Electrophoretic paint based on acrylic acid resin as well as processing process thereof

An acrylic resin, electrophoretic coating technology, applied in electrophoretic coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor acid and alkali resistance, and achieve the effect of strong integrity, guaranteed acid and alkali resistance, and accelerated drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

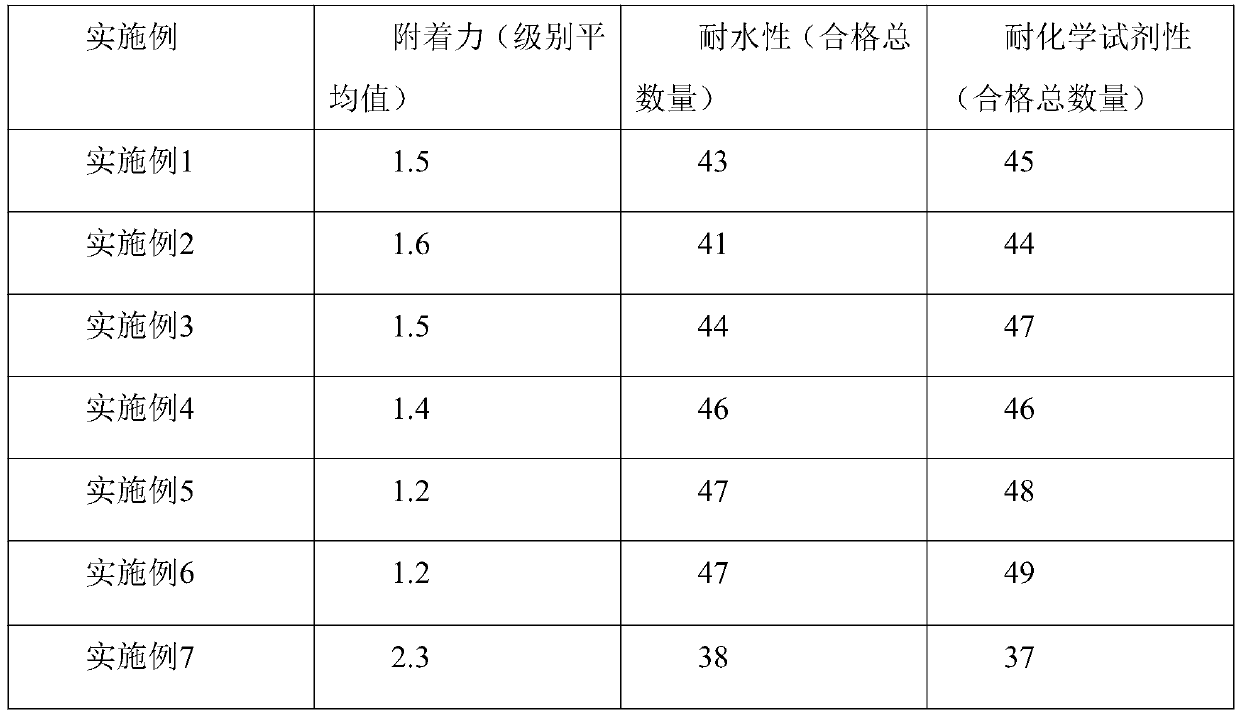

Examples

Embodiment 1

[0026] A kind of processing technology based on the electrophoretic paint of acrylic resin, comprises the following steps:

[0027] S1, in parts by mass, put 35 parts of acrylic resin, 15 parts of amino resin, 4 parts of trimethylolpropane and 5 parts of blocked isocyanate into a container for heating, and keep it at 80°C for 5 hours;

[0028] S2, quickly cool down S1 to minus 15°C, keep it for 0.5h, and then naturally warm up to room temperature to obtain mixture 1;

[0029] S3, mixing 8 parts of ethyl cellulose, 3 parts of dibutyl phthalate and 4 parts of polycaprolactone diol in parts by mass and grinding for 1 hour;

[0030] S4, adding 1 part of lead oxide to S3, and bathing in water at 65°C for 2 hours to obtain mixture 2;

[0031] S5, mixing and stirring the mixture 1 and the mixture 2 to obtain a paint.

Embodiment 2

[0033] A kind of processing technology based on the electrophoretic paint of acrylic resin, comprises the following steps:

[0034] S1, in parts by mass, put 50 parts of acrylic resin, 10 parts of amino resin, 6 parts of trimethylolpropane and 3 parts of blocked isocyanate into a container for heating, and keep it at 100°C for 3 hours;

[0035] S2, the temperature of S1 is rapidly cooled to minus 10°C, kept for 1 hour, and then naturally warmed to room temperature to obtain a mixture 1;

[0036] S3, mixing 5 parts of ethyl cellulose, 5 parts of dibutyl phthalate, 4 parts of phenolic resin and 2 parts of polycaprolactone diol in parts by mass and grinding for 1.5 hours;

[0037] S4, adding 2 parts of lead oxide to S3, and bathing in water at 50°C for 2.5 hours to obtain mixture 2;

[0038] S5, mixing and stirring the mixture 1 and the mixture 2 to obtain a paint.

Embodiment 3

[0040] A kind of processing technology based on the electrophoretic paint of acrylic resin, comprises the following steps:

[0041] S1, in parts by mass, put 40 parts of acrylic resin, 12 parts of amino resin, 5 parts of trimethylolpropane and 4 parts of blocked isocyanate into a container for heating, and keep it at 90°C for 4 hours;

[0042] S2, the temperature of S1 is rapidly cooled to minus 12°C, kept for 1.2h, and then naturally warmed to room temperature to obtain a mixture 1;

[0043] S3, mixing 6 parts of ethyl cellulose, 4 parts of dibutyl phthalate, 8 parts of phenolic resin, 2 parts of petroleum resin and 3 parts of polycaprolactone glycol in parts by mass and grinding for 1.2 hours;

[0044] S4, adding 1.5 parts of lead oxide to S3, and bathing in water at 55°C for 2.2 hours to obtain mixture 2;

[0045] S5, mixing and stirring the mixture 1 and the mixture 2 to obtain a paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com