Hydraulic drive device and system

A driving device and hydraulic technology, which is applied in fluid pressure actuators, servo motors, mechanical equipment, etc., can solve problems such as energy waste and hydraulic oil leakage, and achieve the effects of saving energy and improving pressure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to help those skilled in the art to accurately understand the claimed subject matter of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

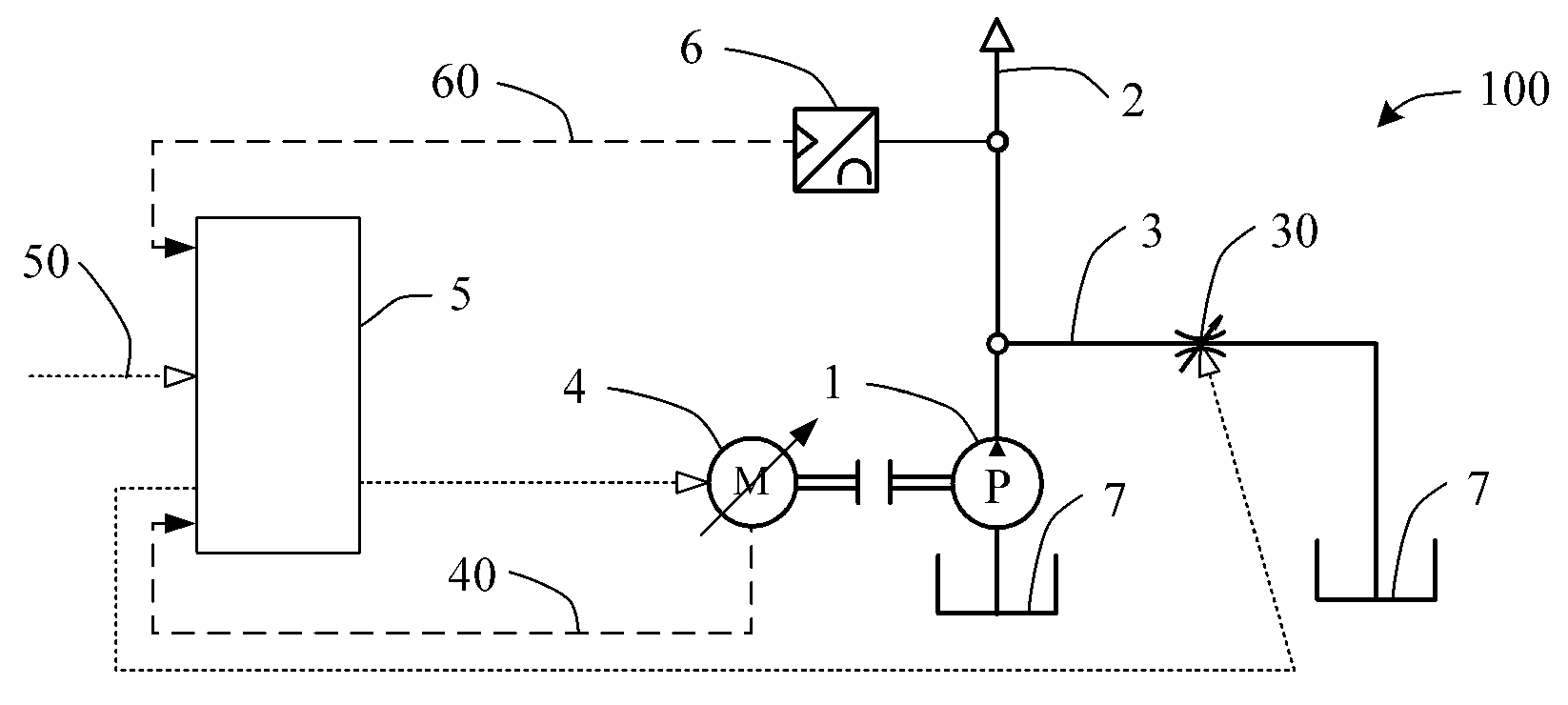

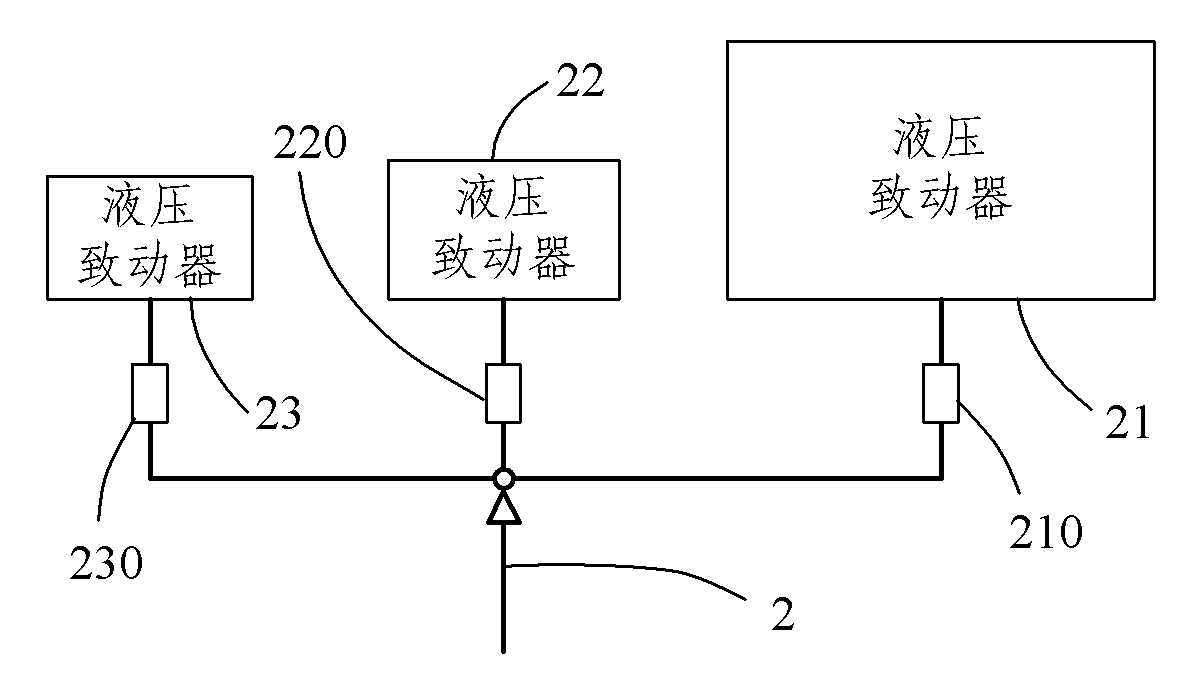

[0025] figure 1 A schematic diagram showing a hydraulic drive device according to an embodiment of the present invention. Such as figure 1 As shown, a hydraulic drive device 100 according to a specific embodiment of the present invention includes a hydraulic pump 1, a hydraulic bypass 3 and a control unit 5, wherein the hydraulic pump 1 pumps hydraulic fluid from the reservoir 7 for connection to the required The hydraulic output line 2 of the driven hydraulic actuator, the hydraulic bypass 3 is connected from the hydraulic output line 2 to the liquid reservoir 7, the hydraulic bypass 3 is provided with an adjustable flow device 30, the adjustable flow device 30 can be a system , valves or other devices. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com