Spraying-free high-flowability high-impact flame-retardant PC material with metal texture and preparation method and application of material

A technology of metal powder and flame retardant, which is applied in the field of materials, can solve the problem of difficulty in preparing materials with fluidity, impact performance and flame retardancy, inability to balance fluidity, impact performance and flame retardancy, and decline in mechanical properties and impact resistance, etc. problems, to achieve the effect of facilitating mass production, improving impact performance and appearance, and improving metal texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

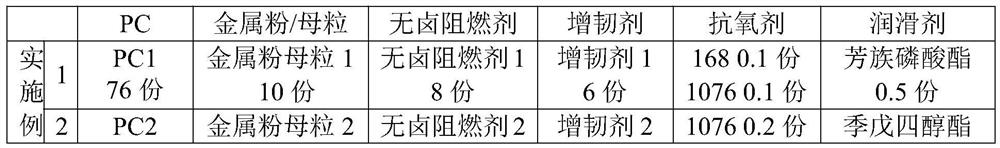

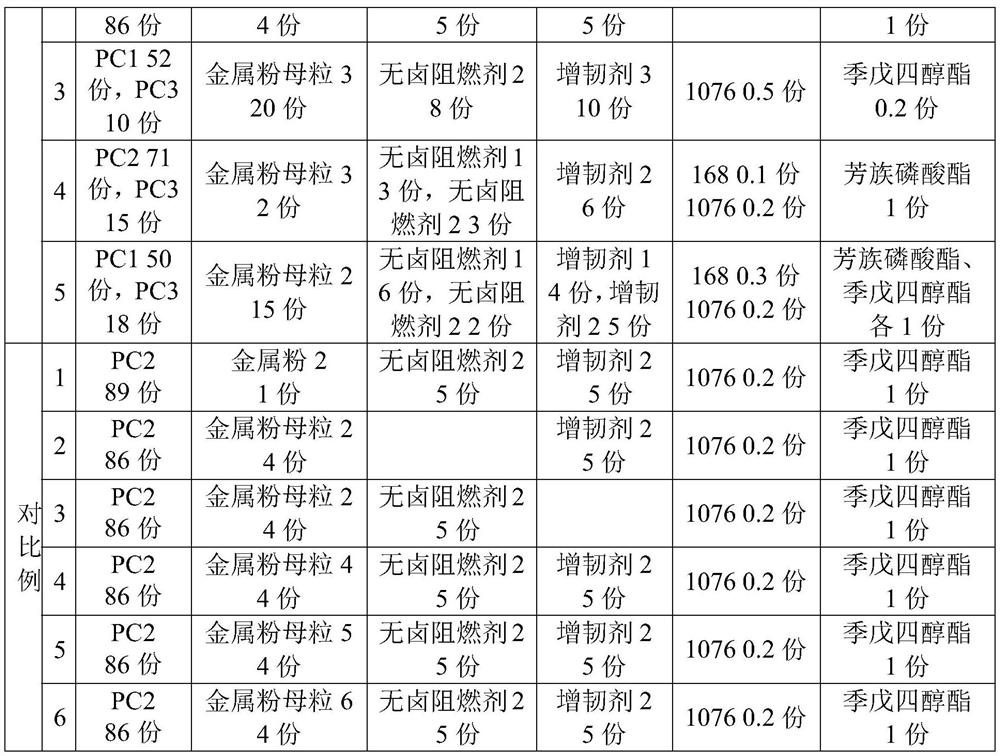

[0052] This embodiment relates to a high-flow, high-impact flame-retardant PC material with a metallic texture and no spraying, and its composition is shown in Tables 1 and 2;

[0053] The preparation method of the high-flow high-impact flame-retardant PC material of the present embodiment comprises the following steps:

[0054] (1) First prepare metal powder masterbatch 1: pre-mix 85 parts of MAH-St-MMA1 copolymer, 1680.2 parts of antioxidant, and 0.5 part of lubricant aromatic phosphate in the mixer, and then pre-mix The material is extruded through a twin-screw extruder, and at the same time, 115 parts of metal powder are added to the melt according to the ratio by side feeding, and the metal powder masterbatch is obtained by extrusion. Wherein the temperature of the extruder used is 200-230° C., the length-to-diameter ratio of the screw is 25, and the screw speed is 400 rpm.

[0055] (2) By weight, 176 parts of PC, 110 parts of metal powder masterbatch, 18 parts of haloge...

Embodiment 2

[0057] This embodiment relates to a high-flow, high-impact flame-retardant PC material with a metallic texture and no spraying, and its composition is shown in Tables 1 and 2;

[0058] The preparation method of the high-flow high-impact flame-retardant PC material of the present embodiment comprises the following steps:

[0059] (1) First prepare metal powder masterbatch 2: 75 parts by weight of MAH-St-MMA2 copolymer, 10760.2 parts of antioxidant, 0.5 part of pentaerythritol ester of lubricant are premixed in the mixer, and then the premixed material is passed through Extruded by a twin-screw extruder, and at the same time, 225 parts of metal powder were added to the melt according to the ratio by side feeding, and extruded to obtain metal powder master batches. Wherein the temperature of the extruder used is 200-230° C., the length-to-diameter ratio of the screw is 35, and the screw speed is 600 rpm.

[0060] (2) Pre-mix 286 parts of PC, 24 parts of metal powder masterbatch,...

Embodiment 3

[0062] This embodiment relates to a high-flow, high-impact flame-retardant PC material with a metallic texture and no spraying, and its composition is shown in Tables 1 and 2;

[0063] The preparation method of the high-flow high-impact flame-retardant PC material of the present embodiment comprises the following steps:

[0064] (1) First prepare metal powder masterbatch 3: 99 parts by weight of MAH-St-MMA3 copolymer, 10760.2 parts of antioxidant, and 0.5 part of pentaerythritol ester of lubricant are premixed in the mixer, and then the premixed material is passed through Extruded by a twin-screw extruder, and at the same time, 31 parts of metal powder were added to the melt by side feeding according to the proportion, and extruded to obtain metal powder masterbatch. Wherein the temperature of the extruder used is 220-250° C., the length-to-diameter ratio of the screw is 25, and the screw speed is 500 rpm.

[0065] (2) By weight, 152 parts of PC, 310 parts of PC, 320 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com