Environment-friendly epichlorohydrin rubber material resistant to wear, heat and ageing

A chlorohydrin rubber and anti-aging technology, applied in the field of rubber materials, can solve problems such as endangering life safety and poor wear resistance of chlorohydrin rubber materials, and achieve the effects of good interface adsorption, enhanced mechanical properties, and small permanent compression deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

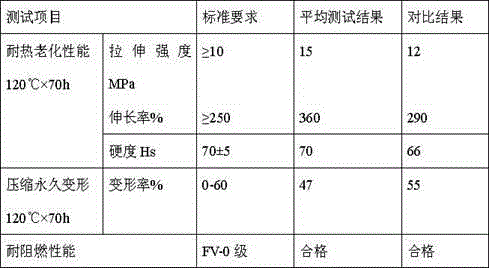

Examples

Embodiment 1

[0064] An environmentally friendly, wear-resistant, heat-resistant and aging-resistant chlorohydrin rubber material, the raw materials of which include by weight:

[0065] 40 parts of chlorohydrin rubber,

[0066] 40 parts of powdered nitrile rubber,

[0067] γ-(2,3-Glycidyloxy) Propyltrimethoxysilane 2 parts,

[0069] 1 part stearic acid,

[0070] Sulfur 2.5 parts,

[0071] 2 parts of dodecyl mercaptan,

[0072] 12 parts of decabromodiphenylethane,

[0073] Zinc borate 5 parts,

[0074] Tricresyl phosphate 15 parts,

[0075] Acetyl tributyl citrate 3 parts,

[0076] 15 parts of nano-aluminum nitride,

[0077] Nano Kaolin 20 parts,

[0078] Quickly squeeze out 60 parts of carbon black N550,

[0079] 2 parts paraffin,

[0080] Anti-aging agent RD 5 parts,

[0081] Anti-aging agent TPPD 1 part.

Embodiment 2

[0083] An environmentally friendly, wear-resistant, heat-resistant and aging-resistant chlorohydrin rubber material, the raw materials of which include by weight:

[0084] 50 parts of chlorohydrin rubber,

[0085] 30 parts of powdered nitrile rubber,

[0086] 5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane,

[0088] 3 parts stearic acid,

[0089] 2 parts sulfur,

[0090] 6 parts of dodecyl mercaptan,

[0091] 5 parts of decabromodiphenylethane,

[0092] Zinc borate 8 parts,

[0093] Tricresyl phosphate 10 parts,

[0094] Acetyl tributyl citrate 6 parts,

[0095] 10 parts of nano-aluminum nitride,

[0096] Nano Kaolin 25 parts,

[0097] Quickly squeeze out 40 parts of carbon black N550,

[0098] 3 parts paraffin,

[0099] Anti-aging agent RD 2 parts,

[0100] Anti-aging agent TPPD 3 parts.

Embodiment 3

[0102] An environmentally friendly, wear-resistant, heat-resistant and aging-resistant chlorohydrin rubber material, the raw materials of which include by weight:

[0103] 45 parts of chlorohydrin rubber,

[0104] 40 parts of powdered nitrile rubber,

[0105] γ-(2,3-Glycidyloxy) Propyltrimethoxysilane 2 parts,

[0106] Zinc oxide 2.5 parts,

[0107] 1 part stearic acid,

[0108] Sulfur 2.5 parts,

[0109] 2 parts of dodecyl mercaptan,

[0110] 8 parts of decabromodiphenylethane,

[0111] Zinc borate 6 parts,

[0112] 14 parts of tricresyl phosphate,

[0113] Acetyl tributyl citrate 4 parts,

[0114] 14 parts of nano-aluminum nitride,

[0115] Nano Kaolin 20 parts,

[0116] Quickly squeeze out 58 parts of carbon black N550,

[0117] 2 parts paraffin,

[0118] Anti-aging agent RD 4 parts,

[0119] Anti-aging agent TPPD 2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com