Semiconductor refrigeration temperature control type ultra- magnetostriction microdisplacement actuator

A giant magnetostrictive, semiconductor technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, fluids using vibration, electrical components, etc., to achieve stable operation, small driving current, and suppression of thermal error output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

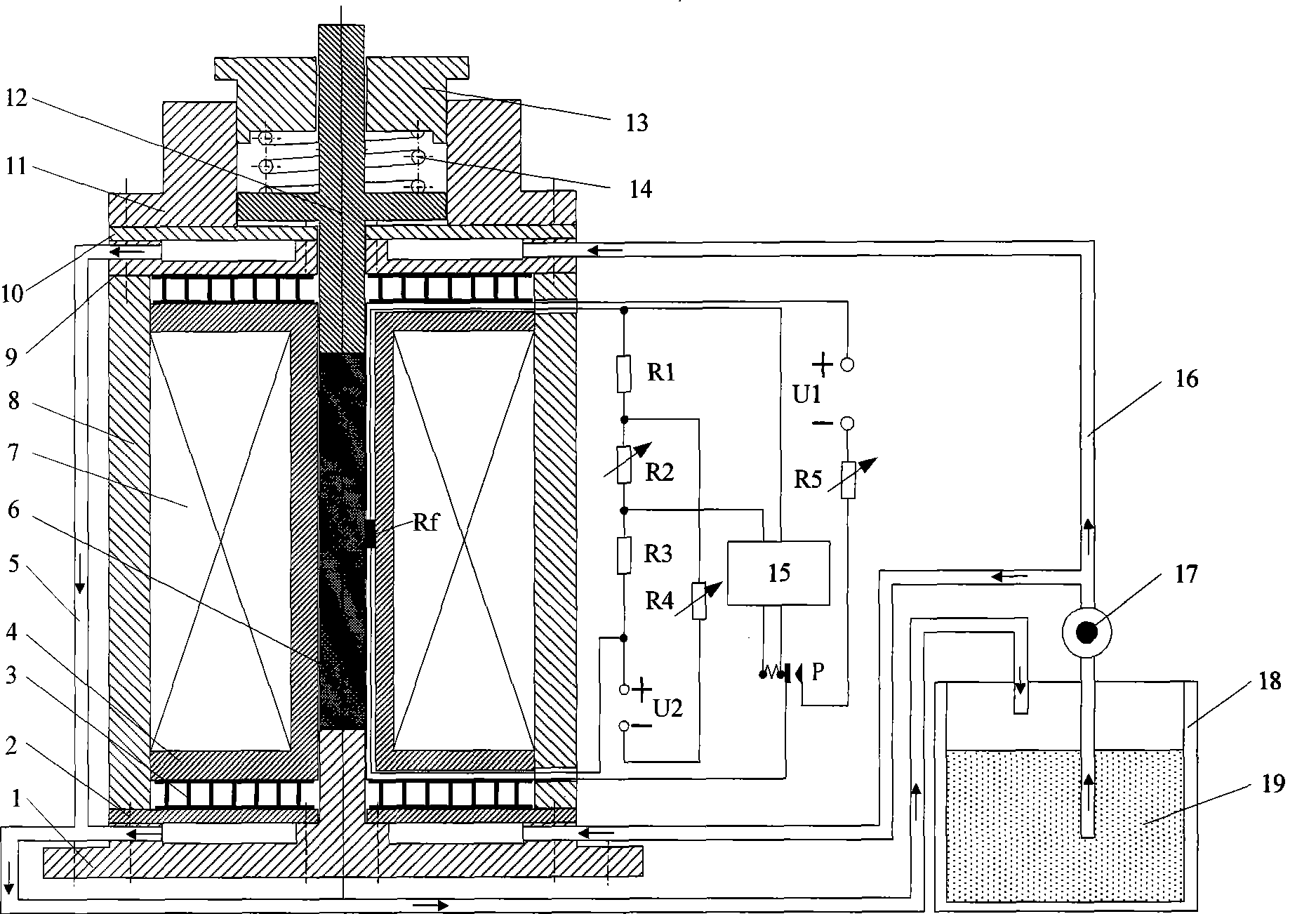

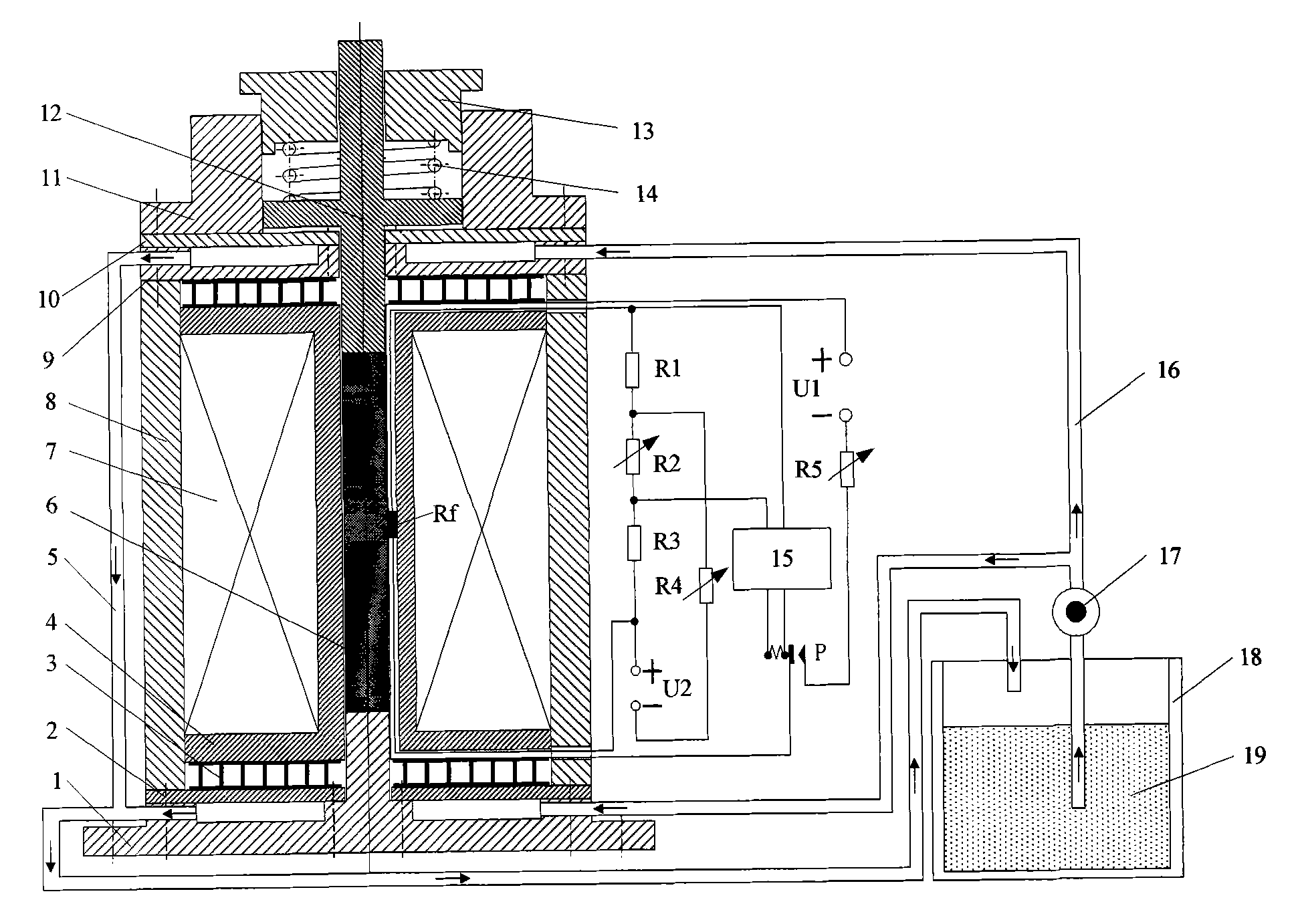

[0015] The preload spring is a cylindrical spring 14 or a disk spring.

[0016] By adjusting the combined preloading device composed of the output push rod 12, the preload spring 14, the upper end cover 11 and the preload nut 13, different preloads can be applied to the giant magnetostrictive rod 6, so that the giant magnetostrictive rod 6 is in the better working condition. Under the action of the input current, the driving coil 7 will generate a driving magnetic field to change the length of the giant magnetostrictive rod 6 . Since the base 1 of the lower cooling water chamber has a supporting effect on the giant magnetostrictive rod 6, the length variation of the giant magnetostrictive rod 6 will be output to the outside through the output ejector rod 13, which is expressed as the displacement of the giant magnetostrictive micro-displacement actuator output.

[0017] Under the action of excitation current, the temperature inside the giant magnetostrictive micro-displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com