Hydraulic speed regulating valve and hydraulic system

A speed control valve and hydraulic technology, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of heavy workload of self-made speed control valves, and achieve simple structure, high flow control accuracy, and convenient adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

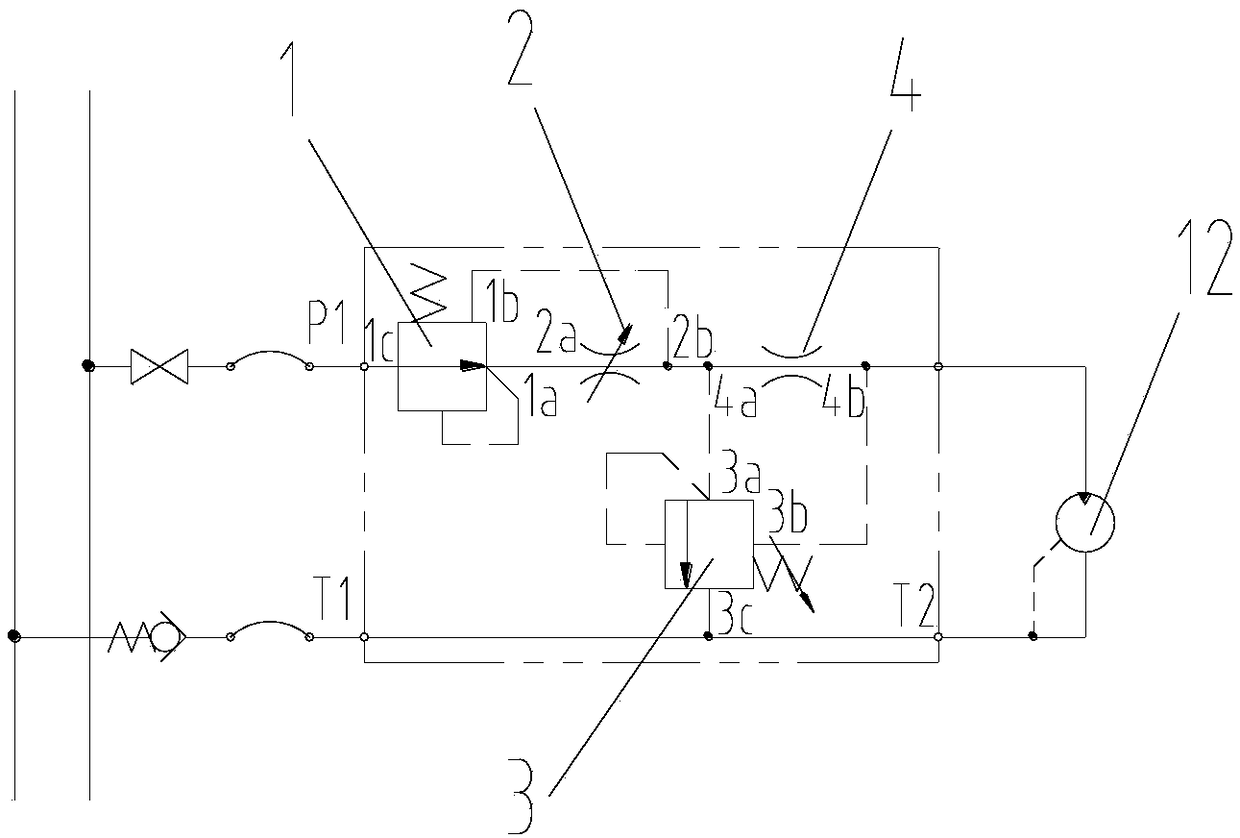

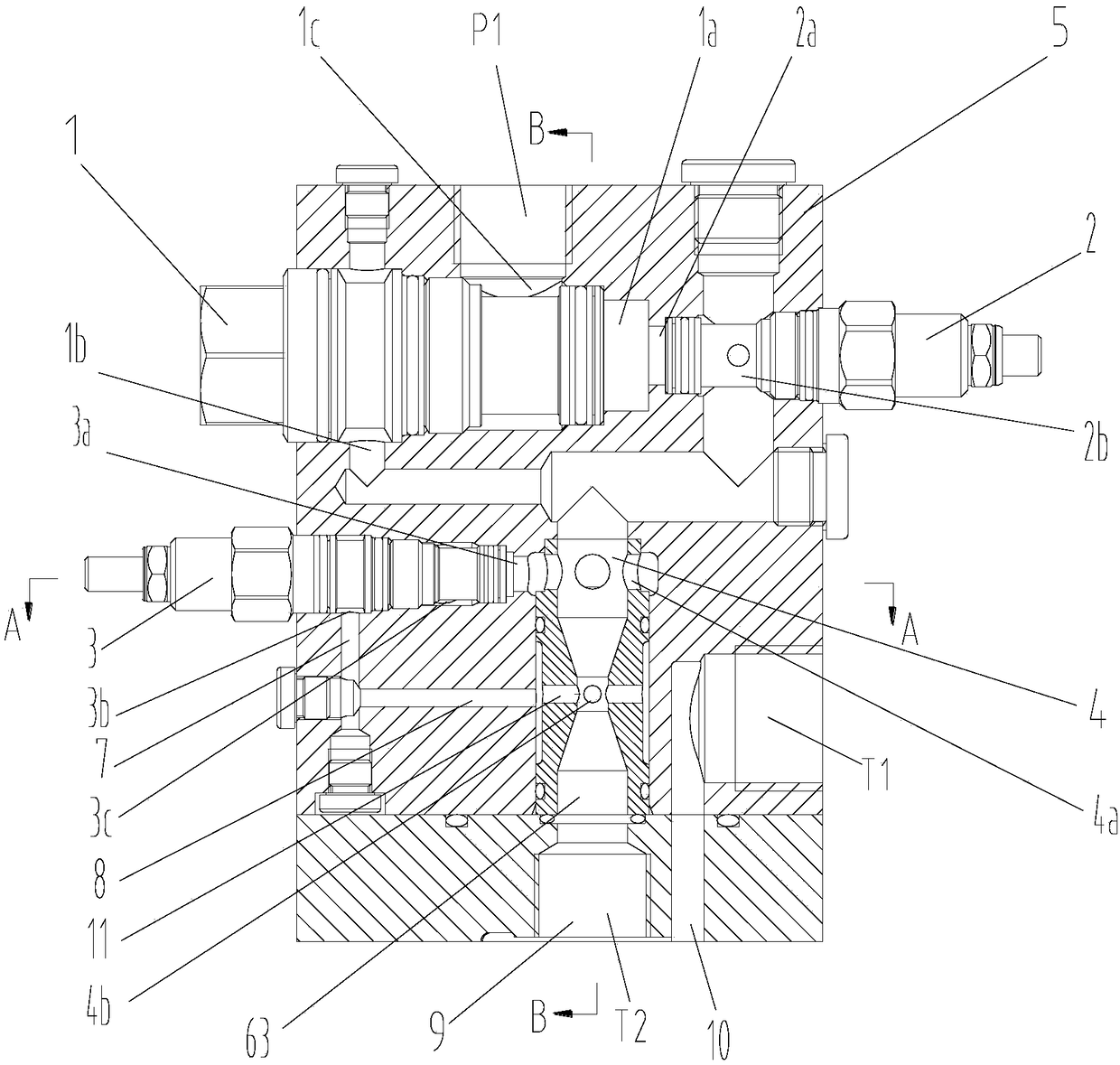

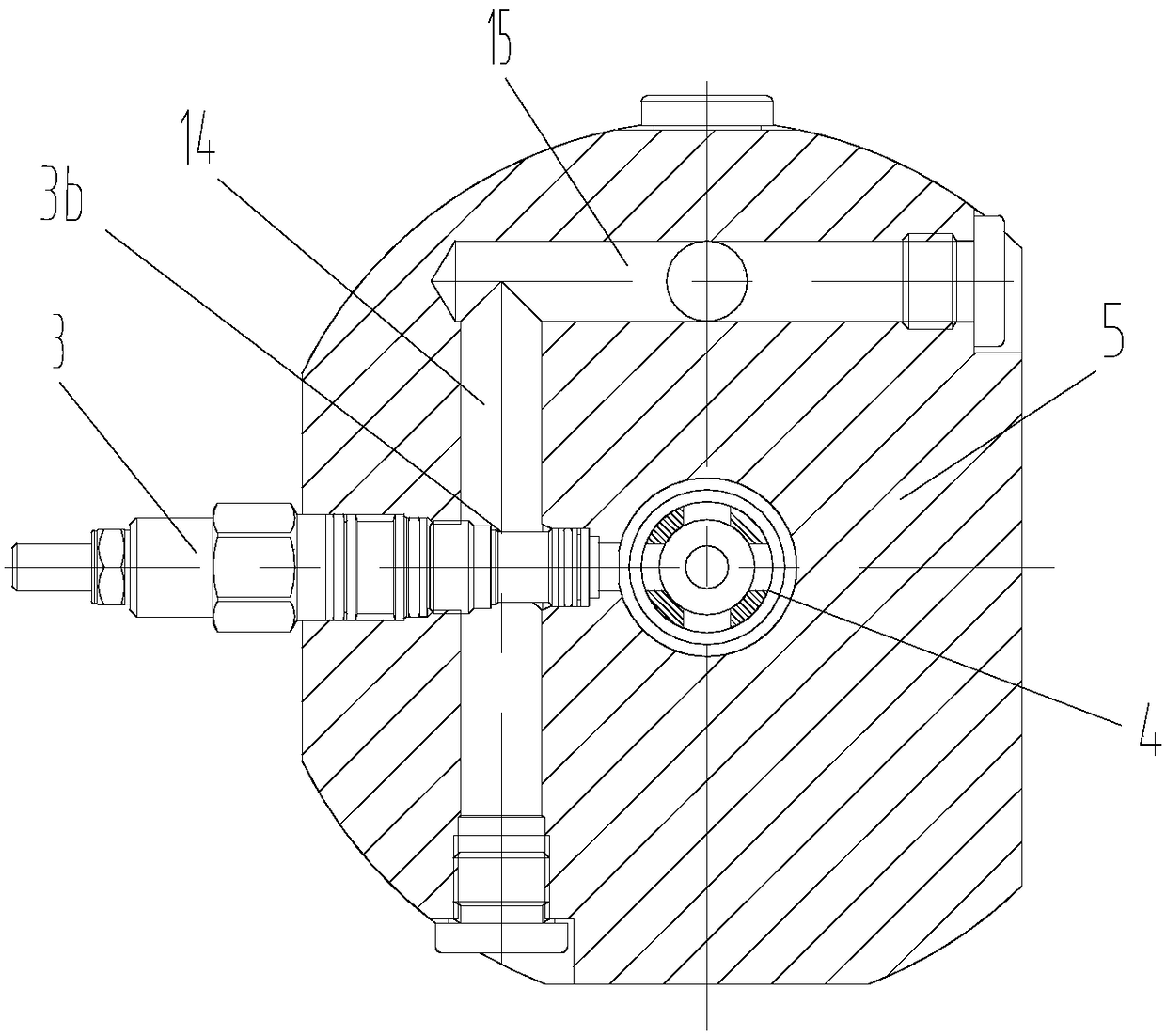

[0027] The embodiment of the present invention provides a hydraulic speed regulating valve, such as figure 1 As shown, the hydraulic speed control valve is suitable for the portable pump drive motor 12 in the hydraulic submersible pump system. The hydraulic speed control valve includes: a pressure reducing valve 1, a throttle valve 2, an overflow valve 3 and a venturi tube 