A toughened modified polylactic acid-polybutylene adipate terephthalate composite material and a preparing method thereof

A technology of butylene terephthalate and polyadipic acid, which is applied in the field of biodegradable composite materials, can solve the problems affecting the biodegradability of composite materials, affecting the toughness and other mechanical characteristics, the degree of biodegradability, and the price of polylactic acid. Increase the problems such as increase the glass transition temperature, reduce the glass transition temperature, and improve the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

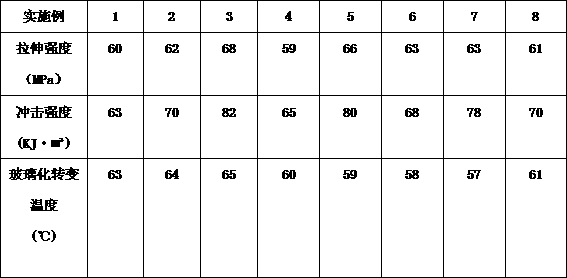

Examples

Embodiment 1

[0018] The ratio of each component is 80 parts of polylactic acid, 20 parts of polybutylene adipate terephthalate, 10 parts of triethyl citrate, 6 parts of vegetable oil polyol, 7 parts of talc and 7 parts of diatomaceous earth, Wherein vegetable oil polyol adopts corn oil polyol.

Embodiment 2

[0020] The ratio of each component is 90 parts of polylactic acid, 30 parts of polybutylene adipate terephthalate, 15 parts of triethyl citrate, 10 parts of vegetable oil polyol, 10 parts of talc and 10 parts of diatomaceous earth, Wherein vegetable oil polyol adopts pine nut oil polyol.

Embodiment 3

[0022] The ratio of each component is 85 parts of polylactic acid, 25 parts of polybutylene adipate terephthalate, 13 parts of triethyl citrate, 8 parts of vegetable oil polyol, 8 parts of talc and 8 parts of diatomaceous earth, Wherein vegetable oil polyol adopts castor oil polyol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com