High-precision micro-jet test pipeline device

A test pipeline and micro-jet technology, which is applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of difficult small flow precise control, small flow adjustment characteristics, serious air leakage, etc. , to achieve the effect of broad application prospects, high flow control and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following specific implementation examples are listed in conjunction with the accompanying drawings to further illustrate the technical solution of the present invention.

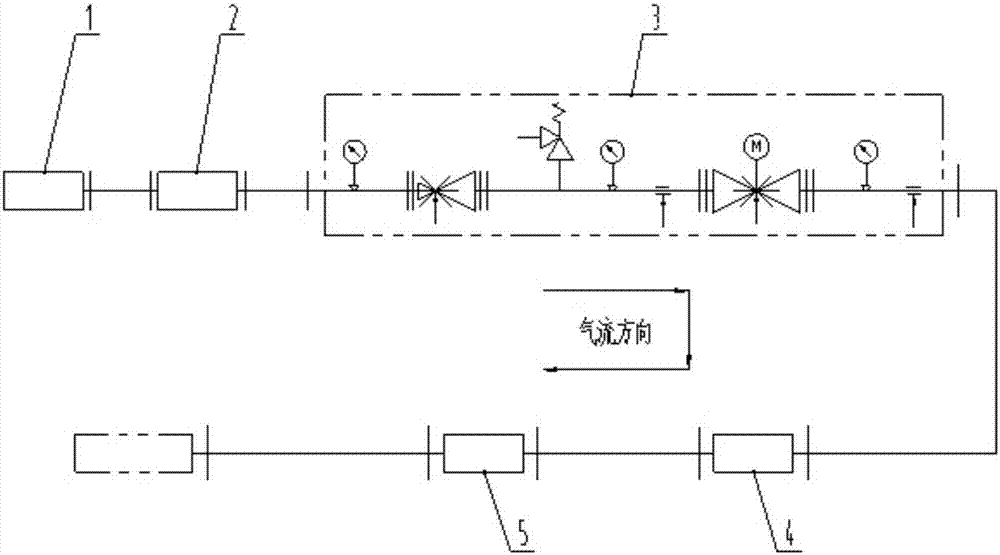

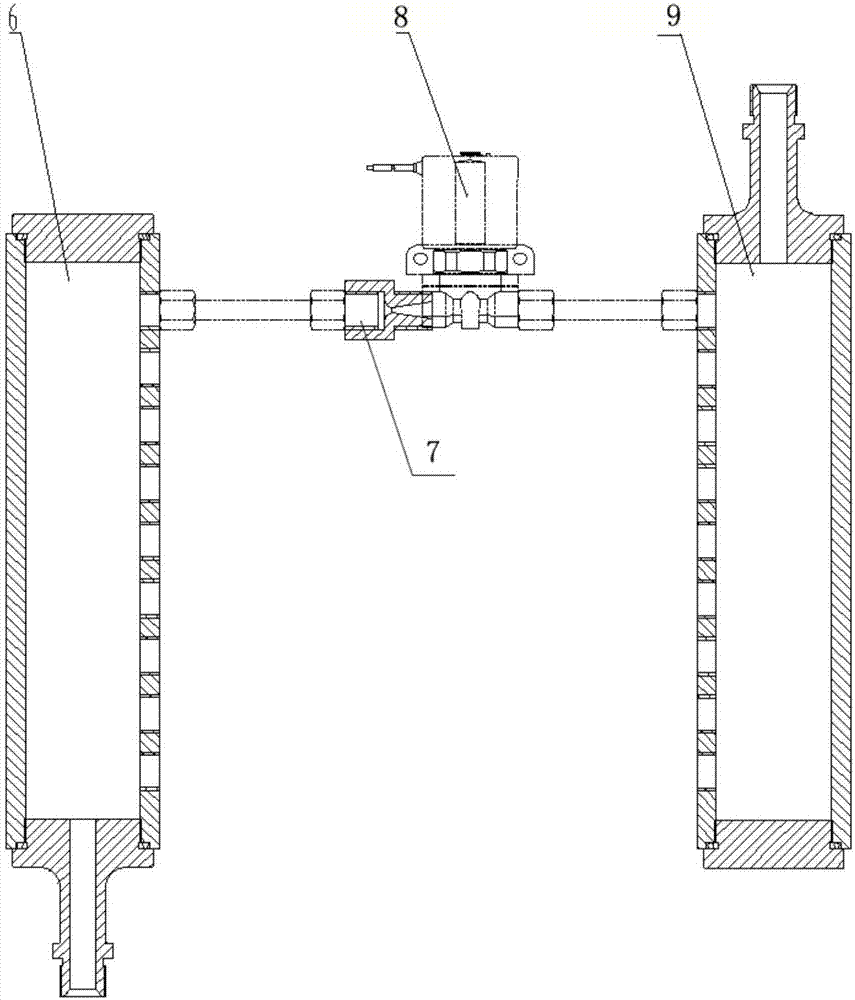

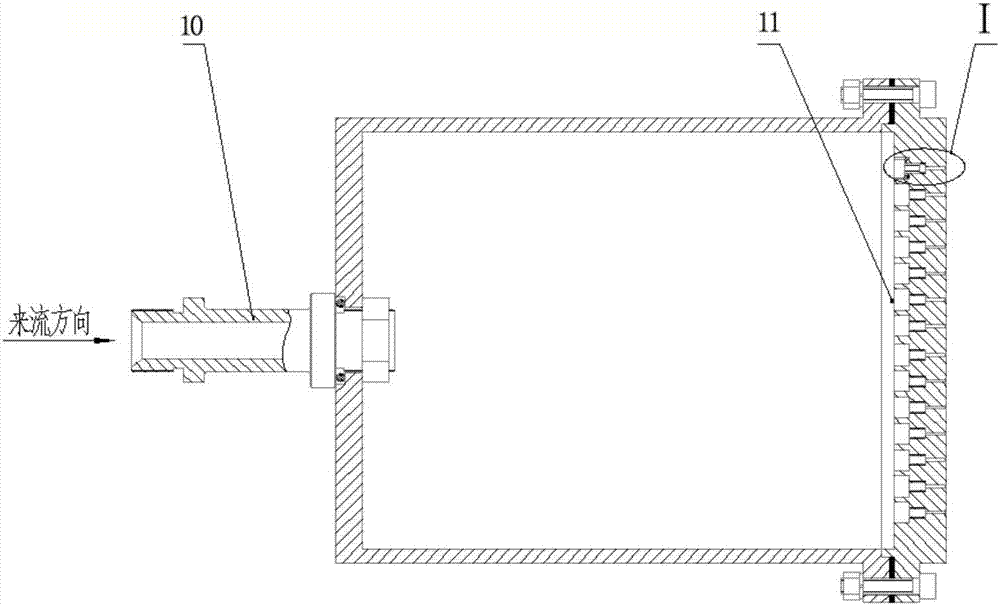

[0012] Such as Figure 1-4 As shown, a high-precision micro-fluidic test pipeline device includes a Coriolis flowmeter, a pressure-reducing regulator valve group, an 8-digit digital valve and a pressure-stabilizing chamber. The high-pressure gas is connected to the Coriolis flowmeter. The flowmeter is connected to the pressure-reducing and stabilizing valve group, the depressurizing and stabilizing valve group is connected to the 8-digit digital valve, the 8-digit digital valve is connected to the pressure-stabilizing chamber, and the pressure-stabilizing chamber is connected to the jet orifice of the test piece. The 8-digit The digital valve includes an air intake chamber, 8 Laval nozzles, 8 solenoid valves and an exhaust air collection chamber. There are 8 air outlet holes in the air inlet cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com