4. The oil outlet 1a of the pressure reducing valve 1 communicates with the oil inlet 2a of the throttle valve 2, the oil drain 1b of the reducing valve 1 communicates with the oil outlet 2b of the throttle valve 2, and the oil inlet of the relief valve 3 3a is connected with the oil outlet 2b of the throttle valve 2, the oil outlet 2b of the throttle valve 2 is also connected with the oil inlet 4a of the Venturi tube 4, and the control oil port 3b of the relief valve 3 is connected with the Venturi tube 4 Throat 4b (see figure 2 ) Is connected, the opening pressure of the overflow valve 3 satisfies the formu...

Embodiment 2

[0041] The embodiment of the present invention provides a hydraulic system, such as Figure 5 As shown, a portable pump drive motor 12 and a concentric tube 13 are included. The concentric tube includes an inner tube 13a and an outer tube 13b. The outer diameter of the inner tube 13a is smaller than the inner diameter of the outer tube 13b, and the outer tube 13b is sleeved outside the inner tube 13a, The oil inlet of the portable pump drive motor 12 communicates with the inner tube 13a of the concentric tube 13, and the oil return port of the portable pump drive motor 12 communicates with the cavity between the outer tube 13b and the inner tube 13a of the concentric tube 13. Combine figure 1 with figure 2 As shown, the hydraulic system also includes: a pressure reducing valve 1, a throttle valve 2, an overflow valve 3, and a venturi tube 4. The oil outlet 1a of the pressure reducing valve 1 communicates with the oil inlet 2a of the throttle valve 2, the oil drain 1b of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com