Urea solution metering injector and control method thereof

A solution and urea technology, which is applied to the electronic control of exhaust gas treatment devices, noise reduction devices, exhaust devices, etc., can solve the problems of difficult flow of urea solution, fluctuation of urea solution pressure amplitude, etc., so as to improve control accuracy and prevent device rupture. , the effect of reducing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

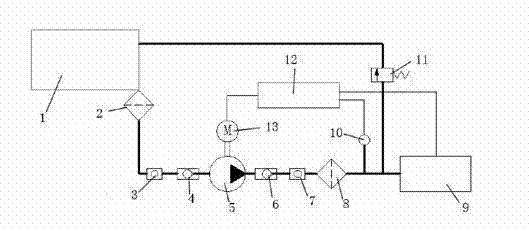

[0023] Such as figure 1 As shown, a urea solution metering injection device includes a pump 5, a urea tank 1, a stepper motor 13 and a nozzle 9, and is characterized in that the outlet of the urea tank 1 passes through the pre-filter 2, the first variable volume Part 3 and the first one-way valve 4 are connected to the inlet end of the pump 5, and the output end of the pump 5 is connected to the nozzle 9 through the second one-way valve 6, the second variable volume part 7 and the filter 8 in sequence , the pump 5 is connected with a stepper motor 13; a pressure valve 11 is provided between the filter 8 and the nozzle 9; a sensor 10 is provided between the nozzle 9 and the filter 8, and the Stepper motor 13 is connected with control unit 12, and described control unit 12 is connected with sensor 10 and nozzle 9, and described control unit 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com