Patents

Literature

80results about How to "Has a plasticizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of modified monomer cast (MC) nylon 6 blending material

The invention discloses a preparation method of a modified monomer cast (MC) nylon 6 blending material. The MC nylon 6 blending material comprises the components by material ratio: 100 parts of caprolactam monomer, 20-40 parts of recycled polyethylene, 5-10 parts of compatibilizer, 20-40 parts of dimethylbenzene, 0.2-0.5 part of sodium hydroxide and 0.2-0.5 part of activating agent; the preparation method of the modified MC nylon 6 blending material comprises the steps of: heating the caprolactam monomer, melting, dehydrating the melted caprolactam monomer, and continuously dehydrating after the sodium hydroxide is added; then, adding the recycled polyethylene and the compatibilizer, stirring and leading the recycled polyethylene to be fully mixed in the caprolactam monomer melt until the recycled polyethylene is evenly dispersed; and finally, adding the activating agent, rapidly and evenly mixing, pouring the obtained mixture into a mould, and obtaining the recycled polyethylene / MC nylon 6 blending material. The recycled polyethylene is modifier, so that the production cost of the blending material is greatly reduced, and the blending material is not influenced by few impurities in the modifier; furthermore, the prepared blending material is very stable in performance and quality as well as higher in shock resistance.

Owner:李刚 +1

High-abrasion-resistant modified polyurethane cable material

InactiveCN104356637AImprove wear resistanceImprove cold resistancePlastic/resin/waxes insulatorsNatural resin chemical modificationAntioxidantDibenzoyl Peroxide

The invention discloses a high-abrasion-resistant modified polyurethane cable material, which comprises the following components in parts by weight: 75-90 parts of a polyurethane elastomer, 3-8 parts of acrylonitrile-butadiene rubber, 3-10 parts of chlorosulfonated polyethylene, 10-25 parts of polyvinylidene fluoride, 20-35 parts of modified attapulgite, 20-35 parts of silicon carbide, 5-12 parts of titanium dioxide rutile, 5-15 parts of crystal whiskers, 3-8 parts of eicosanoic abietate, 1-3 parts of triethyl citrate, 5-10 parts of acetyl-tri-n-butyl citrate, 2-6 parts of a coupling agent, 0.5-1.3 parts of zinc oxide, 0.3-0.8 part of stearic acid, 2-6 parts of zinc borate, 1-5 parts of red phosphorus, 0.6-2.5 parts of nano aluminum hydroxide, 0-0.8 part of an antioxidant, 0.5-1.3 parts of benzoyl peroxide, 0.3-2.5 parts of an anti-aging agent and 0.5-1.6 parts of an accelerant. The high abrasion-resistant modified polyurethane cable material disclosed by the invention is high in abrasion resistance, good in cold resistance and long in service life.

Owner:ANHUI DUJIANG CABLE GROUP

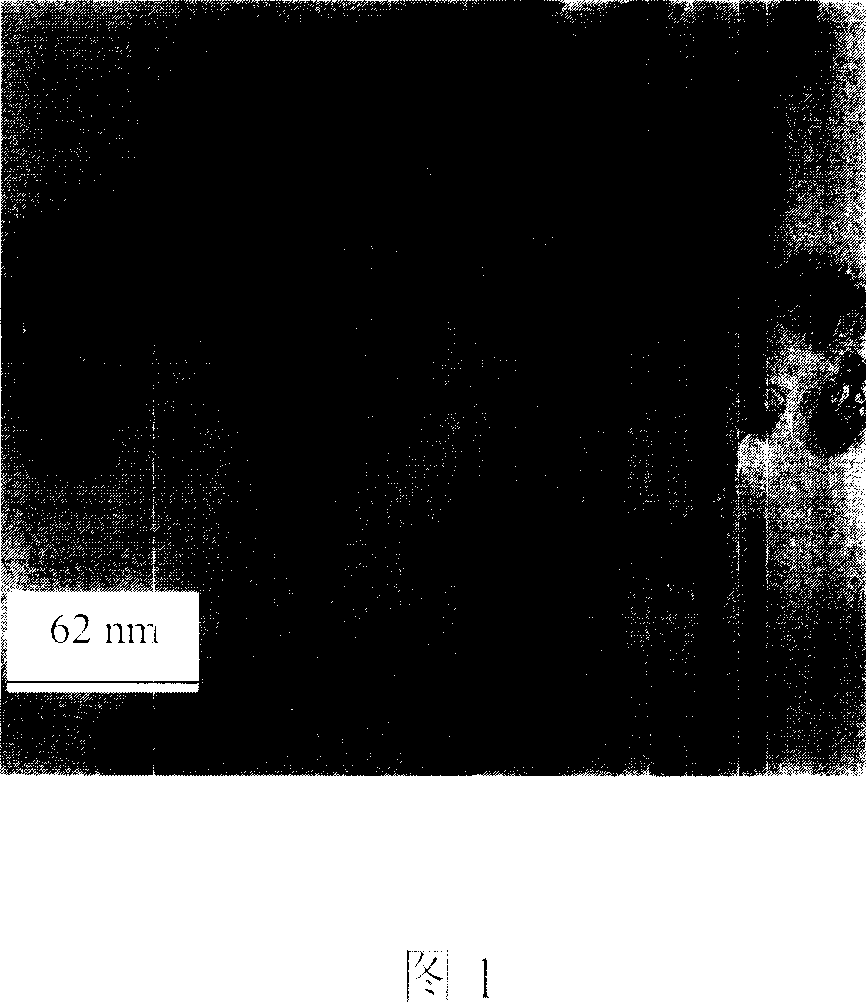

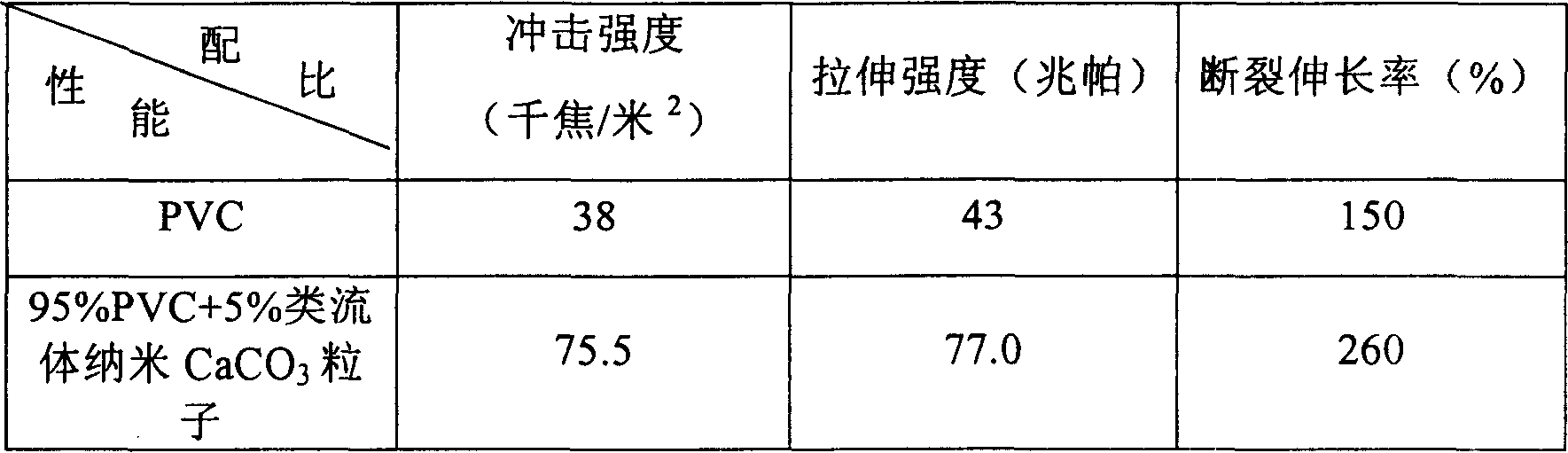

Composite material of similar fluid inorganic nano particle and polymer and preparation thereof

The invention discloses a composite material of like-fluid inorganic nanometer particle and polymer and preparing method, which is characterized by the following: the composite material is consists of m parts of like-fluid inorganic nanometer particle and 100-m parts of thermoplastic polymer, which are mixed at melting temperature+-20DEG C for once forming (0<m<=10); the polymer concludes chloroethylene, polyethylene, polypropylene, polystyrene, nylon and polyester; the inorganic nanometer particle concludes nanometer calcium carbonate, nanometer silicon dioxide and nanometer titanium dioxide.

Owner:WUHAN UNIV OF TECH

Nano high-air-tightness compressive film and preparation method thereof

The invention discloses a nanometer high-air-tightness compressive film, which consists of the following components: PVC (Polyvinyl Chloride) resin, DOP (Dioctyl Phthalate), DBP (Dibutyl Phthalate), DCHP (Dicyclohexyl Phthalate), a stabilizer, modified nanometer kaolin, calcium carbonate and other aids. The nanometer high-air-tightness compressive film is prepared by performing a calendaring process, an attaching process, a cooling step and a coiling step on each component. The nanometer high-air-tightness compressive film has the advantages that: a DOP-DBP-DCHP compound plasticizer is adopted, so that PVC resin is fully plasticized; the DCHP plays a role in plasticizing, and contributes to making a PVC film structure denser and enhancing the air tightness of the compressive film; the air tightness of the compressive is further improved by adopting the modified nanometer kaolin, and superior physical and mechanical performance of the compressive film is achieved simultaneously; and high-strength industrial polyester screen cloth is taken as an intermediate reinforcing material, so that compressive film provided by the invention has extremely high compressive strength.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

