Waterproofing agent with long-lasting water resistance for walls and processing technology of waterproofing agent

A processing technology and technology of waterproofing agent, applied in the field of processing technology of wall waterproofing agent, can solve problems such as reducing construction difficulty, and achieve the effects of improving compactness, good waterproof performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

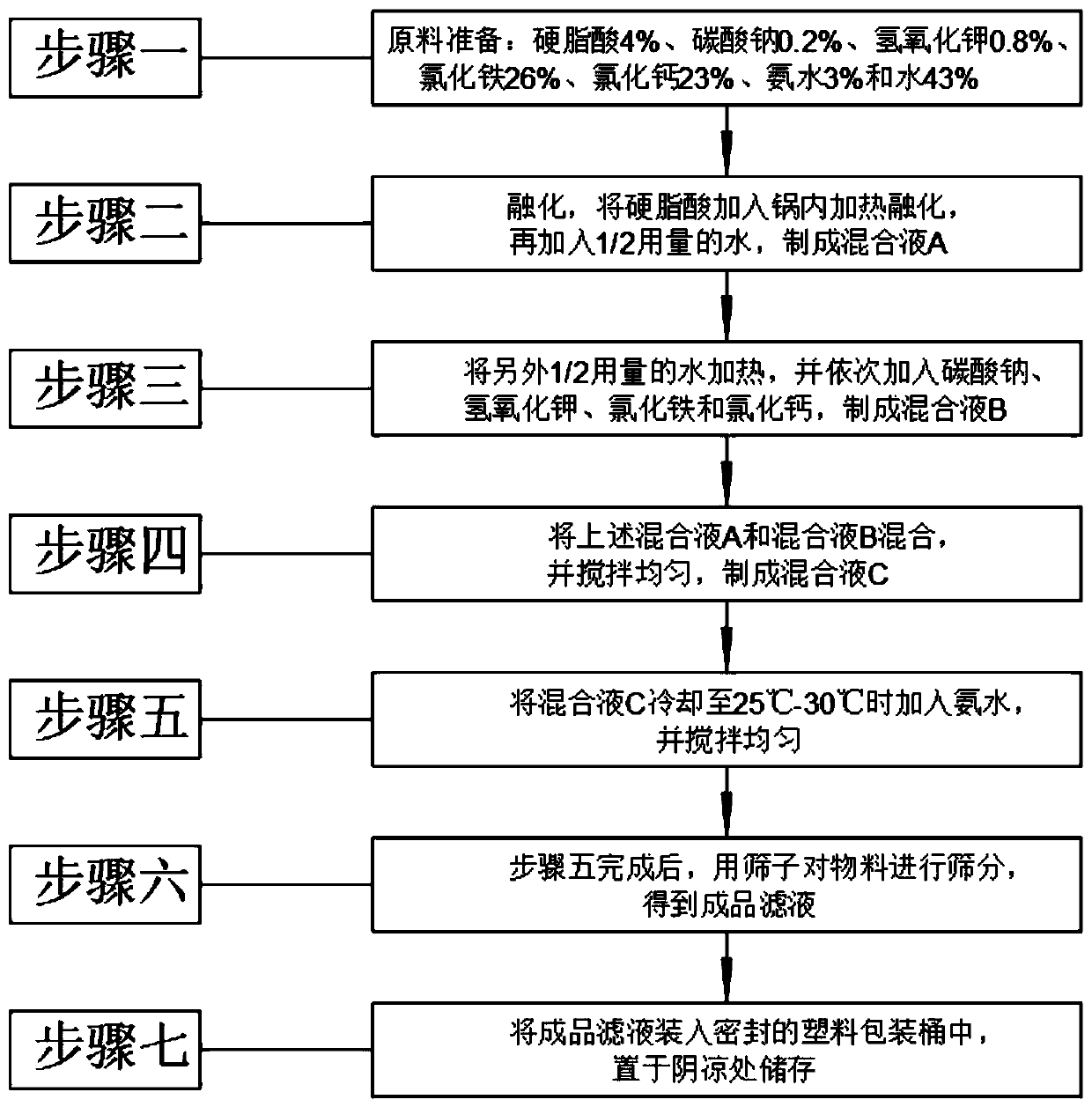

[0026] see figure 1 , the present invention provides a technical solution: a long-lasting waterproof wall waterproofing agent, including stearic acid, sodium carbonate, potassium hydroxide, ferric chloride, calcium chloride, ammonia and water; its components are by weight percentage Calculated as: stearic acid 3.2%, sodium carbonate 0.1%, potassium hydroxide 0.7%, ferric chloride 25%, calcium chloride 25%, ammonia 4% and water 42%.

[0027] A processing technology of a long-lasting waterproof wall waterproofing agent, comprising the following steps:

[0028] Step 1, raw material preparation: 3.2% stearic acid, 0.1% sodium carbonate, 0.7% potassium hydroxide, 25% ferric chloride, 25% calcium chloride, 4% ammonia and 42% water;

[0029] Stearic acid is a fatty acid that exists widely in nature. Stearic acid water repellents have good waterproof performance, long waterproof life, low process difficulty and low cost;

[0030] Sodium carbonate is an alkali metal compound. It is m...

Embodiment 2

[0039] see figure 1 , the present invention provides a technical solution: a long-lasting waterproof wall waterproofing agent, including stearic acid, sodium carbonate, potassium hydroxide, ferric chloride, calcium chloride, ammonia and water; its components are by weight percentage Calculated as: stearic acid 4%, sodium carbonate 0.2%, potassium hydroxide 0.8%, ferric chloride 26%, calcium chloride 23%, ammonia 3% and water 43%.

[0040] A processing technology of a long-lasting waterproof wall waterproofing agent, comprising the following steps:

[0041] Step 1, raw material preparation: 4% stearic acid, 0.2% sodium carbonate, 0.8% potassium hydroxide, 26% ferric chloride, 23% calcium chloride, 3% ammonia and 43% water;

[0042] Stearic acid is a fatty acid that exists widely in nature. Stearic acid water repellents have good waterproof performance, long waterproof life, low process difficulty and low cost;

[0043] Sodium carbonate is an alkali metal compound. It is mixed...

Embodiment 3

[0052] see figure 1 , the present invention provides a technical solution: a long-lasting waterproof wall waterproofing agent, including stearic acid, sodium carbonate, potassium hydroxide, ferric chloride, calcium chloride, ammonia and water; its components are by weight percentage Calculated as: stearic acid 5%, sodium carbonate 0.2%, potassium hydroxide 0.8%, ferric chloride 27%, calcium chloride 24%, ammonia 4% and water 43%.

[0053] In the present embodiment, preferably, its component by weight percentage is: stearic acid 5%, sodium carbonate 0.3%, potassium hydroxide 0.9%, ferric chloride 27%, calcium chloride 24%, ammoniacal liquor 4% and Water 44%.

[0054] A processing technology of a long-lasting waterproof wall waterproofing agent, comprising the following steps:

[0055] Step 1, raw material preparation: 4% stearic acid, 0.2% sodium carbonate, 0.8% potassium hydroxide, 26% ferric chloride, 23% calcium chloride, 3% ammonia and 43% water;

[0056] Stearic acid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com