Environment-friendly high-performance chlorohydrin rubber material

A chlorohydrin rubber and high-performance technology, applied in the field of environmentally friendly high-performance chlorohydrin rubber materials, can solve problems such as endangering life and safety, and achieve the effects of good heat resistance, small permanent compression deformation, and enhanced aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

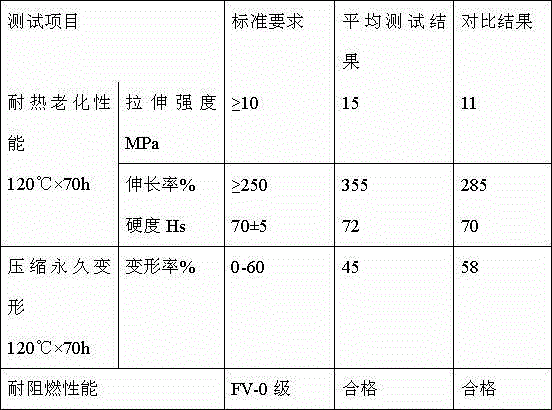

Examples

Embodiment 1

[0061] A kind of environment-friendly high-performance chlorohydrin rubber material, its raw material comprises by weight:

[0062] 30 parts of chlorohydrin rubber,

[0063] Neoprene 40 parts,

[0064] Zinc oxide 4 parts,

[0065] Magnesium oxide 5 parts,

[0066] Lead-free vulcanizing agent XL-21S 5 parts,

[0067] 9 parts of antimony trioxide,

[0068] 5 parts of decabromodiphenylethane,

[0069] Zinc borate 8 parts,

[0070] 8 parts of tricresyl phosphate,

[0071] Acetyl tributyl citrate 5 parts,

[0072] Nano nylon 6 3 parts,

[0073] 8 parts of nano-montmorillonite,

[0074] Quickly squeeze out 40 parts of carbon black N550,

[0075] 3 parts paraffin,

[0076] Anti-aging agent RD 2 parts,

[0077] Antiaging agent 4010NA 3 parts.

Embodiment 2

[0079] A kind of environment-friendly high-performance chlorohydrin rubber material, its raw material comprises by weight:

[0080] Chlorohydrin rubber 70 parts,

[0081] Neoprene 20 parts,

[0082] Zinc oxide 6 parts,

[0083] Magnesium oxide 3 parts,

[0084] Lead-free curing agent XL-21S 12 parts,

[0085] 3 parts of antimony trioxide,

[0086] 10 parts of decabromodiphenylethane,

[0087] Zinc borate 5 parts,

[0088] 12 parts of tricresyl phosphate,

[0089] Acetyl tributyl citrate 2 parts,

[0090] Nano nylon 6 6 parts,

[0091] 5 parts of nano-montmorillonite,

[0092] Quickly squeeze out 60 parts of carbon black N550,

[0093] 2 parts paraffin,

[0094] Anti-aging agent RD 5 parts,

[0095] Antiaging agent 4010NA 1 part.

Embodiment 3

[0097] A kind of environment-friendly high-performance chlorohydrin rubber material, its raw material comprises by weight:

[0098] 50 parts of chlorohydrin rubber,

[0099] Neoprene 35 parts,

[0100] Zinc oxide 4 parts,

[0101] Magnesium oxide 4 parts,

[0102] Lead-free curing agent XL-21S 6 parts,

[0103] 8 parts of antimony trioxide,

[0104] 8 parts of decabromodiphenylethane,

[0105] Zinc borate 8 parts,

[0106] Tricresyl phosphate 10 parts,

[0107] Acetyl tributyl citrate 4 parts,

[0108] Nano nylon 6 3 parts,

[0109] 8 parts of nano-montmorillonite,

[0110] Quickly squeeze out 50 parts of carbon black N550,

[0111] 3 parts paraffin,

[0112] Anti-aging agent RD 2 parts,

[0113] Antiaging agent 4010NA 2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com