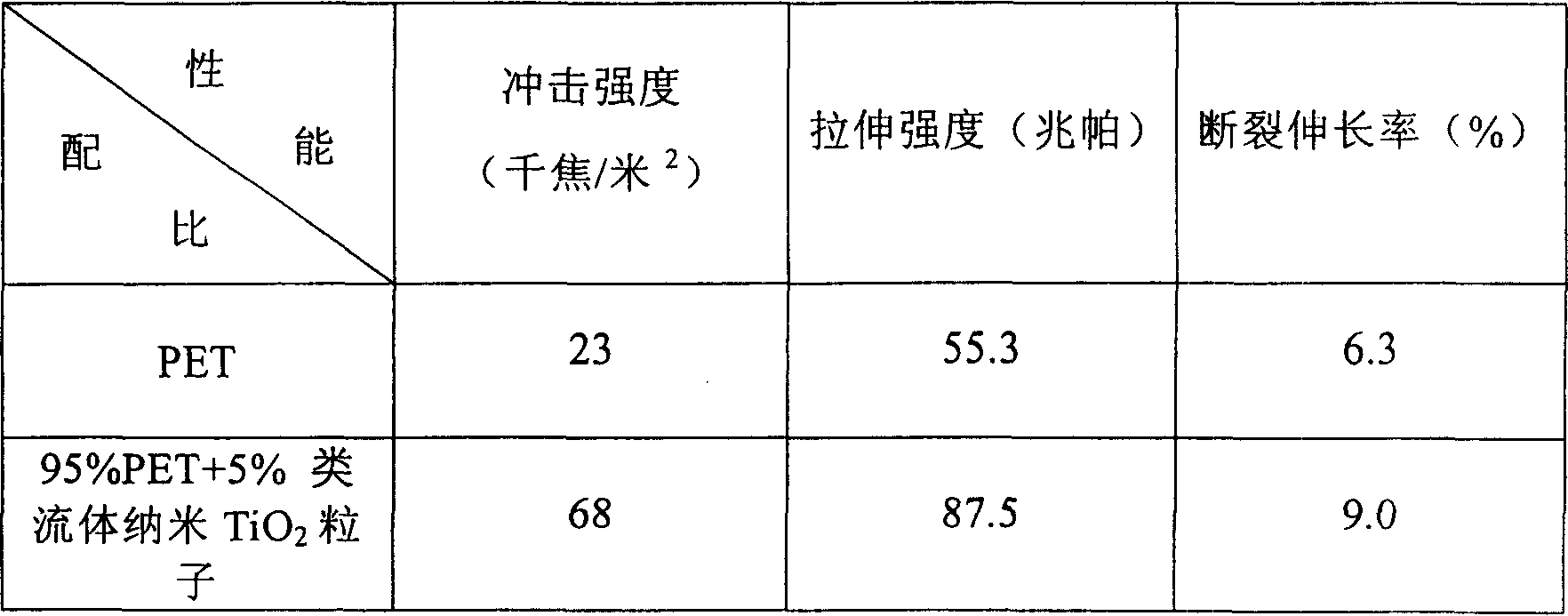

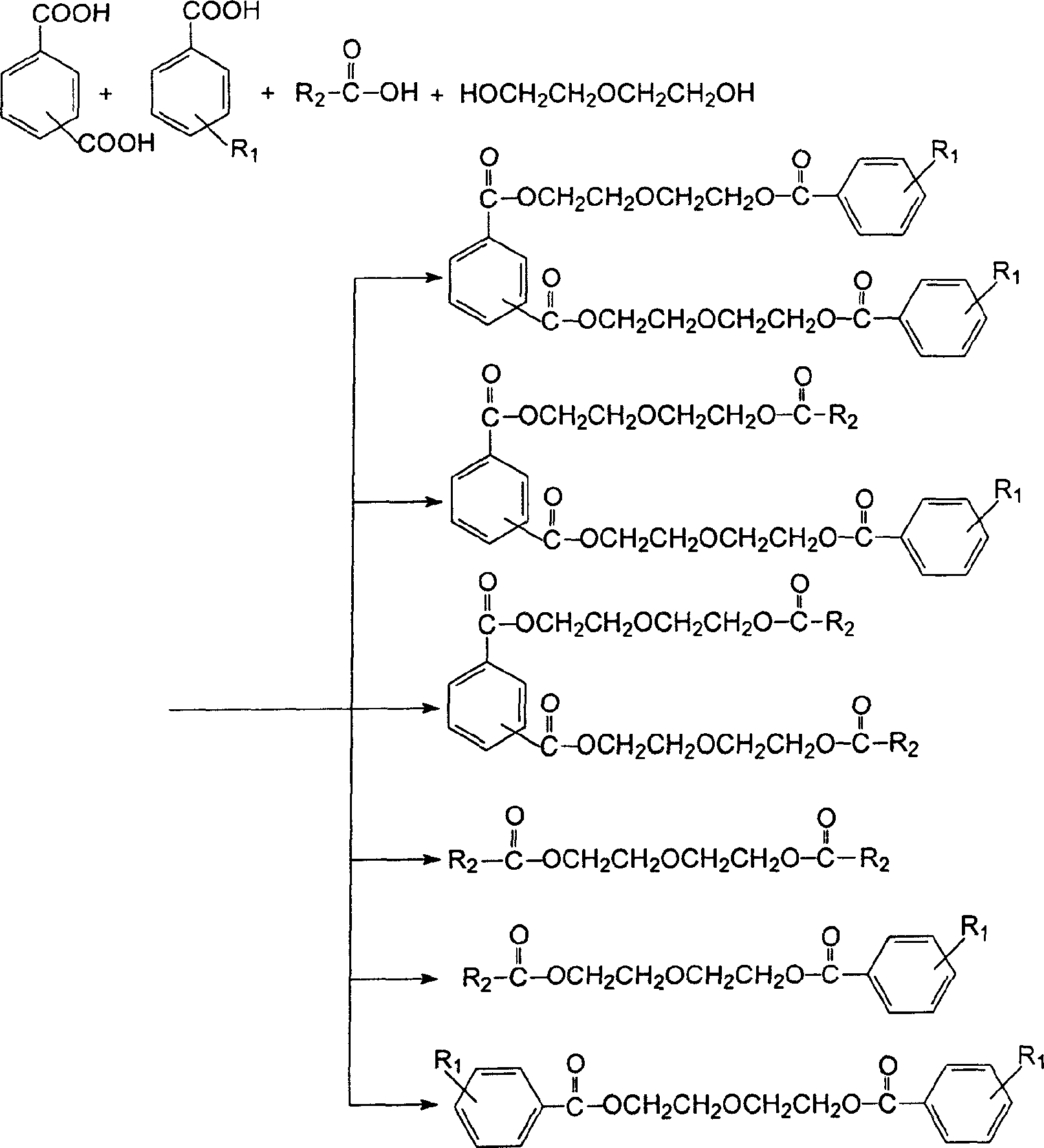

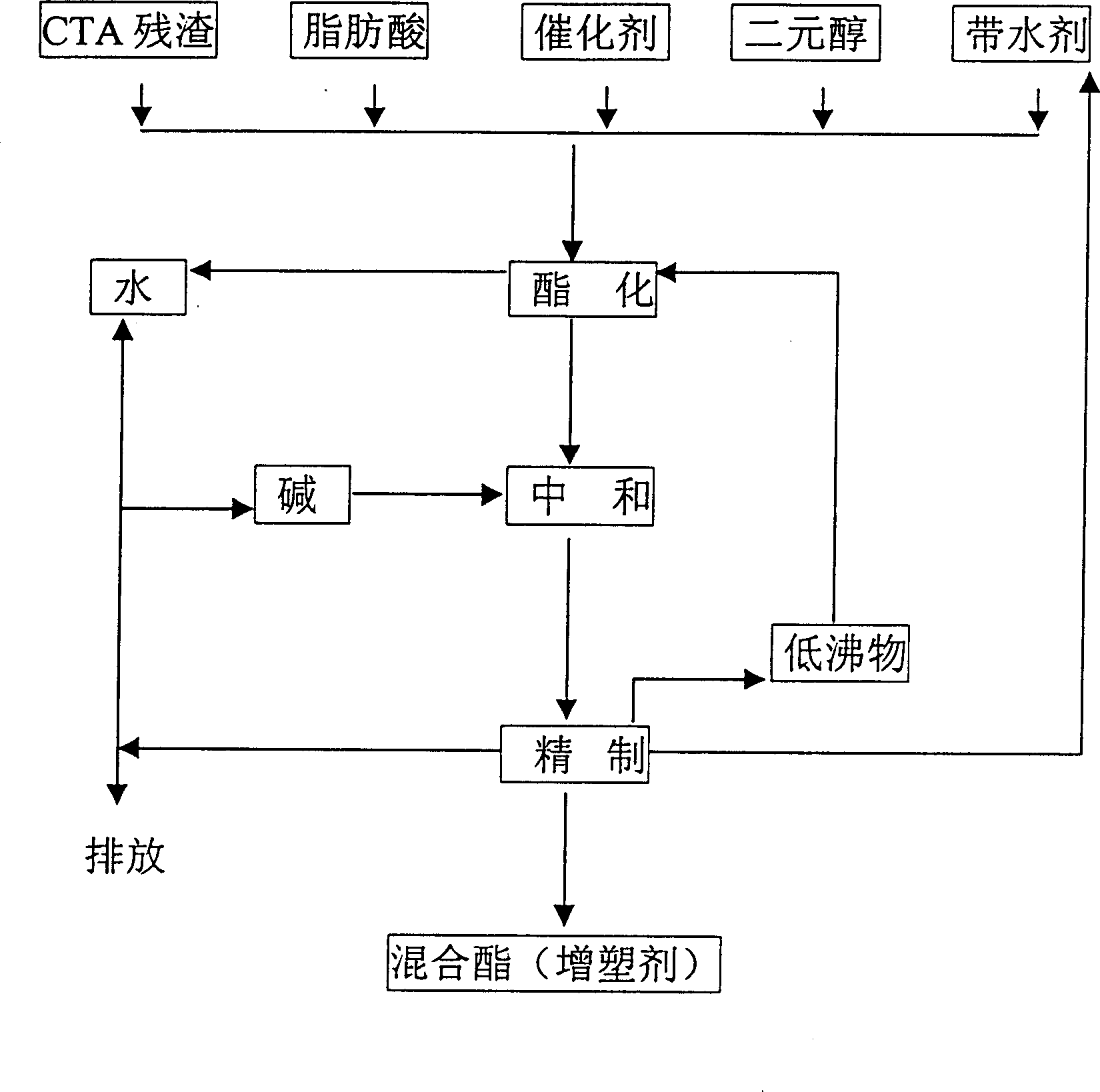

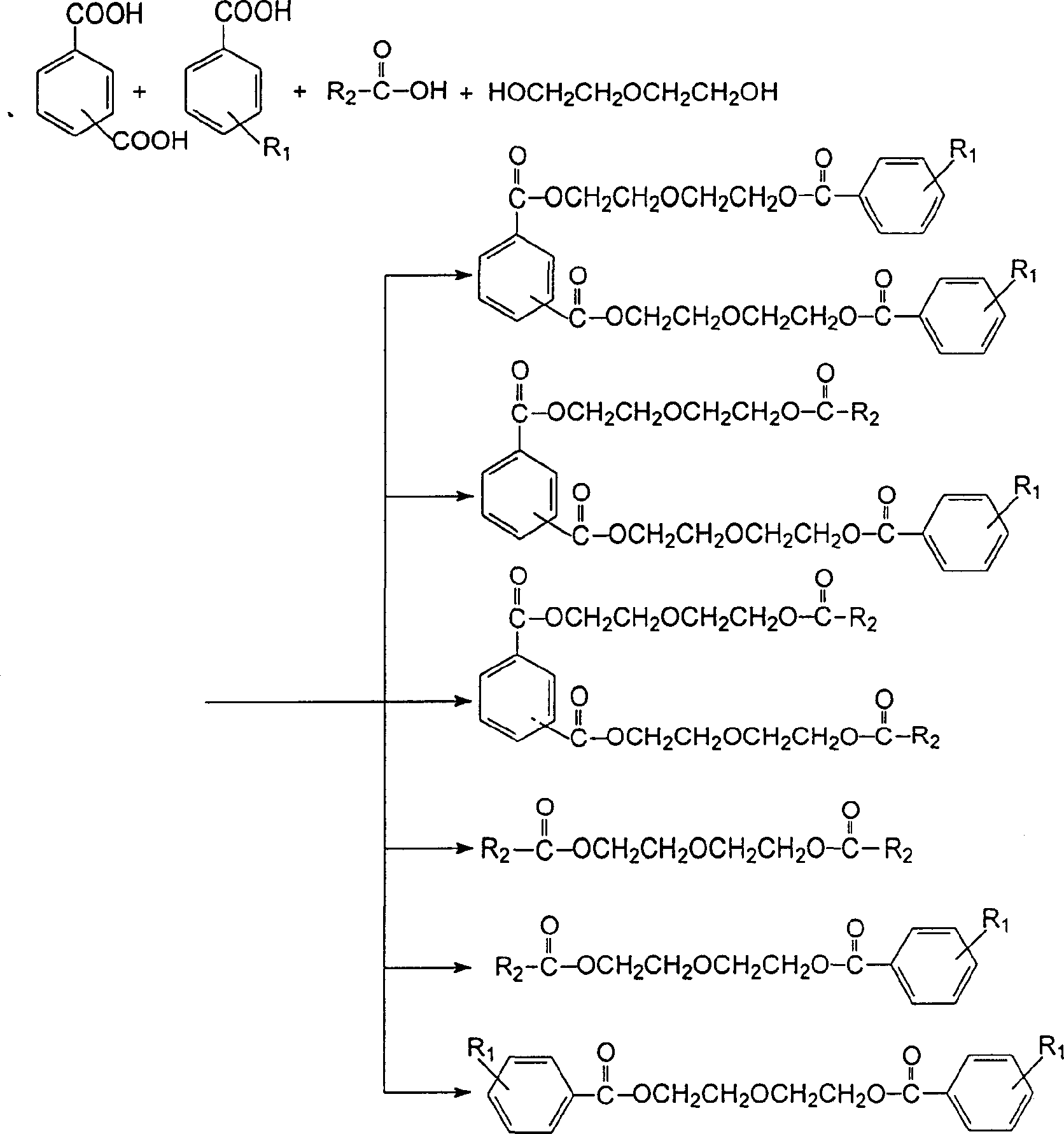

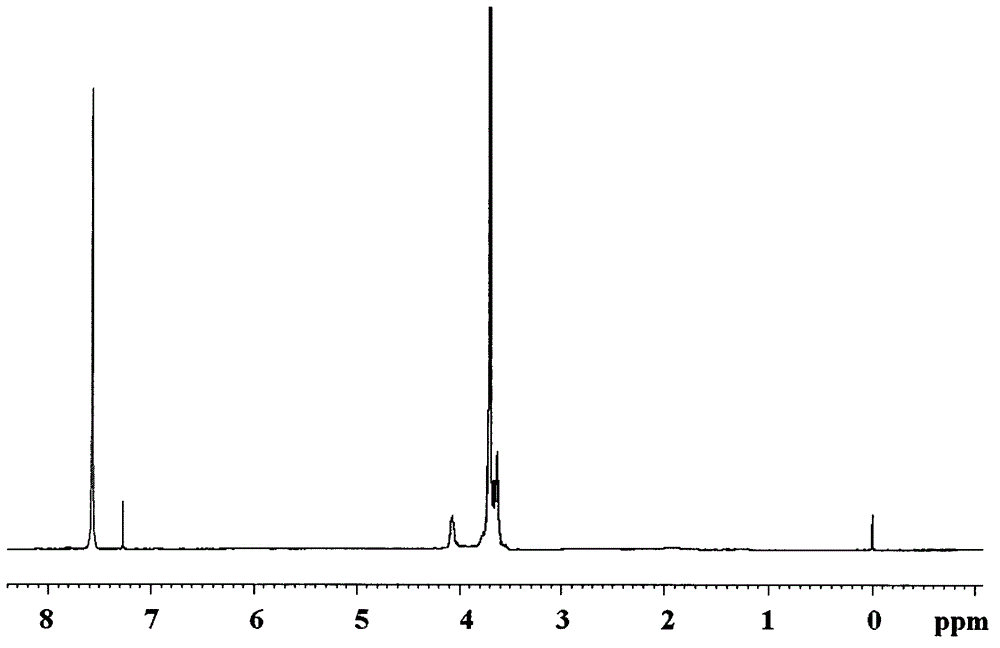

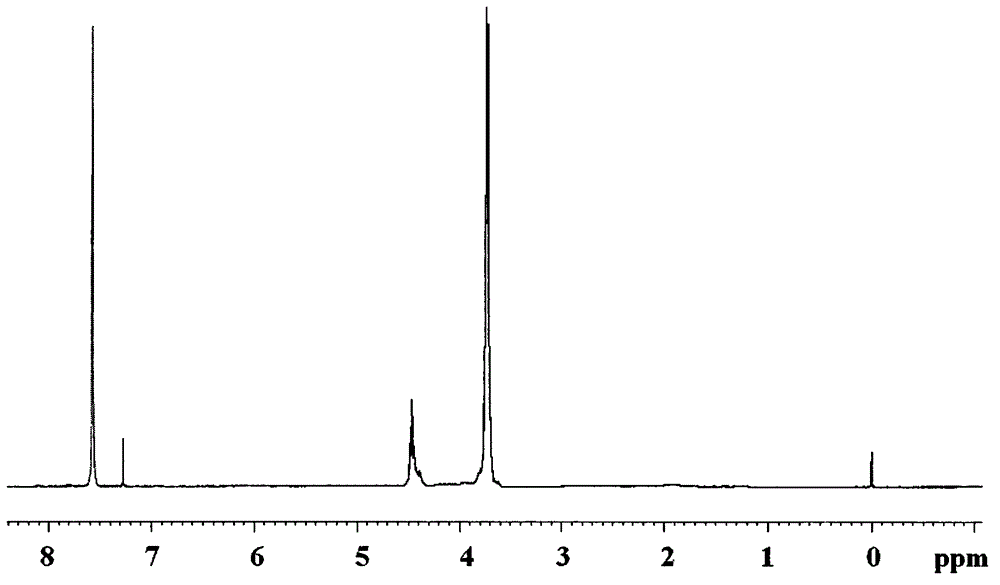

Method for reutilization of residue from crude terephthalic acid product

InactiveCN1521158AHas a plasticizing effectOrganic compound preparationCarboxylic acid esters preparationAlcoholDiol

The present invention is the method of recovering and using coarse terepthalic acid (CTA) residue and the method includes adding fatty acid, dihydric alcohol and catalyst in catalytic amount to catalytically esterify to produce mixed coarse ester, with the molar ratio among residue, fatty acid and dihydric alcohol being 1.0 to 0.2-9.0 to 0.8-5.0. The present invention has the advantages of one-step esterification of CTA residue to obtain mixed ester, short technological process, saving in energy source and low cost, and the outstanding advantage is the comprehensive utilization of CTA residue as industrial resource.

Owner:EAST CHINA UNIV OF SCI & TECH

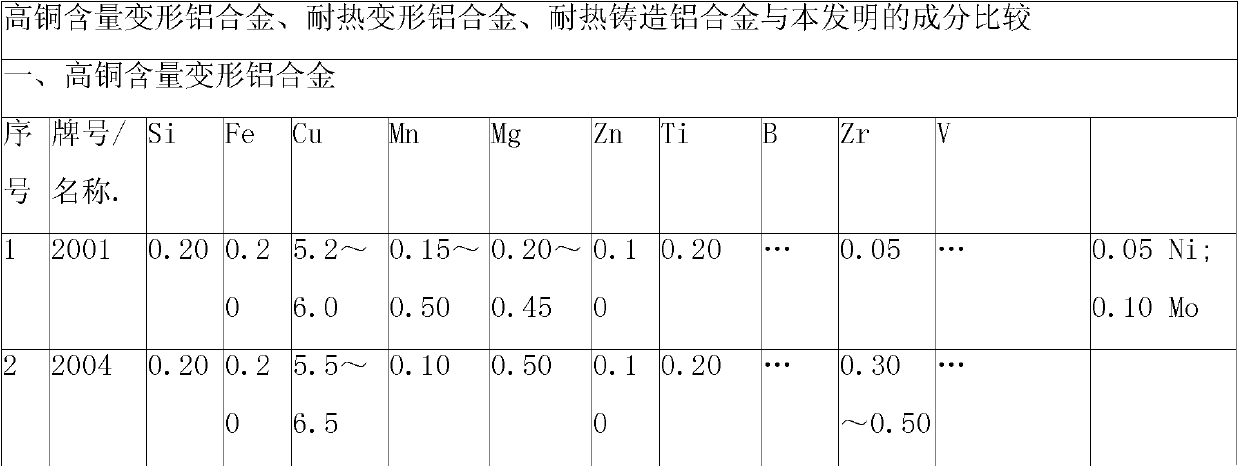

Sc-Ni-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

InactiveCN102021429AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a Sc-Ni-RE high-strength heat-resistant aluminium alloy material and a preparation method thereof. The Sc-Ni-RE high-strength heat-resistant aluminium alloy material comprises the components in percent by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.01-1.0 percent ofNi, 0.01-1.0 percent of Sc, 0.05-5 percent of RE and the balance of Al. With an excellent-quality melt, a solid solution and a phase diagram theory as guidance and through preferably selecting alloy principal elements of Cu, Mn and RE, the invention reduces the alloy quasi solid phase temperature range and solves the problems of large heat cracking tendency, low high-temperature strength of the product, and the like during the casting; and preferably, a multielement microalloying element formula is selected, the material base condition is created for carrying out culturing and grain refining on a high-temperature phase and a strengthening phase in the solid solution, and a high-strength heat-resistant aluminium alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Pharmaceutical formulation

InactiveCN1747720ALower TgHas a plasticizing effectPowder deliveryNervous disorderMedicineBULK ACTIVE INGREDIENT

The present invention provides processes for making and forms of solid dispersions of pharmaceutical active ingredients.

Owner:NOVARTIS AG

