Vulcanized butyl pressure-sensitive adhesive

A pressure-sensitive adhesive and vulcanization-type technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as poor heat resistance, decreased force between chains, and small cohesive energy, and achieve improved Cohesive energy and heat resistance, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

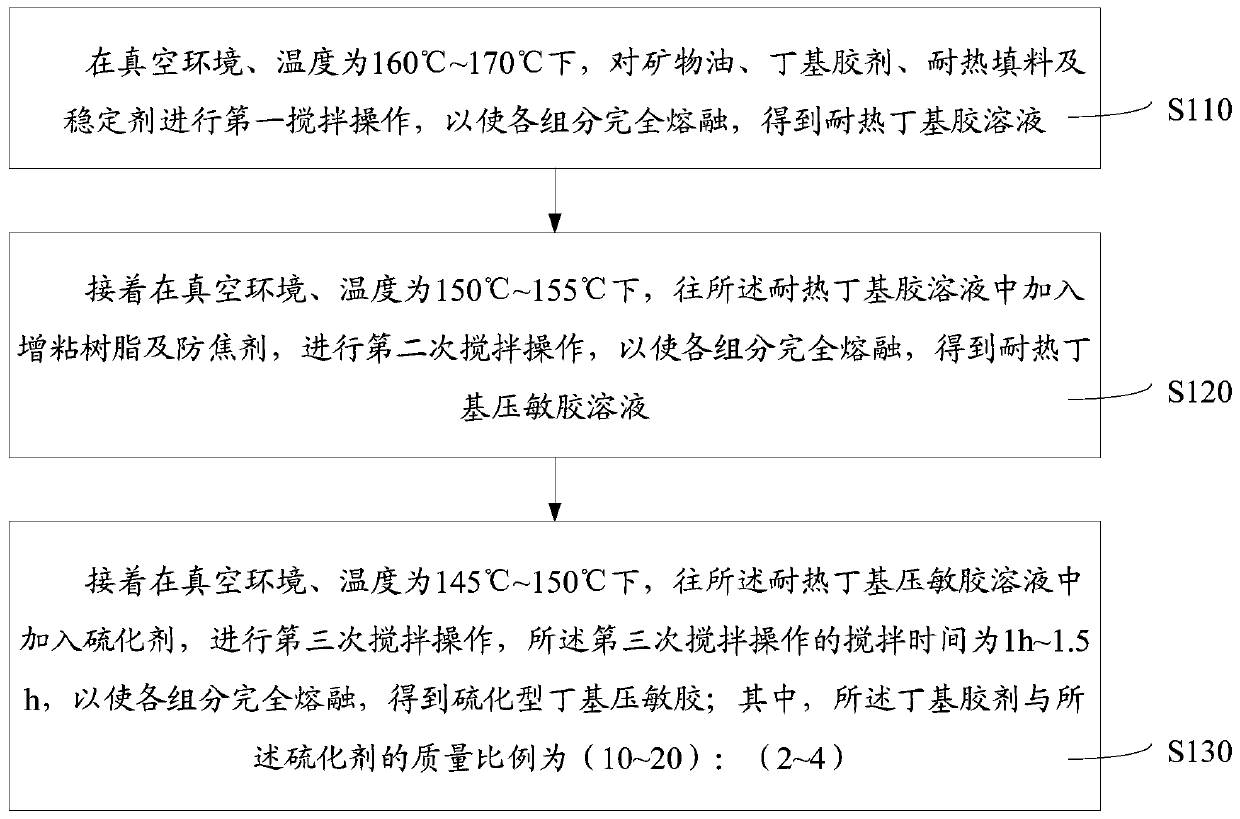

Method used

Image

Examples

Embodiment approach

[0026] In order to better illustrate the vulcanized butyl pressure-sensitive adhesive, to better understand the concept of the vulcanized butyl pressure-sensitive adhesive. One embodiment, a vulcanized butyl pressure-sensitive adhesive, comprising the following components in parts by mass: 30-40 parts of mineral oil, 10-20 parts of butyl adhesive, 20-40 parts of heat-resistant filler, 2 parts of vulcanizing agent ~4 parts, anti-scorch agent 0.1-0.4 parts, stabilizer 1-5 parts and tackifying resin 20-30 parts. It should be noted that butyl adhesive is the main polymer of vulcanized butyl pressure-sensitive adhesive, which mainly endows vulcanized butyl pressure-sensitive adhesive with properties such as viscoelasticity, cohesive strength and medium resistance. Mineral oil has a plasticizing effect, which can reduce the hardness and viscosity of butyl rubber, improve the processing performance and low temperature resistance of butyl rubber. Heat-resistant fillers can improve th...

