A kind of bacterial cellulose composite film with high orientation and high strength and its preparation and application

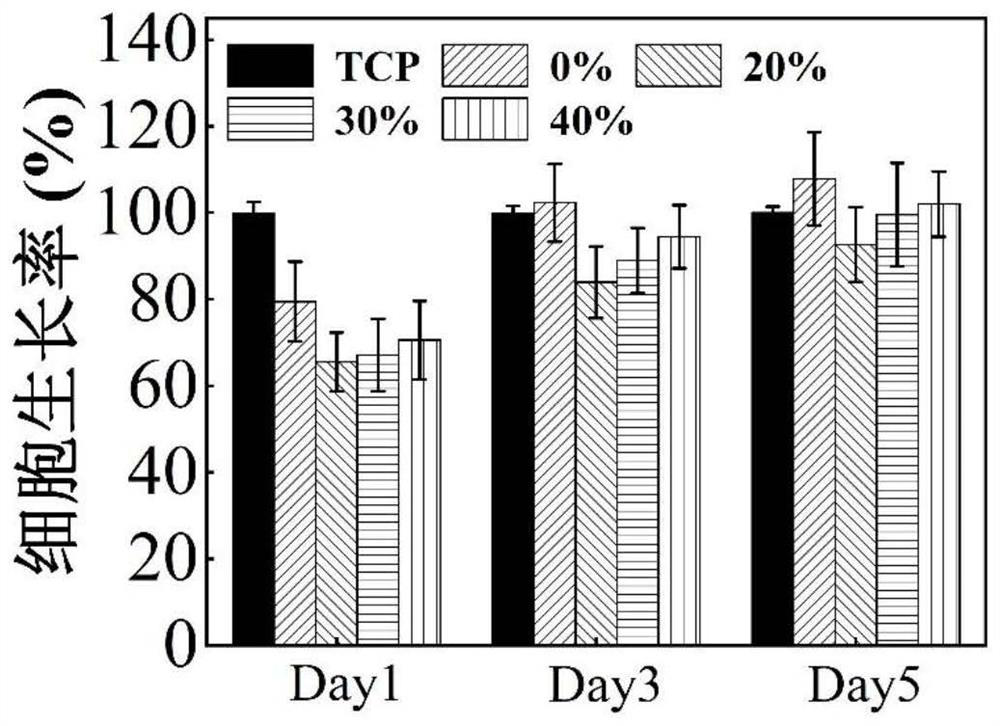

A technology of bacterial cellulose film and bacterial cellulose, applied in bandages, absorbent pads, medical science, etc., can solve problems such as low mechanical strength and poor biocompatibility, achieve simple preparation process, promote wound healing, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