Flexible absorbable composite interface screw sheath and preparation method thereof

InactiveCN110051888AImprove ductilityImprove impact toughnessSurgeryBreaking strengthPolymer science

The invention relates to a flexible absorbable composite interface screw sheath and a preparation method thereof. The flexible absorbable composite interface screw sheath is prepared by melt blendingand extrusion granulation of the mixture and injection molding, wherein the mixture mainly comprises a base material and polyethylene glycol, or mainly consists of a matrix material, a polyethylene glycol-flexible polylactone copolymer and beta-TCP, wherein the matrix material is polylactic acid and / or a copolymer thereof, and the flexible polylactone is a polymer of caprolactone and / or valerolactone; the flexible absorbable composite interface screw sheath has elongation at break of not less than 103%, the impact strength of not less than 10 kJ / m<2> and the breaking strength of not less than25 MPa. By adopting the method, the ductility, strength and impact toughness of the absorbable composite interface screw sheath are improved, and the prepared absorbable composite interface screw sheath has high elongation at break, high impact strength and high enough breaking strength, and has good application prospect.

Owner:HANGZHOU REJOIN MASTIN MEDICAL INSTR CO LTD

Toughened PC/PBT/AES alloy material and preparing method thereof

The invention discloses a toughened PC / PBT / AES alloy material. The alloy material comprises the following components, by weight, 30 to 60 parts of polycarbonate, 40 to 70 parts of thermoplastic polyester and 2 to 20 parts of acrylonitrile-EPDM rubber-styrene copolymer. The invention further discloses a preparing method of the toughened PC / PBT / AES alloy material. According to the alloy material and the preparing method, the mobility of PC is remarkably improved, the machining property, the stress cracking resistant property and the chemical resistant property of PC are improved, and cost is reduced. Meanwhile, the defects of PBT caused when PBT is independently used can be overcome, wherein the defects refer to the inclination of buckling deformation in the machining process and the like. A PC / PBT / E-MA-CMA polymer blend has good solvent resistance, abrasive resistance, dimensional stability and stress cracking resistance, the compatibility of the alloy material is obviously improved through E-MA-CMA, a PC / PBT alloy material is obviously toughened due to addition of AES, physical and mechanical properties are good, and shock resistance is greatly improved.

