Floor production method

A board production and stage technology, applied in the direction of chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as loose bonding, high defective rate, waste of utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

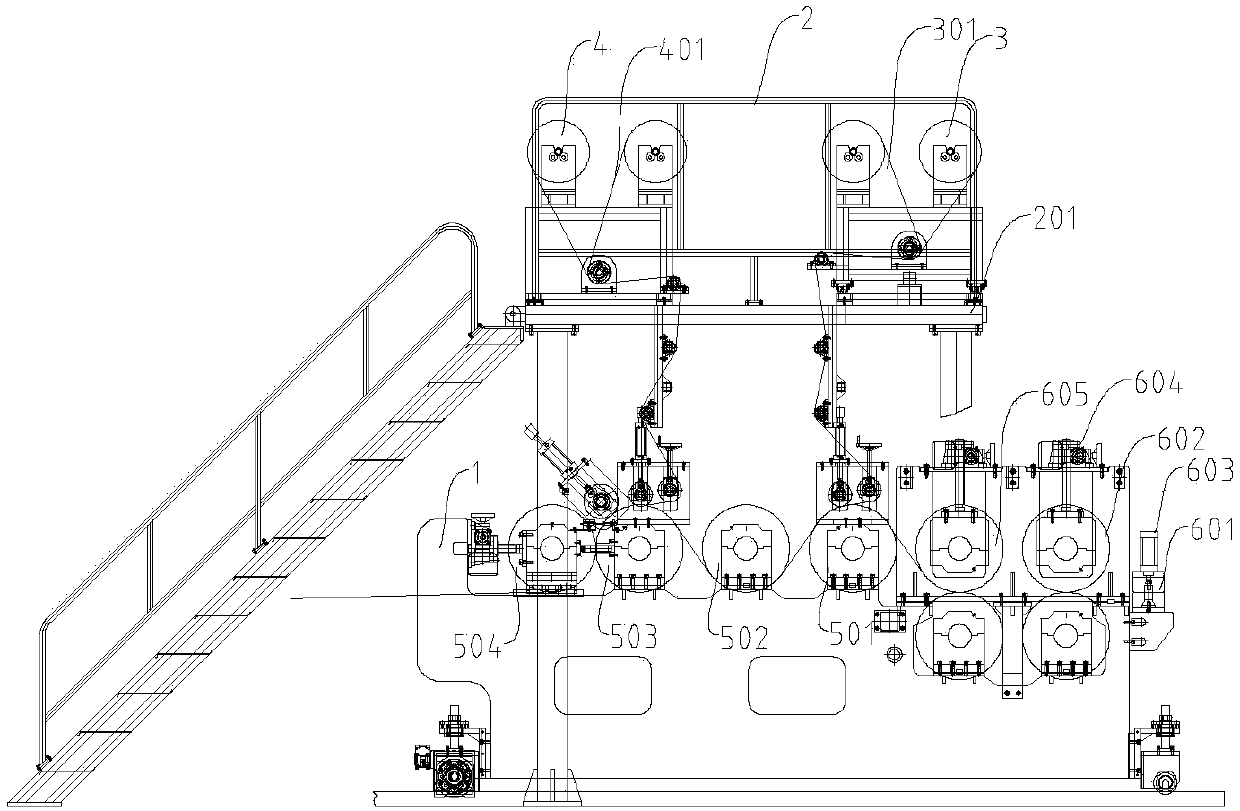

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the embodiments described in the specific implementation are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0026] The invention provides a production process of a separated film-coated plate.

[0027] Before starting processing, heat and keep warm the extruder, mold and other equipment in advance to ensure that the material is extruded from the powder into the solution. If the temperature is not enough to start the machine, it is easy to cause damage to the extruder screw and reducer or even scrap it. Concrete plate production method comprises the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com