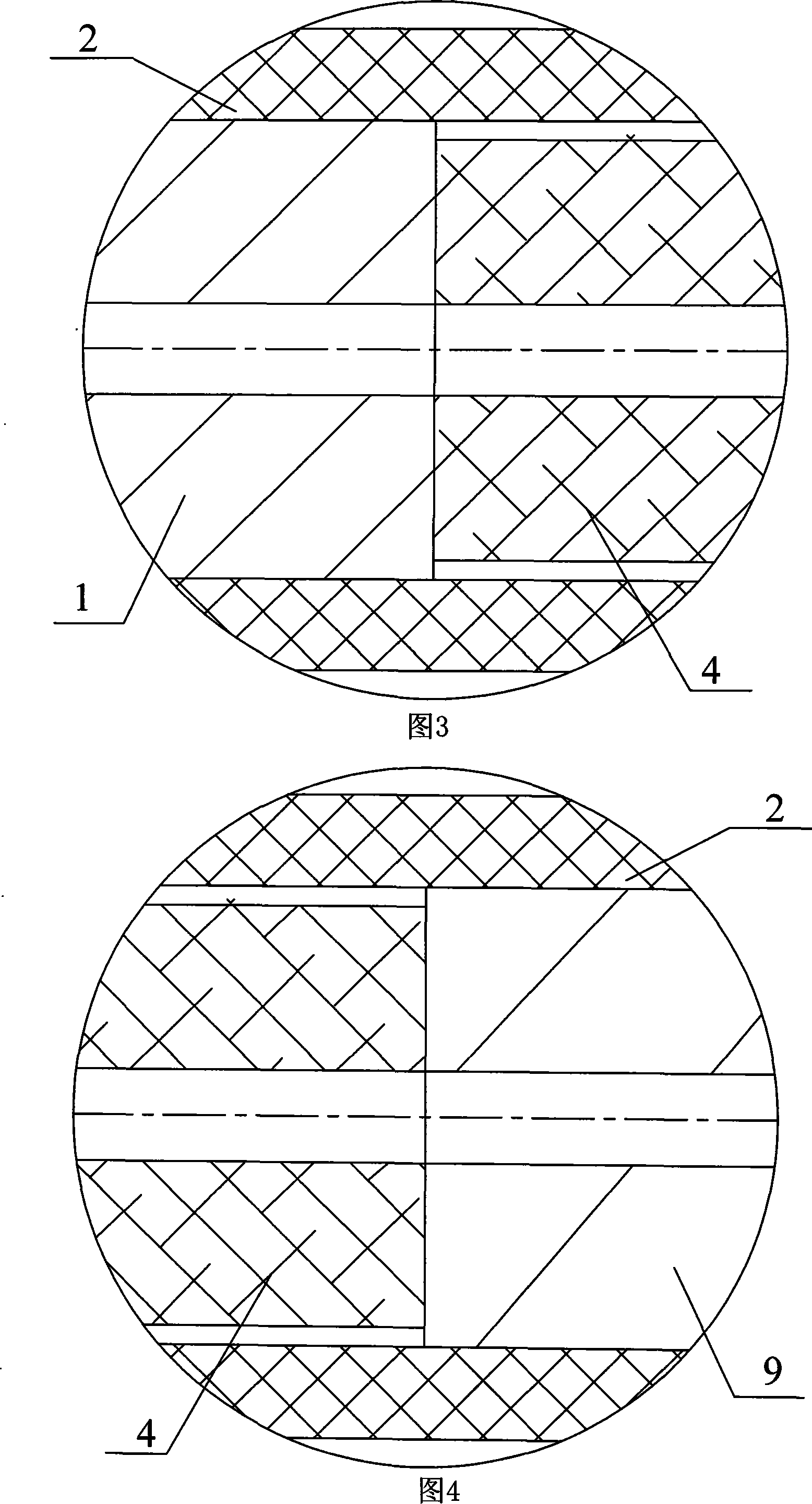

[0011] Specific embodiment three: as shown in Fig. 1, Fig. 3 and Fig. 4, a boss 1-1 is provided on the bottom end of the actuator housing 1 in this embodiment, the boss 1-1, the The boss 1-1 is fixedly connected to the giant magnetostrictive rod 4, and the cross-sectional radius of the boss 1-1 and the valve core 9 is greater than that of the giant magnetostrictive rod 4. Such a design can improve the uniformity of the magnetic field on the contact surface of the giant magnetostrictive rod 4 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com