Owner:句容市育达实业投资有限公司

Environment-friendly high-performance chlorohydrin rubber material

InactiveCN104448769AImprove heat resistanceImprove aging resistanceEnvironmental resistanceRubber material

The invention discloses an environment-friendly high-performance chlorohydrin rubber material. The material comprises the following raw materials in parts by weight: 30-70 parts of chlorohydrin rubber, 20-40 parts of chloroprene rubber, 4-6 parts of zinc oxide, 3-5 parts of magnesium oxide, 5-12 parts of lead-free vulcanizing agent XL-21S, 3-9 parts of antimonous oxide, 5-10 parts of decabromodiphenylethane, 5-8 parts of zinc borate, 8-12 parts of tricresyl phosphate, 2-5 parts of acetyl tributyl citrate, 3-6 parts of nano-nylon 6, 5-8 parts of nano-montmorillonite, 40-60 parts of fast extruding furnace black N550, 2-3 parts of paraffin, 2-5 parts of anti-aging agent RD and 1-3 parts of anti-aging agent 4010NA. The environment-friendly high-performance chlorohydrin rubber material is safe and environment-friendly, does not pollute the environment and has excellent heat and aging resistance.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

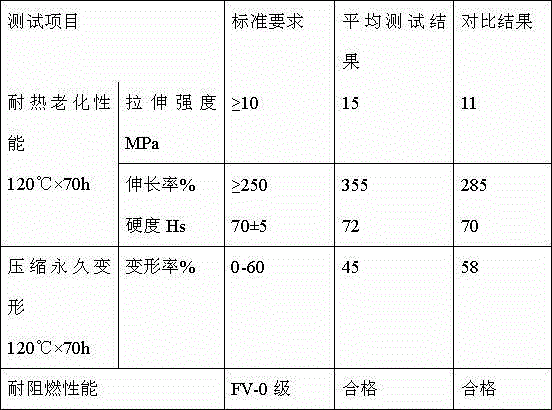

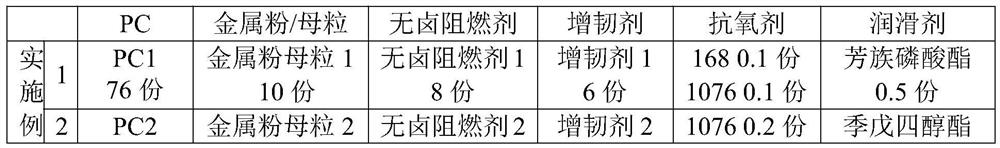

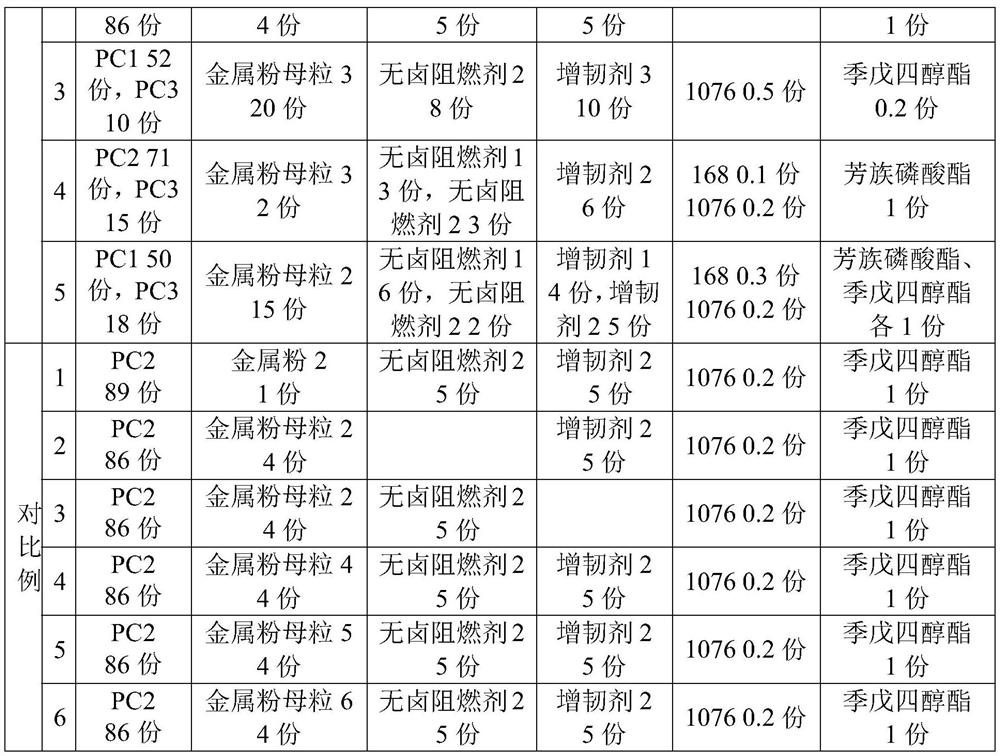

Spraying-free high-flowability high-impact flame-retardant PC material with metal texture and preparation method and application of material

The invention discloses a spraying-free high-flowability high-impact flame-retardant PC material with metal texture as well as a preparation method and application of the material. The material is prepared from 55 to 89 parts of PC resin, 1 to 25 parts of metal powder master batch, 5 to 10 parts of halogen-free flame retardant, 5 to 10 parts of flexibilizer, 0.1 to 0.5 part of antioxidant and 0.2 to 2 parts of lubricant; wherein the metal powder master batch is metal powder subjected to coating treatment by an MAH-St-MMA copolymer. The compatibility between the metal powder and PC is improved through MAH-St-MMA, the material performance and the metal texture are improved, and the technical problem that in the prior art, the flowability, the impact property and the flame retardant property of a metal texture PC material cannot be considered at the same time is solved through cooperative use of high-flowability PC, the metal powder master batch, the flexibilizer and the halogen-free flame retardant; meanwhile, the material has a good appearance effect, high flowability, impact resistance and flame retardance, is easy to form and meets the requirements of wall switches.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

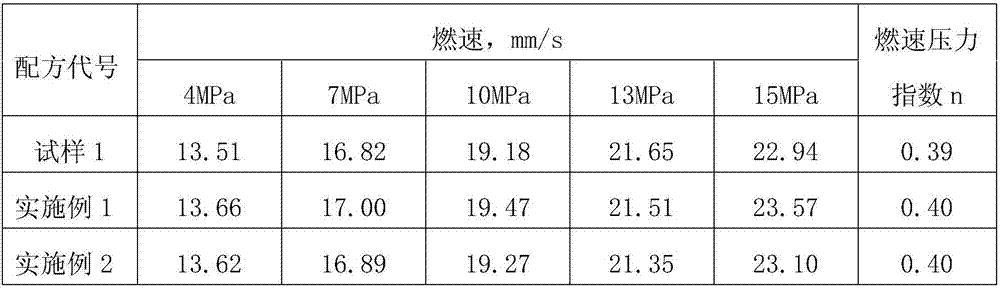

Method for dispersing nano combustion catalyst in composite propellant

ActiveCN107353172AReduce stepsDecentralized operation cycle is shortExplosive working-up apparatusNon-explosive/non-thermic compositionsSolventChemistry

The invention discloses a method for dispersing a nano combustion catalyst in a composite propellant, solving the problems of difficulty in dispersion, multiple steps and complicated process in the prior art. The dispersing method comprises the following steps: ultrasonically dispersing the nano combustion catalyst by utilizing a surfactant and a dispersion medium; adding the uniformly pre-mixed composite propellant into slurry of other components, and mixing, heating in low vacuum degree to remove the solvent in the dispersion medium, and dispersing the nano combustion catalyst in the composite propellant. According to the method disclosed by the invention, and the conventional ultrasonic dispersion and mixed dispersion by a kneading machine are adopted, so that uniform and stable dispersion between the nano combustion catalyst and the composite propellant is realized.

Owner:XIAN MODERN CHEM RES INST

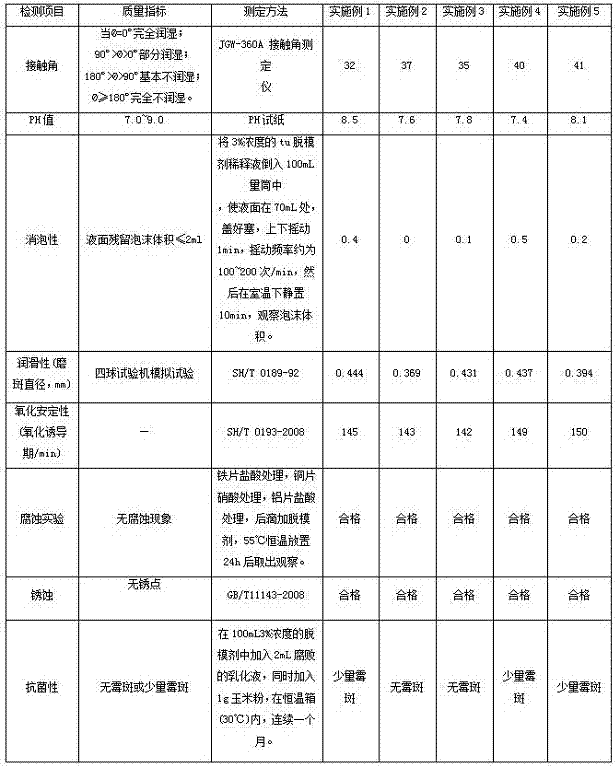

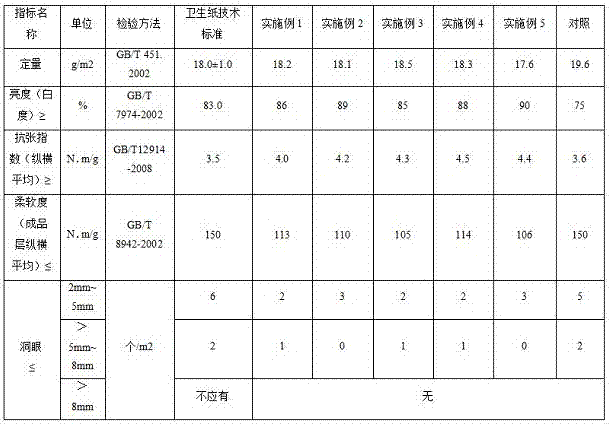

Paper pulp release agent for household paper and preparation method of paper pulp release agent

ActiveCN107447579AImprove the lubrication effectPromote degradationNon-fibrous pulp additionVegetable oilPolyvinyl alcohol

The invention belongs to the technical field of pulping and papermaking processing, and particularly relates to a paper pulp release agent for household paper and a preparation method of the paper pulp release agent. The paper pulp release agent for the household paper is prepared from the following components in parts by mass: 40 to 50 parts of modified vegetable oil, 20 to 30 parts of beewax, 10 to 20 parts of ionic liquid, 10 to 20 parts of plant ash solution, 5 to 10 parts of glycerin monostearate, 3 to 6 parts of polyvinyl alcohol, 2 to 6 parts of polyethyleneimine, 3 to 5 parts of bactericide and 5 to 10 parts of sodium dodecyl sulfate. The release agent prepared by the method can be used for improving the bulk and softness of the household paper, enhancing the smooth and fine feeling of the paper, is relatively high in dry and wet strength and is environmentally friendly.

