Manufacturing method of polyamide 56 industrial yarn for airbags

An airbag and polyamide technology, which is applied in the field of polyamide fiber, can solve the problems of unfavorable airbags, product performance retention time, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

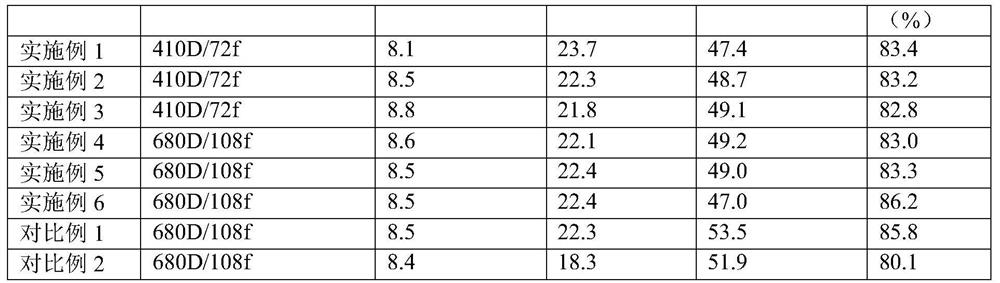

Examples

preparation example Construction

[0040] A preparation method of polyamide 56 industrial yarn for airbag, comprising the following steps:

[0041] 1) Dissolve bio-based pentamethylenediamine in a solvent at 30-80°C to prepare a 30-70wt% amine solution; at the same time dissolve adipic acid in the same solvent at 30-80°C to prepare an acid The mass fraction of the acid solution is 30-70wt%; then the amine solution is added to the acid solution under stirring, the molar ratio of the amine group to the carboxyl group is 1 to 1.002:1, the temperature is kept at 50-90°C, and the stirring is continued for 30 After -120min, the resulting mixed solution was cooled to 0-20°C and left to stand for 2-6 hours, and the precipitated crystals were filtered, washed and dried to obtain the 56 salt. The solvent is one of water, ethanol, methanol and acetonitrile.

[0042] 2) Prepare the obtained 56 salt into a 30-70wt% aqueous solution, add a nucleating agent and an auxiliary agent, and carry out a polymerization reaction: fir...

Embodiment 1

[0056] The first step: the preparation of 56 salts, dissolving bio-based pentamethylenediamine in ethanol at 75°C to prepare an amine solution with a mass fraction of pentamethylenediamine of 67wt%; Dissolve in the same solvent, and prepare an acid solution with an acid mass fraction of 65wt%; then, under the action of mechanical stirring, add the amine solution into the acid solution, keep the temperature at 80°C, and continue mechanical stirring for 65 minutes , the mixed solution was cooled to 11°C, and stood still for 5 hours. During this process, the 56 salt crystallized and precipitated, and finally the 56 salt was obtained after filtration, washing and drying.

[0057] The second step: the 56 salt obtained in the first step is prepared into a 65wt% aqueous solution, and mixed with talcum powder, the addition amount is 1.5wt%, HOOC (CH 2 ) 4 COOH, the addition amount is 0.1wt%, 4-amino-2,2,6,6-tetramethylpiperidine, the addition amount is 0.5wt%, carry out the polymeriz...

Embodiment 2

[0061] The first step: the preparation of the 56 salt, the bio-based pentamethylenediamine was dissolved in water at 60°C to prepare an amine solution with a mass fraction of pentamethylenediamine of 55wt%; at the same time, adipic acid was dissolved at 65°C , dissolved in the same solvent, and prepared into an acid solution with an acid mass fraction of 55wt%; then under the action of mechanical stirring, the amine solution was added to the acid solution, and the temperature was kept at 75°C. After continuous mechanical stirring for 90 minutes, The mixed solution was cooled to 4°C and allowed to stand for 5 hours. During this process, the 56 salt was cooled and crystallized. Finally, the 56 salt was obtained by filtering, washing and drying.

[0062] The second step: the 56 salt obtained in the first step is formulated into a 60wt% aqueous solution, and the nucleating agent is mixed with sodium dihydrogen phosphate, the addition amount is 1.2wt%, and terephthalic acid, the add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com