Paper pulp release agent for household paper and preparation method of paper pulp release agent

A technology of household paper and release agent, which is applied in the field of pulping and papermaking processing, can solve the problems of less application, achieve high melting point, improve retention rate, and prevent fiber flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

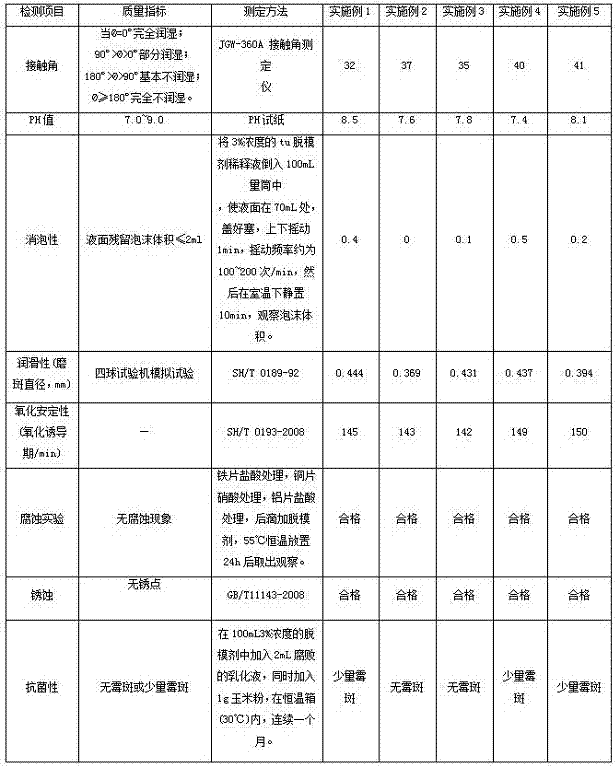

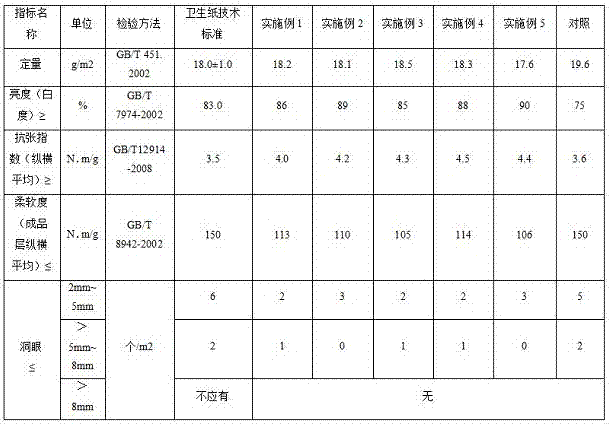

Examples

Embodiment 1

[0022] Vegetable oil pre-modification: put 80 parts of vegetable oil into the reaction kettle, add 20 parts of acetic acid solution and 2 parts of strong acid cationic resin catalyst, raise the temperature, and slowly add 43 parts of 30% hydrogen peroxide dropwise at the same time, after the dropwise addition of hydrogen peroxide, keep The temperature was reacted at 60°C for 5.5h, then washed with hot sodium carbonate solution, and then washed with saturated brine until neutral, evaporated to remove water, and then added 70 parts of potassium hydroxide ethanol solution in the reaction kettle, at a temperature of 75°C React for 30 minutes to obtain modified vegetable oil;

[0023] Mixing reaction: Add 30 parts of beeswax into the container and heat to 75°C to melt, then add 48 parts of modified vegetable oil, 18 parts of ionic liquid, 5 parts of glyceryl stearate, 4 parts of polyvinyl alcohol, 4 parts of polyethyleneimine, 4 parts of fungicide, 5 parts of sodium dodecyl sulfona...

Embodiment 2

[0025] Vegetable oil pre-modification: put 70 parts of vegetable oil into the reaction kettle, add 21 parts of acetic acid solution and 4 parts of strong acid cationic resin catalyst, raise the temperature, and slowly add 45 parts of 30% hydrogen peroxide dropwise, after the hydrogen peroxide is added dropwise, keep React at 50°C for 6 hours, then wash with hot sodium carbonate solution, then wash with saturated brine until neutral, evaporate to remove water, then add 75 parts of potassium hydroxide ethanol solution in the reaction kettle, and react at a temperature of 60°C 40min to obtain the modified vegetable oil;

[0026] Mixing reaction: Add 22 parts of beeswax into a container and heat to 60°C to melt, then add 45 parts of modified vegetable oil, 15 parts of ionic liquid, 10 parts of glyceryl stearate, 3 parts of polyvinyl alcohol, 5 parts of polyethyleneimine, Mix and stir 3 parts of fungicide and 10 parts of sodium dodecylsulfonate for 5 minutes, and finally add 10 par...

Embodiment 3

[0028] Vegetable oil pre-modification: put 85 parts of vegetable oil into the reactor, add 23 parts of acetic acid solution and 3 parts of strong acid cationic resin catalyst, raise the temperature, and slowly add 50 parts of 30% hydrogen peroxide dropwise at the same time, after the dropwise addition of hydrogen peroxide, keep React at 52°C for 4 hours, then wash with hot sodium carbonate solution, then wash with saturated brine until neutral, evaporate to remove water, then add 75 parts of potassium hydroxide ethanol solution to the reaction kettle, and react at a temperature of 80°C 50min to obtain the modified vegetable oil;

[0029] Mixing reaction: Add 20 parts of beeswax into a container and heat to 80°C to melt, then add 50 parts of modified vegetable oil, 10 parts of ionic liquid, 6 parts of glyceryl stearate, 6 parts of polyvinyl alcohol, 2 parts of polyethyleneimine, 5 parts of fungicide and 8 parts of sodium dodecylsulfonate were mixed and stirred for 20 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com