Owner:NINGXIA RUISHENG MINGJIE INTPROP CONSULTING CO LTD

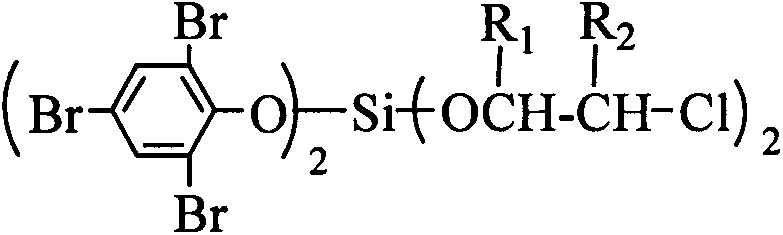

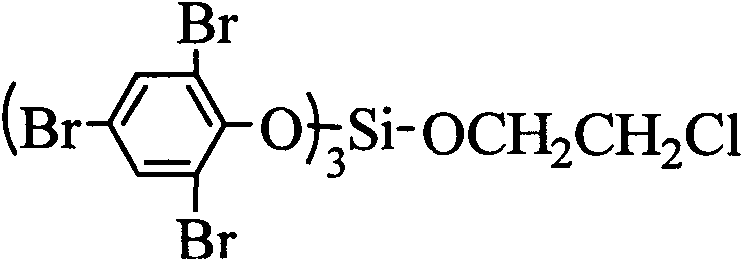

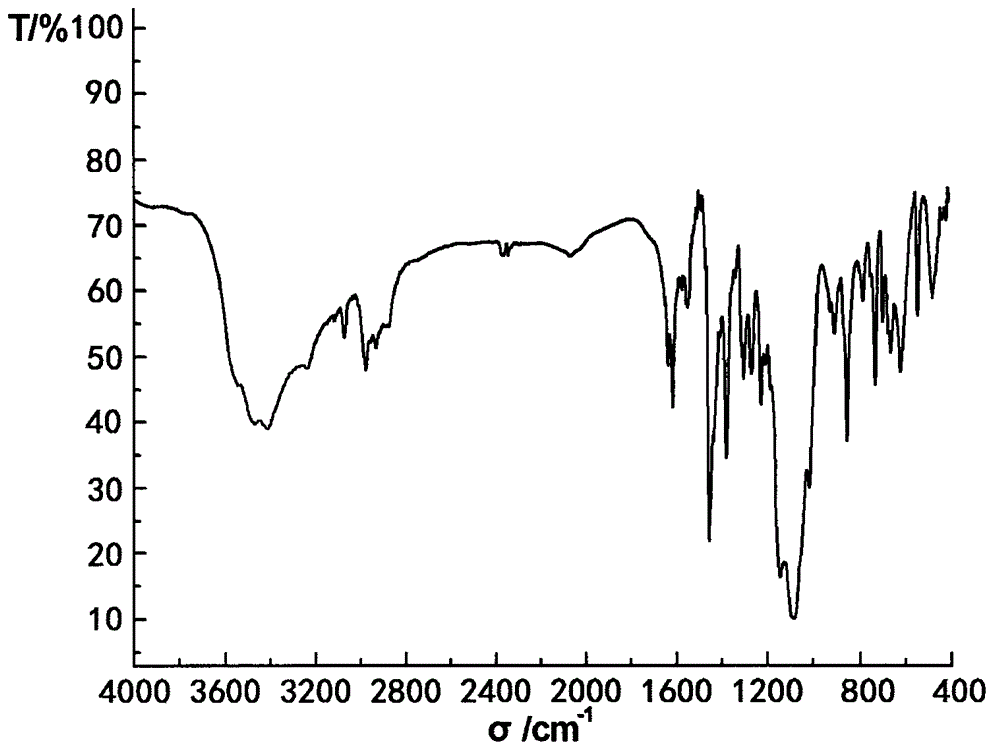

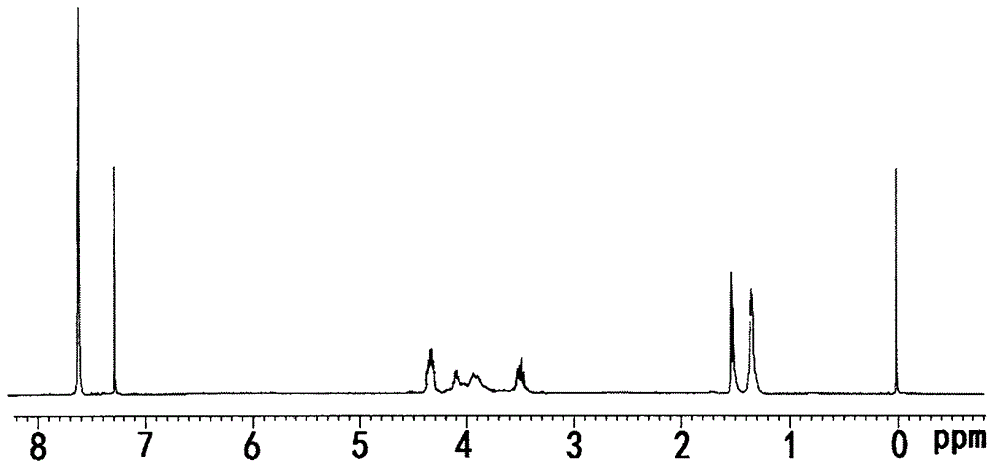

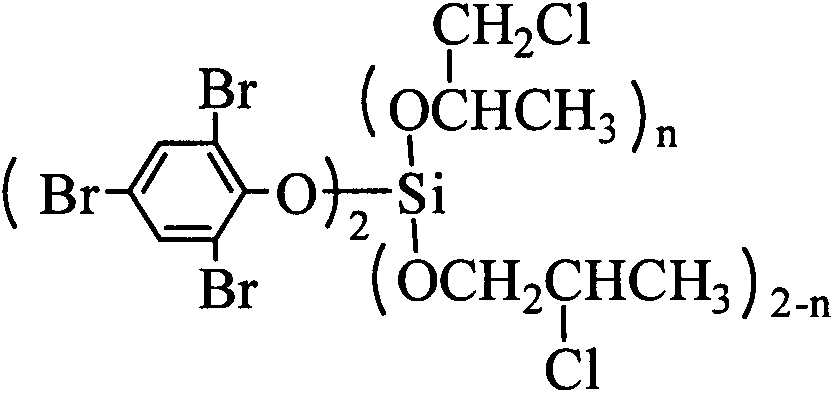

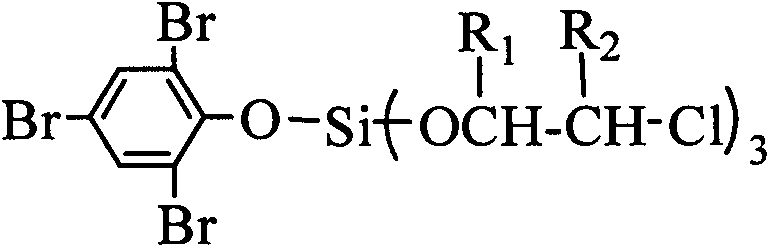

2-(3-broMopropoxy)-2(2-dicholoropropoxy) silane compound used as fire retardant and preparation method thereof

ActiveCN103333189AStable physical and chemical propertiesHigh decomposition temperatureSilicon organic compoundsSolventPlasticizer

The invention relates to a 2-(3-broMopropoxy)-2(2-dicholoropropoxy) silane compound used as a fire retardant and the preparation method thereof. The structural formula of the compound is shown in the specification, wherein when R1equals to H, R2 equals to CH2C1; when R1 equals to CH2C1, R2 equals to H. The preparation method comprises the following steps: dripping dichloropropanol of which the mole is the same as that of silicon tetrachloride into silicon tetrachloride organic solution, reacting for 1 hour at the temperature of 35 DEG C, then adding tribromophenol of which the mole doubles that of silicon tetrachloride, reacting for 4-6 hours at the temperature of 65-90 DEG C, dripping dichloropropanol of which the mole is equal to that of silicon tetrachloride, reacting for 5-7 hours at the temperature of 70-95 DEG C, and reducing pressure and distilling to remove solvent to obtain the 2-(3-broMopropoxy)-2(2-dicholoropropoxy) silane compound. The silane compound is an excellent fire retardant plasticizer, has carbon-forming and anti-dripping functions, can be used as fire retardant made of polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like, and is easy to access in raw material, low in production cost, small in equipment investment, simple in production technology, and easy for large-scale production.

Owner:张家港市乐余科创园投资发展有限公司

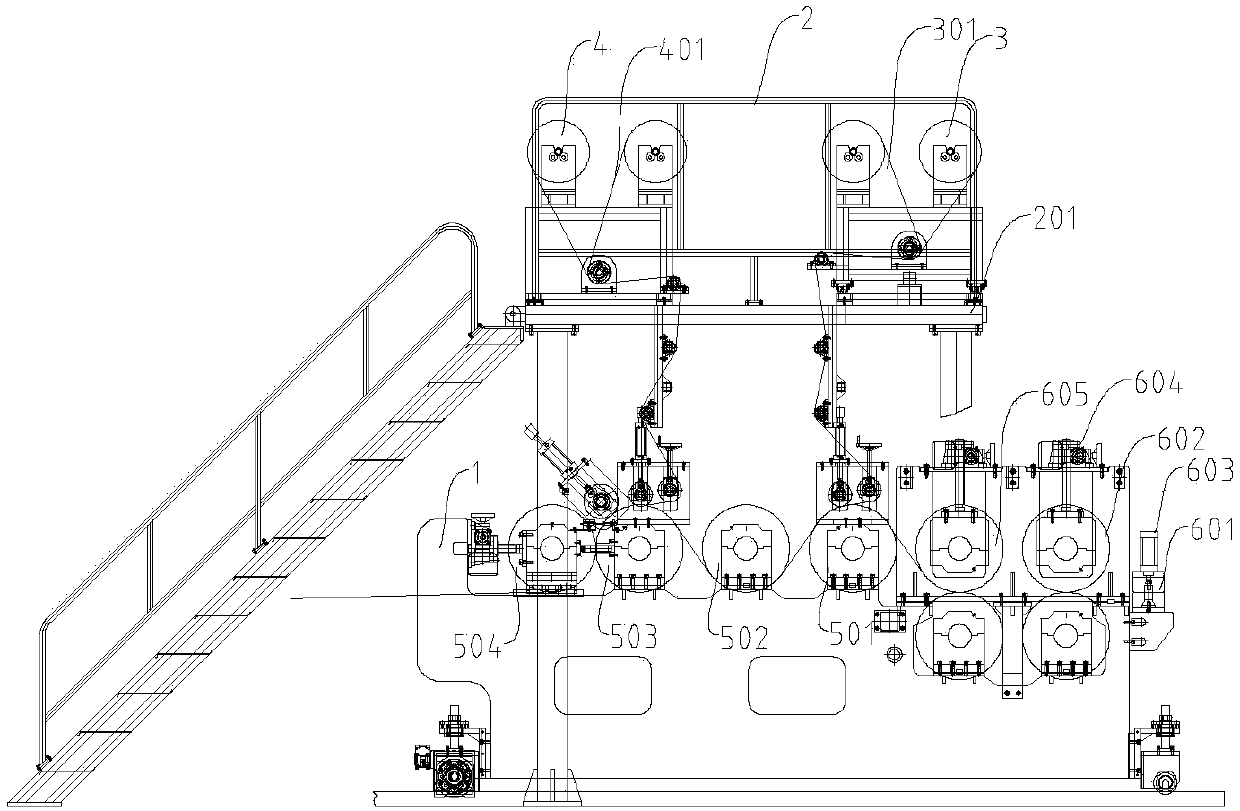

Floor production method

InactiveCN107650482AGuaranteed stereotypesAvoid curlLaminationLamination apparatusMetallurgyMethods of production

A board production method includes: mixing materials, performing melt extrusion, coating an extruded blank, cooling and cutting. The coating is characterized by including the steps of firstly, performing first-stage heating and compacting on the extruded blank, and coating the surface on one side of the extruded blank with a first layer of film in the process of the first-stage heating and compacting; secondly, performing at least one second-stage heating and compacting on the extruded blank after the first compacting; thirdly, performing third-stage heating and compacting on the heated extruded blank, and coating the surface of the first layer of film with a second layer of film in the process of the third-stage heating and compacting. The method has the advantages that the second-stage heating and compacting is performed on the blank coated with the first layer of film, the fitting degree of the first layer of film and the blank is increased, a plasticizing effect on the first layerof film is achieved at the same time, then the second layer of film is coated, and the fitting degree of the second layer of film and the blank can be also increased.

