Microfluid active control valve with toroid boundary

An active control, torus technology, applied in diaphragm valves, valve devices, valve details, etc., can solve problems such as sudden drop in pump flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

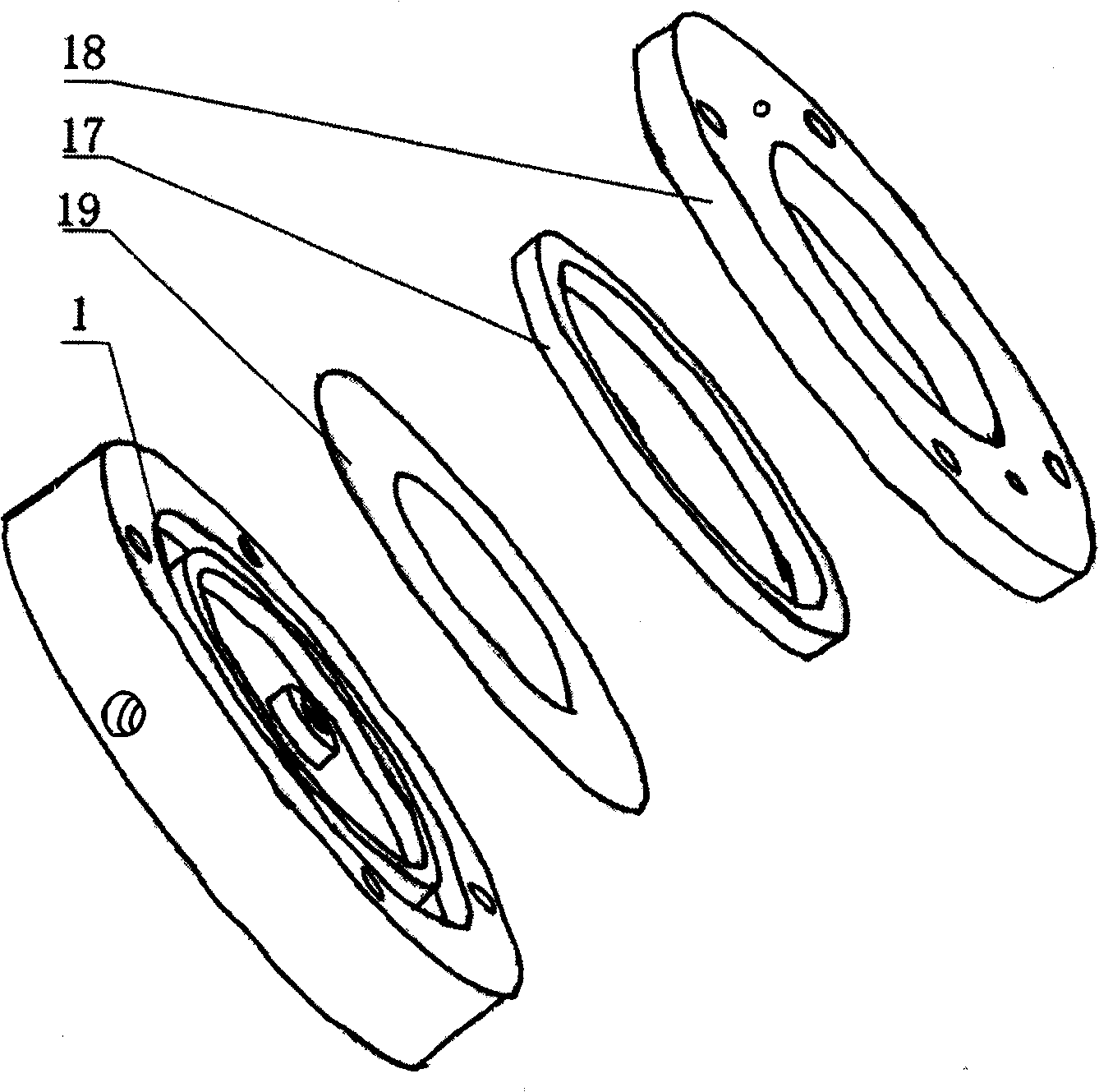

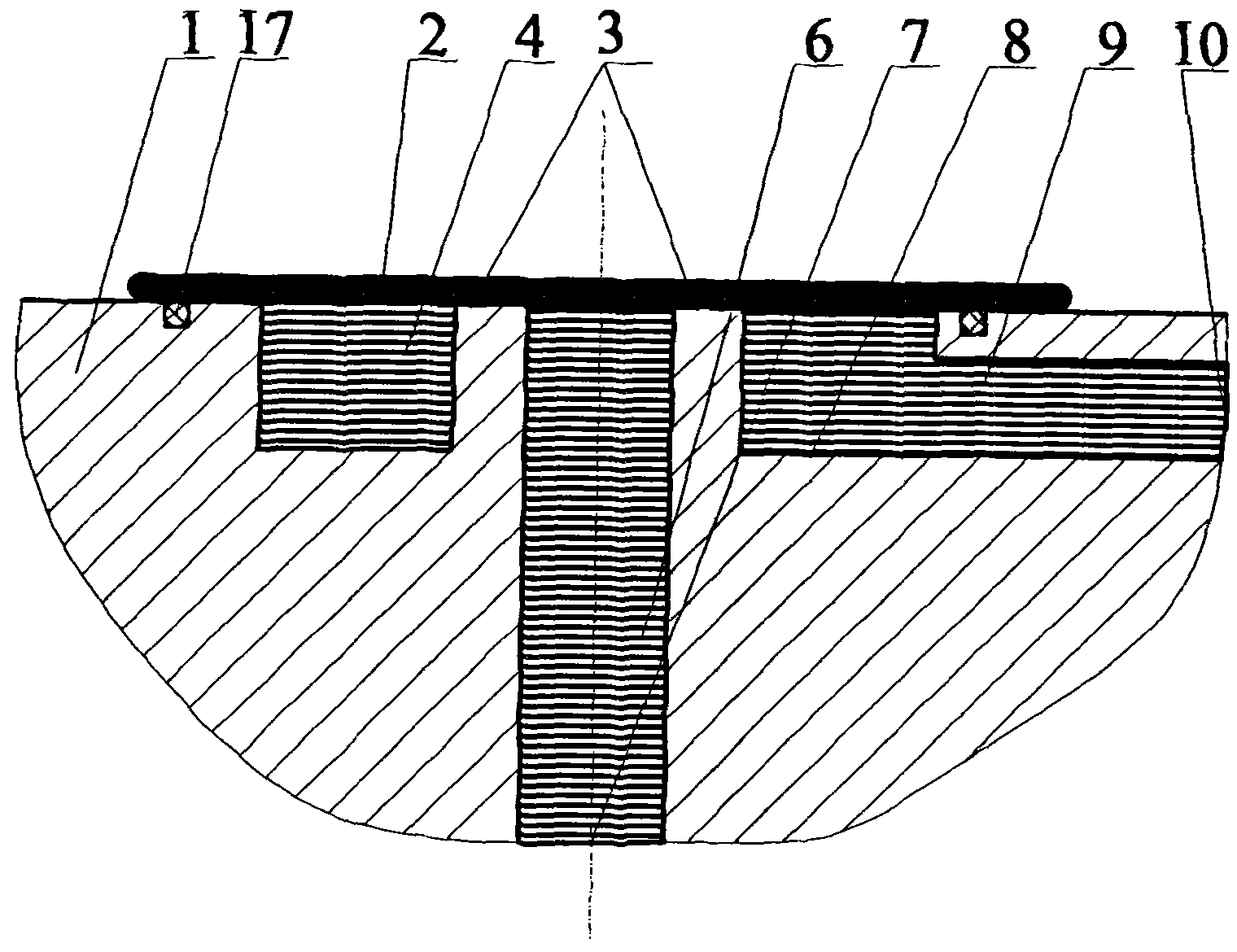

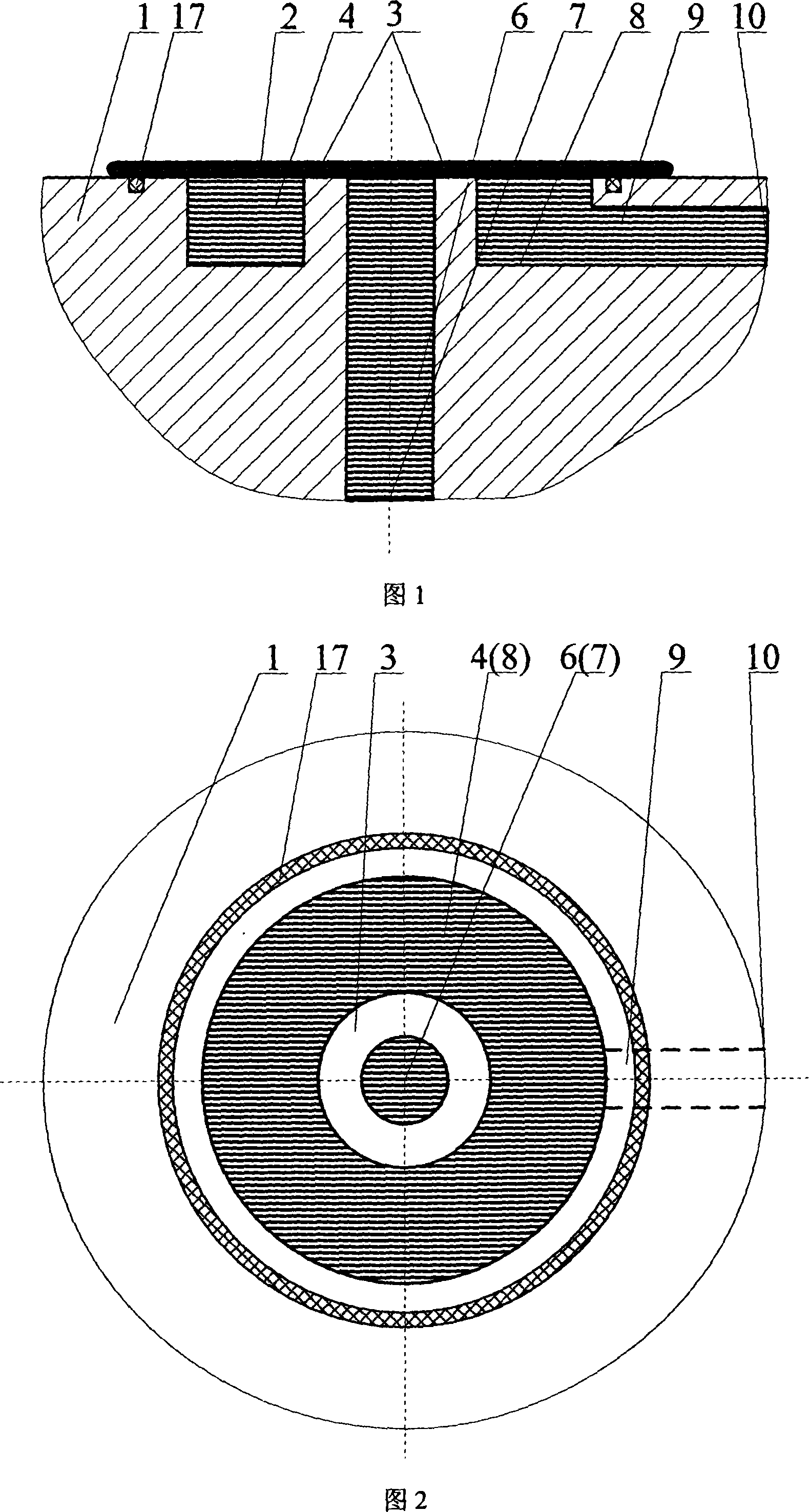

[0033] Referring to the accompanying drawings, the specific implementation of the piezoelectric valve of the present invention will be described in detail below.

[0034] In the accompanying drawings: 1 is the valve body, 2 and 21 are thin film actuators, 3 is the boundary of the torus, 4 is the fluid, 5 and 11 are the flow direction of the microfluid, 6 is the liquid inlet channel (liquid outlet channel), and 7 is the Liquid inlet (liquid outlet), 8 is a fluid cavity, 9 is a liquid outlet channel (liquid inlet channel), 10 is a liquid outlet (liquid inlet), 12, 22 are elastic diaphragms, 13 is a piezoelectric ceramic circle Disc, 14 is wire, 15 is glue for fixing wire, 16 is wire fixing clip, 17 is sealing ring, 18 is valve cover, 19 is piezoelectric vibrator, 20 is connecting bolt, 23 is linear electric controllable actuator, 24 places the ring for the sealing ring, and 25 is the boss of the ring surface.

[0035] Referring to accompanying drawings 1 and 2 (a top view with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com