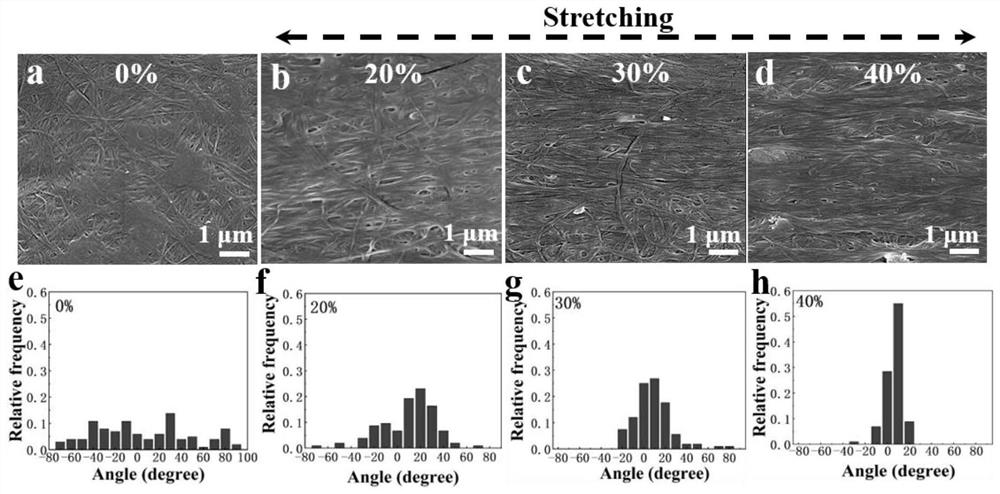

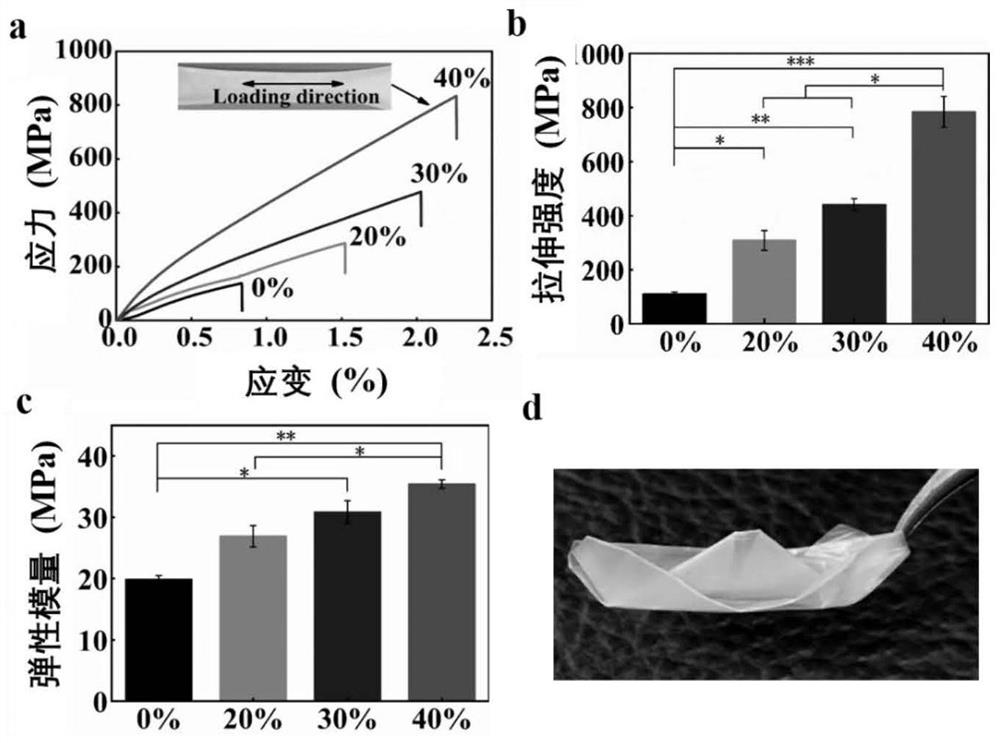

[0040] A kind of preparation method of the bacterial cellulose composite membrane of high orientation and high strength of the present invention comprises the following steps:

[0041] (1) By adopting the method of mechanical stretching, bacterial cellulose with a length of 8cm-15cm (preferably 12cm) and a width of 1cm-8cm (preferably 4cm) is used to prepare bacterial cellulose (BC) with different tensile strains. ); Tensile strain is less than or equal to 40% (preferably 40%);

[0042] (2) soak the bacterial cellulose (BC) film prepared in step (1) into a certain concentration of natural polymer solution, the soaking time is 3h-24h (preferably 6h), and the temperature is 30-50°C (preferably 37° C.), and shake fully on a shaker at a speed of 50-200 rpm (preferably 150 rpm), and then form a bacterial cellulose composite film under the action of a crosslinking agent. The specific reaction is that under the action of the cross-linking agent, the carboxyl group on the natural pol...

Embodiment 1

[0048] (1) Cutting the original BC film to a length of 12 cm and a width of 4 cm; preparing a BC with a tensile strain of 20% by mechanical stretching;

[0049] (2) Soak the BC membrane prepared in step (1) into a 1% gelatin solution, fully shake it on a shaker for 6 hours, the temperature is 37°C, and the shaking speed is 150rpm, and then put it in the EDC / NHS cross-linking agent The BC / gelatin composite film was formed by cross-linking for 4 hours, and washed three times with deionized water.

[0050] (3) Hot pressing the BC / gelatin composite film prepared in step (2), the hot pressing stress is 100N; the hot pressing temperature is 60°C; the hot pressing time is 24h; Composite film of BC / gelatin.

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that the tensile strain of BC is different, and the tensile strain of this embodiment is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com