Owner:QINGDAO SANYI PLASTIC MACHINERY

Wearing-resistant fire-resistant coating for air compressor and preparation method of coating

InactiveCN107227099AGood self-extinguishingImprove heat resistanceFireproof paintsAnti-corrosive paintsEpoxyWear resistant

The invention discloses a wearing-resistant fire-resistant coating for an air compressor and belongs to the technical field of coatings. The coating comprises the following raw materials in parts by weight: 36-40 parts of a brominated epoxy resin, 18-24 parts of polyvinylidene fluoride, 10-12 parts of aluminum silicate, 5-7 parts of emery powder, 3-5 parts of cast stone powder, 6-7 parts of zinc oxide, 2-5 parts of expanded perlite, 6-8 parts of m-dihydroxybenzene (diphenyl phosphate), 5-7 parts of melamine phosphate, 9-11 parts of triethyl citrate, 3-5 parts of sodium silicate, 0.5-1 part of carboxymethylcellulose, 1-3 parts of a defoaming agent, 0.2-0.8 part of an anti-electrostatic agent, 4-6 parts of a coupling agent, 14-18 parts of methanol and 17-20 parts of water. The invention further discloses a preparation method of the wearing-resistant fire-resistant coating for the air compressor. The coating is relatively high in wearing resistance and fireproof effect, high in corrosion resistance and long in service life.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

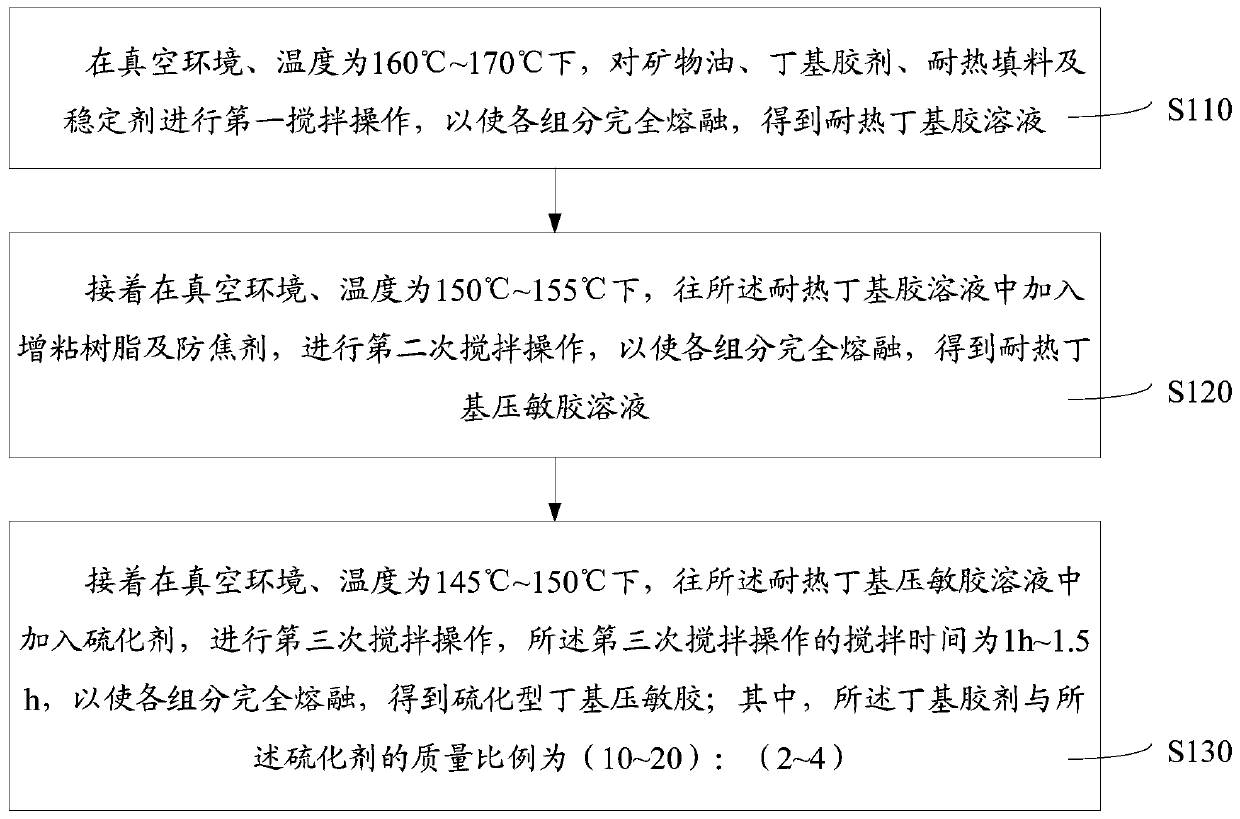

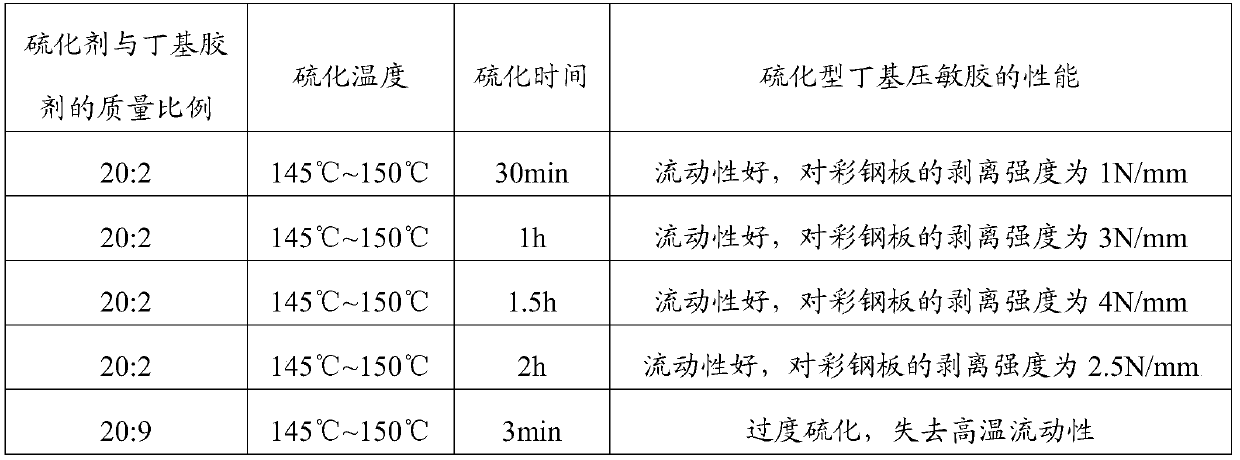

Vulcanized butyl pressure-sensitive adhesive

ActiveCN110184003AImprove heat resistanceImprove cohesive energyNon-macromolecular adhesive additivesOil/fat/wax adhesivesHeat resistanceButyl rubber

The invention relates to the field of butyl rubber pressure-sensitive adhesive, and discloses vulcanized butyl pressure-sensitive adhesive. The vulcanized butyl pressure-sensitive adhesive is preparedfrom the following components in parts by mass: 30-40 parts of mineral oil, 10-20 parts of butyl glue, 20-40 parts of heat-resistant filler, 2-4 parts of a vulcanizing agent, 0.1-0.4 part of a scorchretarder, 1-5 parts of a stabilizer and 20-30 parts of tackifying resin, wherein the heat-resistant filler can improve the heat resistance of the vulcanized butyl pressure-sensitive adhesive to a large extent; the vulcanizing agent is used for improving the cohesive energy and the ability of wrapping the heat-resistant filler of butyl rubber, so that the butyl rubber can accommodate more heat-resistant filler, thereby improving the cohesive energy and heat resistance of the vulcanized butyl pressure-sensitive adhesive, and overcoming the shortcomings existing in common butyl rubber pressure-sensitive adhesive that the cohesive energy is low, cold flow phenomenon is serious and the heat resistance is poor.

Owner:HUIZHOU NENGHUI CHEM CO LTD

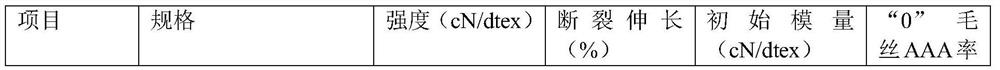

Manufacturing method of polyamide 56 industrial yarn for airbags

ActiveCN111826737ADoes not affect orientationThe polymerization process is simpleArtificial filament heat treatmentTextile/flexible product manufactureYarnSpinning

The invention relates to the field of polyamide fibers, and discloses a manufacturing method of polyamide 56 industrial yarn for airbags. The manufacturing method comprises the steps of a salifying stage, a polymerizing stage, a spinning stage, a drafting stage and the like. According to the manufacturing method, a nucleating agent is added, and therefore the grain size of polyamide 56 can be reduced; orientation and crystallization are conducted in sequence through the saturated water vapor bath drafting working procedure, the hot roller drafting working procedure and the like, the grain sizeof the polyamide 56 is controlled through a heat setting technology, polyamide 56 fibers with the high orientation and the low grain size are obtained, and therefore the polyamide 56 industrial yarnwith the high strength and the low modulus is finally obtained. The obtained product can be widely applied to the field of airbags, and the storage performance and the flexibility of the airbags can be improved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Environment-friendly epichlorohydrin rubber material resistant to wear, heat and ageing

InactiveCN104448770APlay a flame retardant effectEnvironmental performanceRubber materialEnvironmental resistance

The invention discloses an environment-friendly epichlorohydrin rubber material resistant to wear, heat and ageing. The epichlorohydrin rubber material is prepared from the following raw materials in parts by weight: 30-70 parts of epichlorohydrin rubber, 20-40 parts of powdered acrylonitrile-butadiene rubber, 1-4 parts of gamma-(2,3-epoxyropoxy)propyltrimethoxysilane, 4-6 parts of zinc oxide, 3-5 parts of stearic acid, 5-12 parts of sulfur, 3-9 parts of lauryl mercaptan, 5-10 parts of decabromodiphenyl ethane, 5-8 parts of zinc borate, 8-12 parts of tricresyl phosphate, 2-5 parts of tributyl acetylcitrate, 3-6 parts of nano aluminum nitride, 5-8 parts of nano kaolin, 40-60 parts of fast extruding furnace black N550, 2-3 parts of paraffin, 2-5 parts of anti-ageing agent RD and 1-3 parts of anti-ageing agent TPPD. The environment-friendly epichlorohydrin rubber material resistant to wear, heat and ageing is safe and environment-friendly, and excellent in wear resistance, heat resistance and ageing resistance.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