Embodiment 1

[0052] S111, in a vacuum environment at a temperature of 160 ° C, 30kg polyisobutylene, 20kg butyl rubber, 10kg calcium carbonate, 5kg talcum powder, 5kg titanium dioxide, 2kg tetrakis [β-(3,5-tertiary butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester and 3kg2-hydroxyl-4-methoxy-5-sulfonic acid benzophenone were stirred for 40min at a stirring rate of 50rpm / min, so that each component was completely melted to obtain heat-resistant Butyl gum solution;

[0053] S121, then add 5 kg of petroleum resin, 15 kg of phenolic resin and 0.4 kg of N-nitrosoaniline to the heat-resistant butyl rubber solution in a vacuum environment at a temperature of 155° C., and stir for 40 min at a stirring rate of 40 rpm / min, To make each component melt completely to obtain a heat-resistant butyl pressure-sensitive adhesive solution;

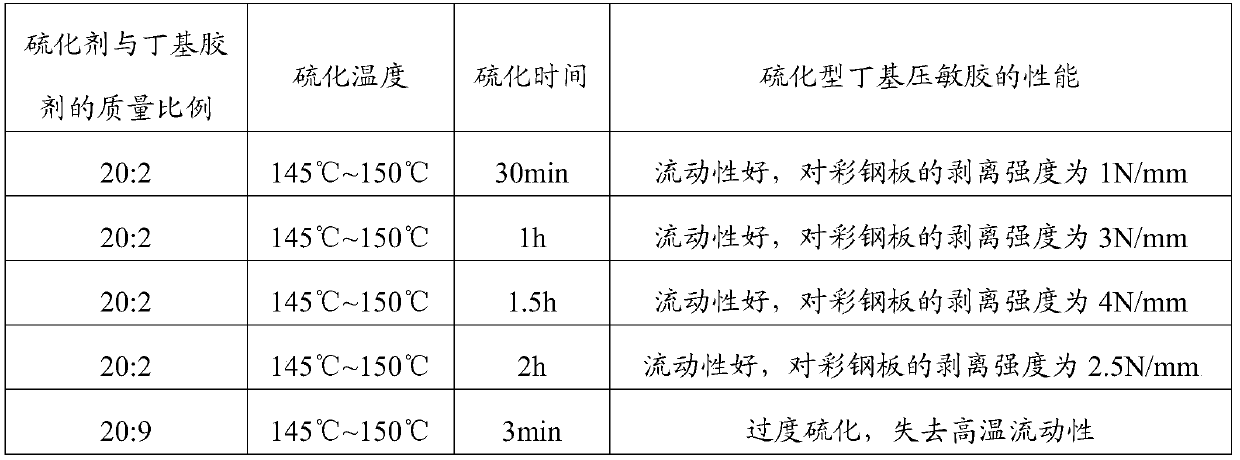

[0054] S131, then add 2kg of alkylphenol-formaldehyde resin to the heat-resistant butyl pressure-sensitive adhesive solution in a vacuum environment at a temp...

Embodiment 2

[0056] S112, in a vacuum environment at a temperature of 170°C, 40kg of polyisobutylene, 10kg of butyl rubber, 25kg of calcium carbonate, 5kg of talc, 10kg of titanium dioxide, and 0.5kg of tetra[β-(3,5-tertiary butyl- 4-hydroxyphenyl) propionic acid] pentaerythritol ester and 0.5kg2-hydroxyl-4-methoxy-5-sulfonic acid benzophenone were stirred for 20min at a stirring rate of 70rpm / min, so that each component was completely melted to obtain Heat-resistant butyl rubber solution;

[0057] S122, then add 5 kg of petroleum resin, 25 kg of phenolic resin and 0.1 kg of N-nitrosoaniline to the heat-resistant butyl rubber solution in a vacuum environment at a temperature of 150° C., and stir at a stirring rate of 60 rpm / min for 20 min, To make each component melt completely to obtain a heat-resistant butyl pressure-sensitive adhesive solution;

[0058] S132, then, in a vacuum environment at a temperature of 150°C, add 4kg of alkylphenol-formaldehyde resin to the heat-resistant butyl p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com