Air-cooling temperature control principle based ultra-magnetostriction microfeed driving mechanism

A technology of giant magnetostriction and drive device, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Compensation is complex and other problems, to achieve the effect of small driving current, simple structure and large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

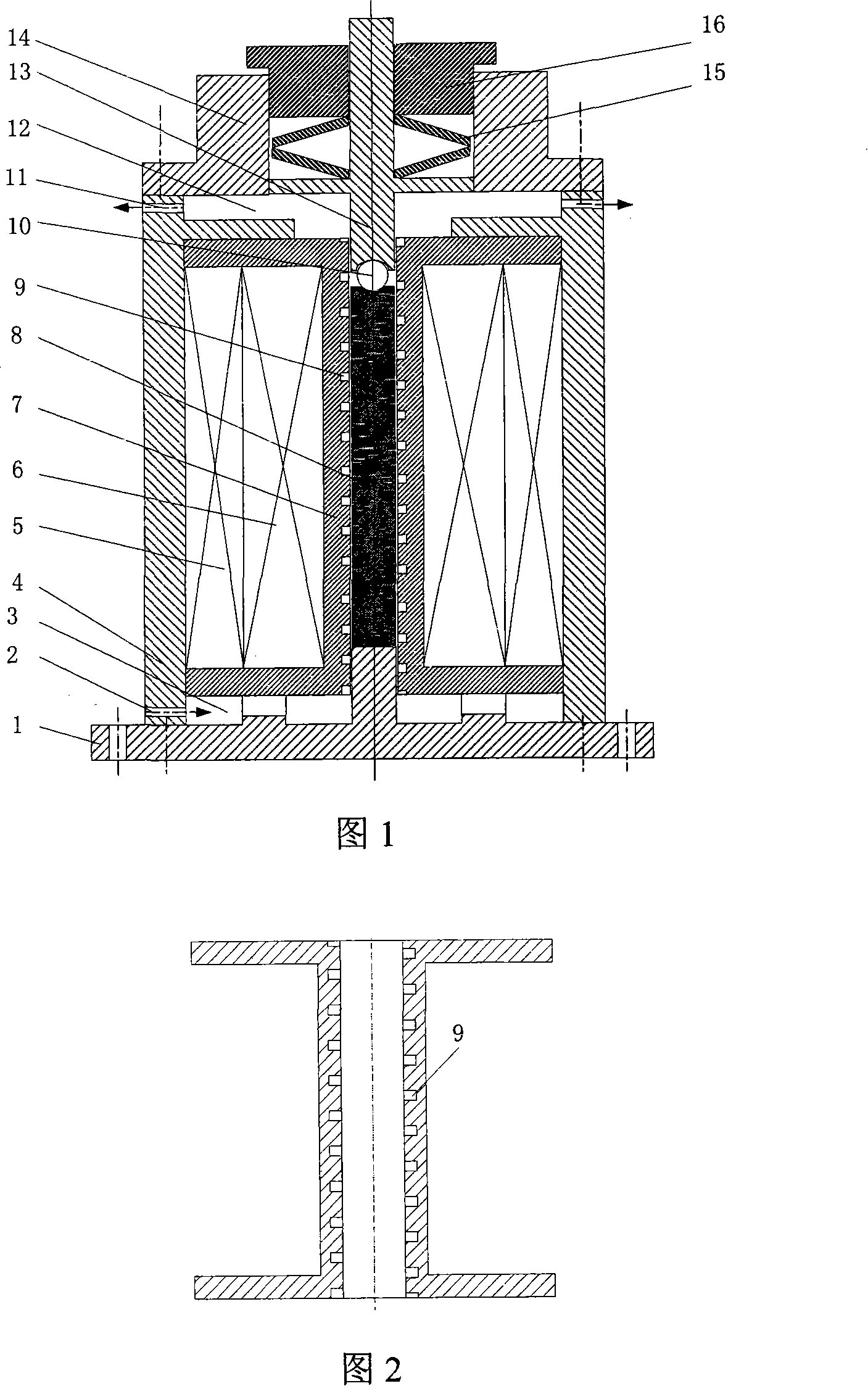

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

[0011] As shown in Figures 1 and 2, the present invention includes a base 1, a lower cooling chamber 3, a housing 4, a bias coil 5, a driving coil 6, a bobbin 7, a giant magnetostrictive rod 8, a steel ball 10, and an upper cooling chamber 12. Cross-shaped output ejector rod 13, upper end cover 14, disc spring 15, preload nut 16; giant magnetostrictive rod 8, steel ball 10 and cross-shaped output ejector rod 13 are installed on the small boss in the center of base 1, Outside the straight rod under the giant magnetostrictive rod 8 and the cross-shaped output ejector rod 9, a coil skeleton 7 with a spiral cooling air channel 9 on the inner wall, a driving coil 6, a bias coil 5 and a casing 4 are sequentially installed from the inside to the outside; Disc spring 15 and preload nut 16 are installed on the upper straight rod of the glyph output ejector rod 13. The upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com