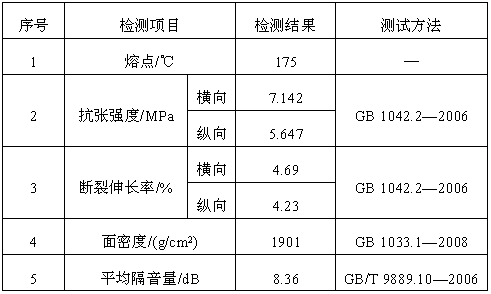

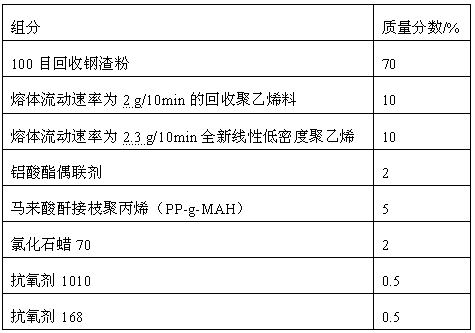

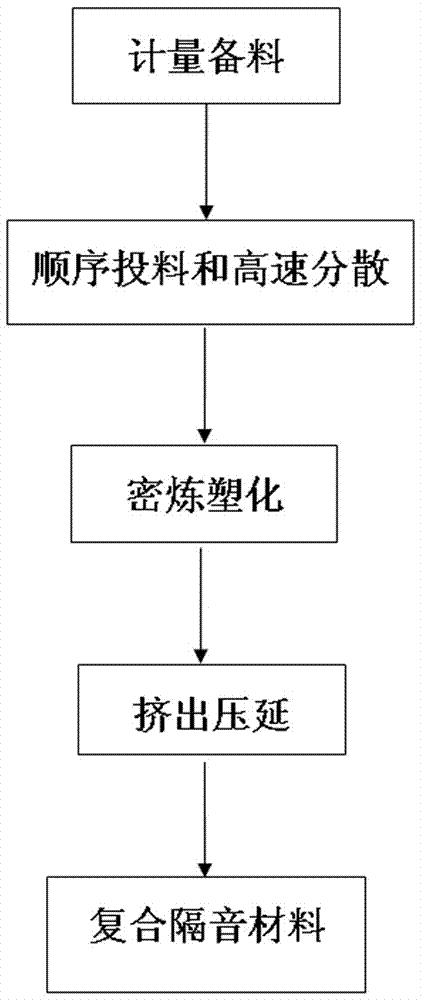

A kind of composite sound insulation material and preparation method thereof

Owner:KUNMING IRON & STEEL HLDG CO LTD

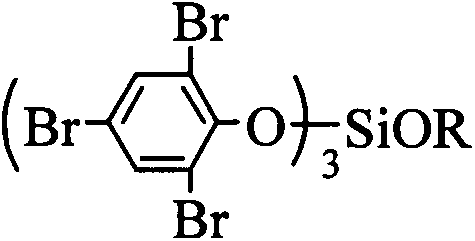

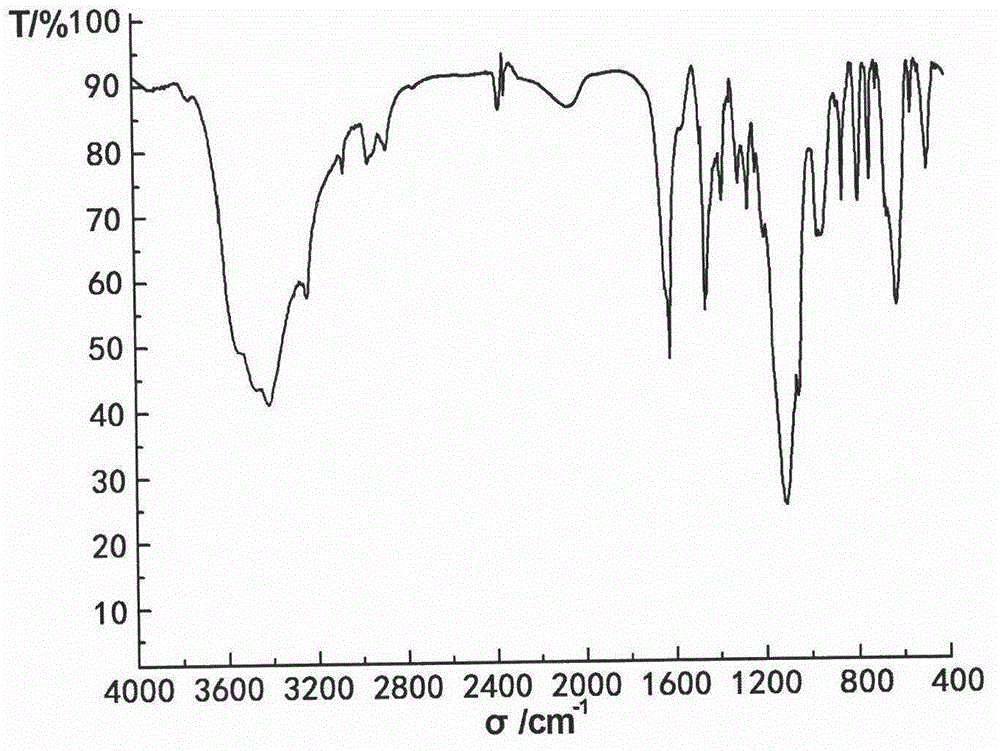

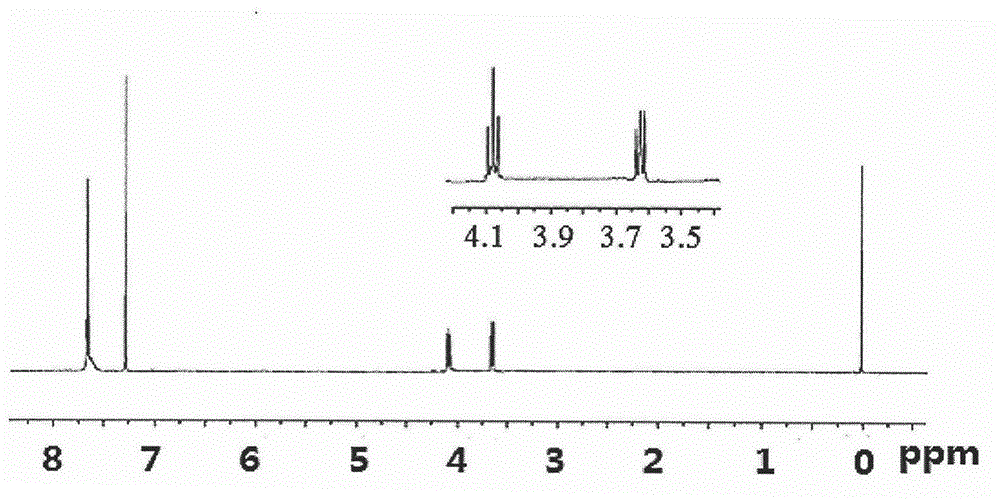

Flame retardant tri-(tribromophenoxy) halogen propoxy silane compound and preparation method thereof

ActiveCN103333192AStable physical and chemical propertiesHigh decomposition temperatureSilicon organic compoundsSolventBromine

The invention relates to a flame retardant tri-(tribromophenoxy) halogen propoxy silane compound and a preparation method thereof. A structural formula of the compound is as follows as shown in the specification, wherein R is 2-chlorine-1-propyl, 1-chlorine-2-propyl, 3-chlorine-1-propyl, 2-bromine-1-propyl, 1-bromine-2-propyl or 3-bromine-1-propyl. The preparation method comprises the steps that equimolar halogenated propyl alcohol is dropwise added to an organic solution of silicon tetrachloride, and reacts at 30 DEG C for 1h; three times of mole of tribromphenol is added, and reacts at 70-100 DEG C for 6-9h; a solvent is removed by reduced pressure distillation; and tri-(tribromophenoxy) halogen propoxy silane is obtained. Tri-(tribromophenoxy) halogen propoxy silane is good in flame retardancy and plasticity, has charring and dripping prevention functions, has good compatibility with a high polymer material, can serve as a flame retardant of polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like, raw materials of tri-(tribromophenoxy) halogen propoxy silane are easy to obtain, the production cost is low, the equipment investment is low, a production technology is simple, and the scale production is facilitated.

Owner:张家港市乐余科创园投资发展有限公司

Silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound used as fire retardant and preparation method thereof

ActiveCN103333194APhysicochemically stableHigh decomposition temperatureSilicon organic compoundsEpoxyPolymer science

The invention relates to a silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound used as a fire retardant and the preparation method thereof. The structural formula of the compound is shown in the specification. The preparation method comprises the following steps: filling ethylene oxide of which the mole is same as that of silicon tetrachloride in silicon tetrachloride organic solution at the temperature of below 20 DEG C, adding tribromophenol of which is three times the mole of silicon tetrachloride, carrying out the thermal reaction for 6-10 hours at the temperature of 100-120 DEG C, and reducing pressure and distilling to remove solvent and a small amount of low boiling point substances to obtain the silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound. The silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound is an excellent fire retardant plasticizer, has carbon-forming and anti-dripping functions and good compatibility with high polymer material, can be used as fire retardants made of polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like, and is easy to access in raw material, low in production cost, small in equipment investment, simple in production technology, and easy for large-scale production.

Owner:张家港市乐余科创园投资发展有限公司

Flame retardant silicic acid di-(tribromophenyl) dichlorohydrin compound and preparation method thereof

ActiveCN103333193APhysicochemically stableHigh decomposition temperatureSilicon organic compoundsEpoxyPolymer science

The invention relates to a flame retardant silicic acid di-(tribromophenyl) dichlorohydrin compound and a preparation method thereof. A structural formula of the compound is shown in the specification, wherein n is an integer between 0 and 2. The preparation method comprises the steps that equimolar epoxy propane is dropwise added to an organic solution of silicon tetrachloride, and reacts at 30 DEG C for 30min; twice mole of tribromophenol is added, and reacts at 70-100 DEG C for 3-6h; epoxy propane at a certain mole ratio is dropwise added, and reacts at 60-85 DEG C for 4-6h; a solvent and a low-boiling-point object are removed by reduced pressure distillation; and silicic acid di-(tribromophenyl) dichlorohydrin is obtained. Silicic acid di-(tribromophenyl) dichlorohydrin is an excellent antiflaming plasticizer, has charring and dripping prevention functions, has good compatibility with a high polymer material, and can serve as a flame retardant of polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like, raw materials of silicic acid di-(tribromophenyl) dichlorohydrin are low in cost and easy to obtain, the production cost is low, the equipment investment is low, a production technology is simple, and the scale production is facilitated.

Owner:张家港市乐余科创园投资发展有限公司

Modified starch-based adhesive for high-speed cigarette making machine

ActiveCN104946163AEasy to dryImprove adhesionAmylose/amylopectin adhesivesAmylose/amylopective derivative adhesivesAdhesivePreservative

The invention relates to a modified starch-based adhesive for a high-speed cigarette making machine. The modified starch-based adhesive comprises, by weight, 10%-80% of urea modification waxiness corn starch and / or a derivative of the urea modification waxiness corn starch, 10%-80% of degraded waxiness corn starch and / or a derivative of the degraded waxiness corn starch, 2%-20% of modified tamarindus powder and a corrosion remover.

Owner:钟博文

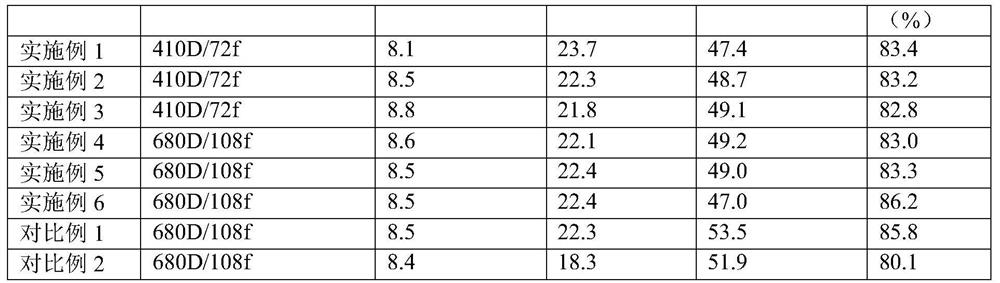

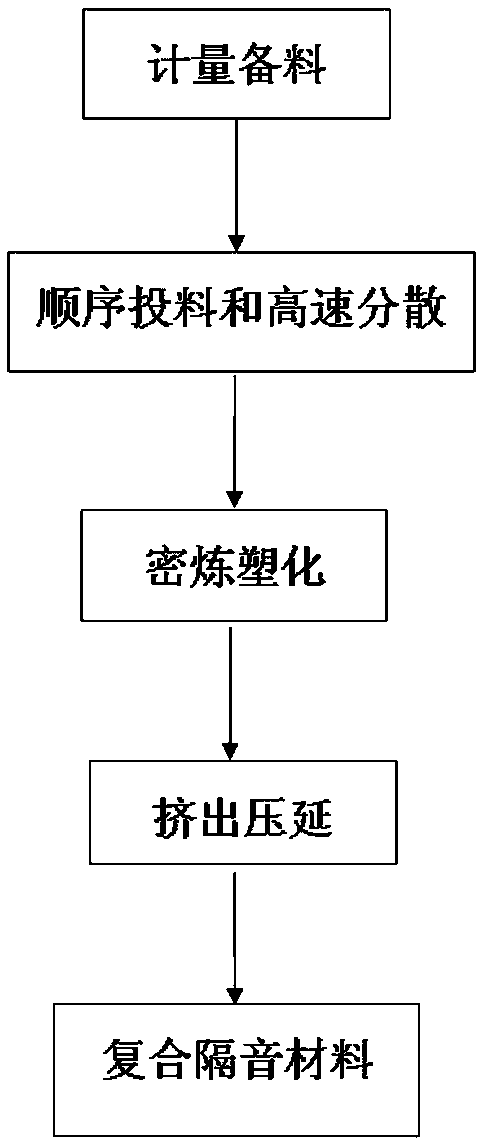

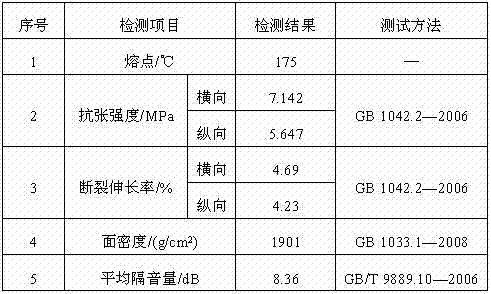

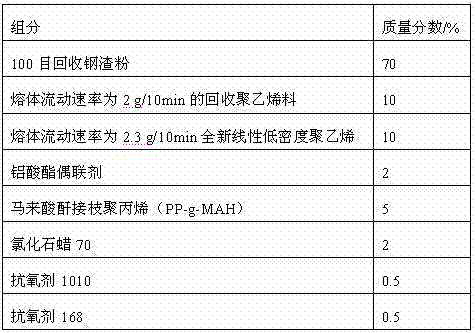

Composite sound-insulation material and preparation method thereof

The invention discloses a composite sound-insulation material and a preparation method thereof. The composite sound-insulation material is composed of the following components in percentage by mass: 65-75% of reclaimed steel slag powder, 10-20% of reclaimed polyethylene, 5-10% of linear low-density polyethylene, 2.5-5% of high-polymer compatilizer, 1-2% of diluter, 1-2% of coupling agent and 0.5-1% of antioxidant. The preparation method comprises the following steps: metering and preparing materials, sequentially adding the materials, dispersing at high speed, banburying, plastifying, extruding, calendering and the like. The steel scrap slag and waste plastic are recycled, thereby implementing reutilization of the waste resources. The composite sound-insulation material has the advantages of low cost, high constructability and the like, is easy for secondary processing and applicable to sound insulation treatment of irregular objects.

Owner:KUNMING IRON & STEEL HLDG CO LTD

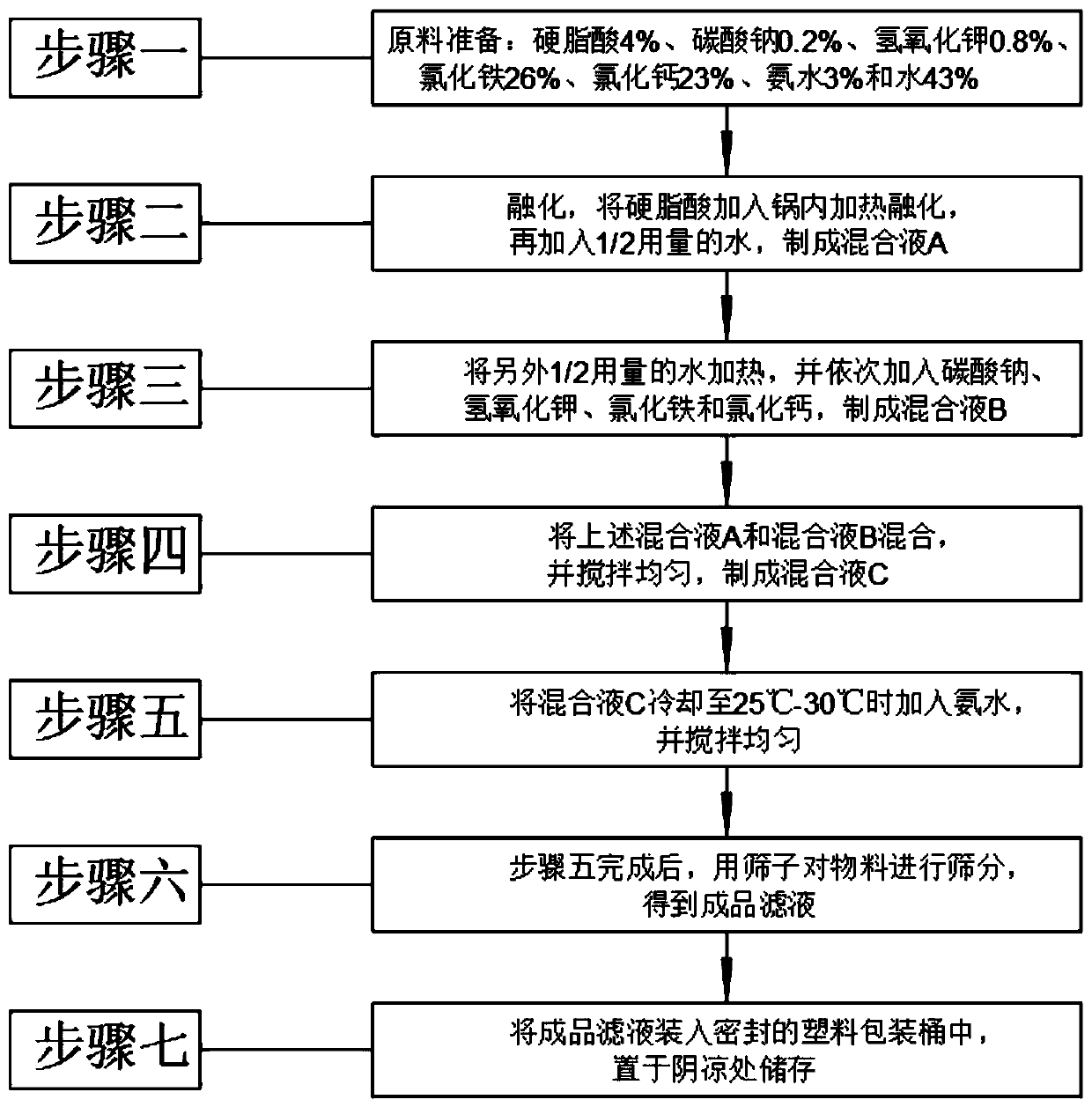

Waterproofing agent with long-lasting water resistance for walls and processing technology of waterproofing agent

InactiveCN110423036AImprove waterproof performanceLong waterproof lifePotassium hydroxideStearic acid

The invention discloses a waterproofing agent with long-lasting water resistance for walls. The waterproofing agent comprises the following components, in percentages by weight: 3%-5% of stearic acid,0.1%-0.3% of sodium carbonate, 0.7%-0.9% of potassium hydroxide, 25%-27% of ferric chloride, 22%-24% of calcium chloride, 2%-4% of ammonia water and 42%-44% of water. A processing technology comprises the following steps: preparing the raw materials, melting the raw materials, performing primary mixing on the raw materials, performing secondary mixing on the raw materials, and performing sievingto obtain the finished-product filtrate. According to the waterproofing agent for the walls provided by the invention, the stearic acid is added, so that the waterproofing agent has the advantages ofgood water resistance, long waterproof service life, low process difficulty and low costs; the alkali metal compound sodium carbonate is added, the compound has a plasticizing effect, so that a water-ash ratio can be reduced, water seepage channels can be cut off and reduced, compactness of mortar can be increased, and the mortar has a waterproof property; and the ferric chloride is added, oxidized iron sheets and powder are used as main raw materials, and the ferric chloride waterproofing agent has the functions of strengthening and early strengthening, can continuously improve the compressive strength of concrete and has relatively high impermeability in the early stage.

Owner:YANGZHOU POLYTECHNIC INST

Method for reutilization of residue from crude terephthalic acid product

InactiveCN1249013CHas a plasticizing effectOrganic compound preparationCarboxylic acid esters preparationAlcoholDiol

The present invention is the method of recovering and using coarse terepthalic acid (CTA) residue and the method includes adding fatty acid, dihydric alcohol and catalyst in catalytic amount to catalytically esterify to produce mixed coarse ester, with the molar ratio among residue, fatty acid and dihydric alcohol being 1.0 to 0.2-9.0 to 0.8-5.0. The present invention has the advantages of one-step esterification of CTA residue to obtain mixed ester, short technological process, saving in energy source and low cost, and the outstanding advantage is the comprehensive utilization of CTA residue as industrial resource.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of flame retardant tribromophenoxy tris (dichloropropoxy) silane compound and preparation method thereof

ActiveCN103319516BPhysicochemically stableHigh decomposition temperatureSilicon organic compoundsPolyesterEpoxy

The invention relates to a fire retardant tribromophenoxy tri(dichloro propanolato)silane compound and its preparation method. The structure of the compound is as shown in the formula in the specification, wherein R2=CH2Cl when R1=H; and R2=H when R1=CH2Cl. The preparation method comprises the following steps: dropwisely adding equimolar dichlorohydrin into a silicon tetrachloride organic solution to react at 35 DEG C for 1h, adding equimolar tribromophenol to react at 50-80 DEG C for 2-5h, dropwisely adding double mole times of dichlorohydrin to react at 50-70 DEG C for 3-6h, and carrying out underpressure distillation to remove a solvent so as to obtain a product tribromophenoxy tri(dichloro propanolato)silane. The product is an excellent flame retardation plasticizer, has charcoal-forming and antidrip effects, and can be used as a fire retardant of materials such as polyvinyl chloride, nonsaturated polyester, polyurethane and epoxy resin, etc. Raw materials of the product are cheap and easily available. Production costs are low. Equipment investment is little. The production technology is simple. The preparation method is easy for large-scale production.

Owner:张家港市乐余科创园投资发展有限公司

Electrophoretic paint based on acrylic acid resin as well as processing process thereof

InactiveCN110079174AImproved shape stabilityImprove integrityAnti-corrosive paintsPaints for electrolytic applicationsElectrophoresisLead oxide

The invention relates to the technical field of paint processing, and discloses electrophoretic paint based on acrylic acid resin as well as a processing process thereof. The electrophoretic paint based on the acrylic acid resin comprises the following components: 35 to 50 parts of acrylic acid resin, 10 to 15 parts of amino resin, 5 to 8 parts of ethyl cellulose, 3 to 5 parts of dibutyl phthalate, 2 to 4 parts of polycaprolactone diol, 1 to 2 parts of lead oxide, 4 to 6 parts of trimethylolpropane and 3 to 5 parts of a crosslinking agent. The acid and alkali resistance of workpieces can be improved.

Owner:枣阳市旺前电泳涂料有限公司

A toughened modified polylactic acid-polybutylene adipate terephthalate composite material and a preparing method thereof

InactiveCN109111708ALower glass transition temperatureHigh heat distortion temperaturePolybutyleneThermal deformation

A toughened modified polylactic acid-polybutylene adipate terephthalate composite material and a preparing method thereof is disclosed. The composite material includes, by weight, 80-90 parts of polylactic acid, 20-30 parts of polybutylene adipate terephthalate, 10-15 parts of triethyl citrate, 6-10 parts of vegetable oil polyol, 7-10 parts of talc powder and 7-10 parts of diatomite. In the composite material, the triethyl citrate and the vegetable oil polyol are synergistic, can improve the degree of dispersion of the dispersion phase and can improve toughness; the triethyl citrate itself hasa plasticization function, can reduce the glass transition temperature of the composite material, and is low in molecular weight so that the enzyme degradation rate can be increased; the talc powderand the diatomite, as fillers, reduce the manufacturing cost, and are synergistic with the vegetable oil polyol to play a role of a nucleating agent, thus increasing the glass transition temperature of glass and improving thermal deformation temperature of the material.

Owner:河南龙都天仁生物材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com