Composite material of similar fluid inorganic nano particle and polymer and preparation thereof

A technology of inorganic nanoparticles and composite materials, which is applied in the field of composite materials and preparation of fluid inorganic nanoparticles and polymers, and can solve the problem that no new composite materials of fluid-like inorganic nanoparticles and polymers have been seen, and transparent sheets cannot be prepared. Compatible with film and composite material application limitations, etc., to achieve the effect of strong plasticity, low manufacturing cost, and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

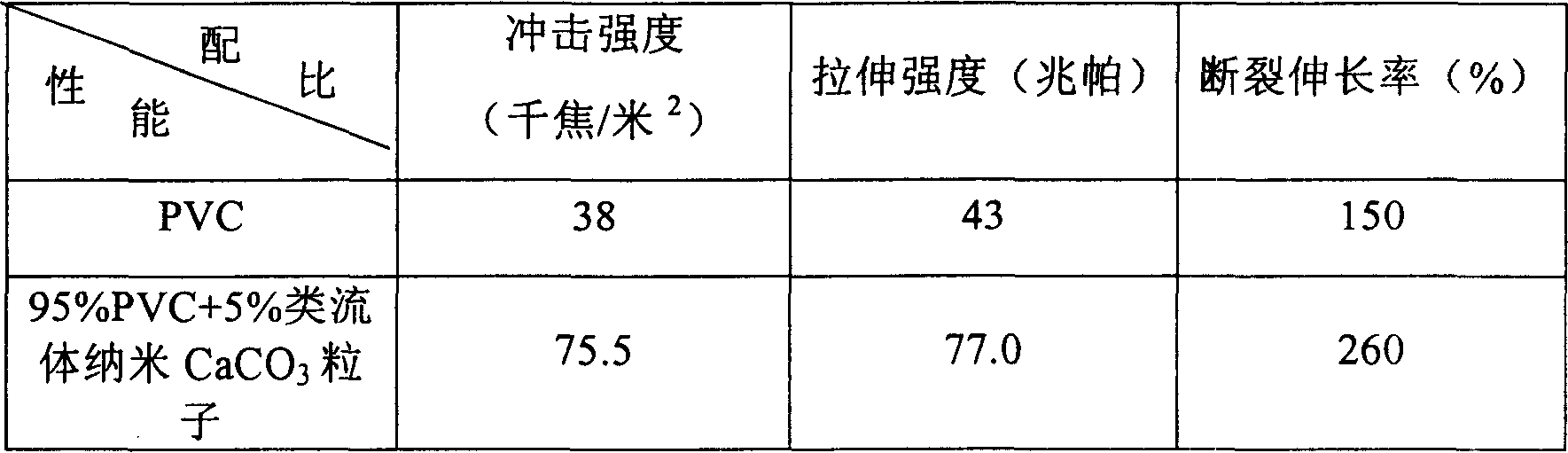

[0021] Mix 3 parts fluid-like nanometer CaCO by volume ratio 3 Particles (5-40 nanometers) and 97 parts of PVC are mixed evenly, and then plasticized and mixed in an extruder at a temperature of 160±20°C and a speed of 15±5 rpm, and finally calendered on a calender at a calendering temperature of 170±10°C. A transparent composite film is obtained. Data are as follows:

[0022]

Embodiment 2

[0024] Fluid-like nano-SiO with a volume ratio of 8-10 parts 2 Particles (5-20 nanometers) and 90-92 parts of polypropylene are uniformly mixed, extruded in an extruder at 175±25° C., and the screw speed is 30±10 revolutions / minute to prepare a composite material plate.

Embodiment 3

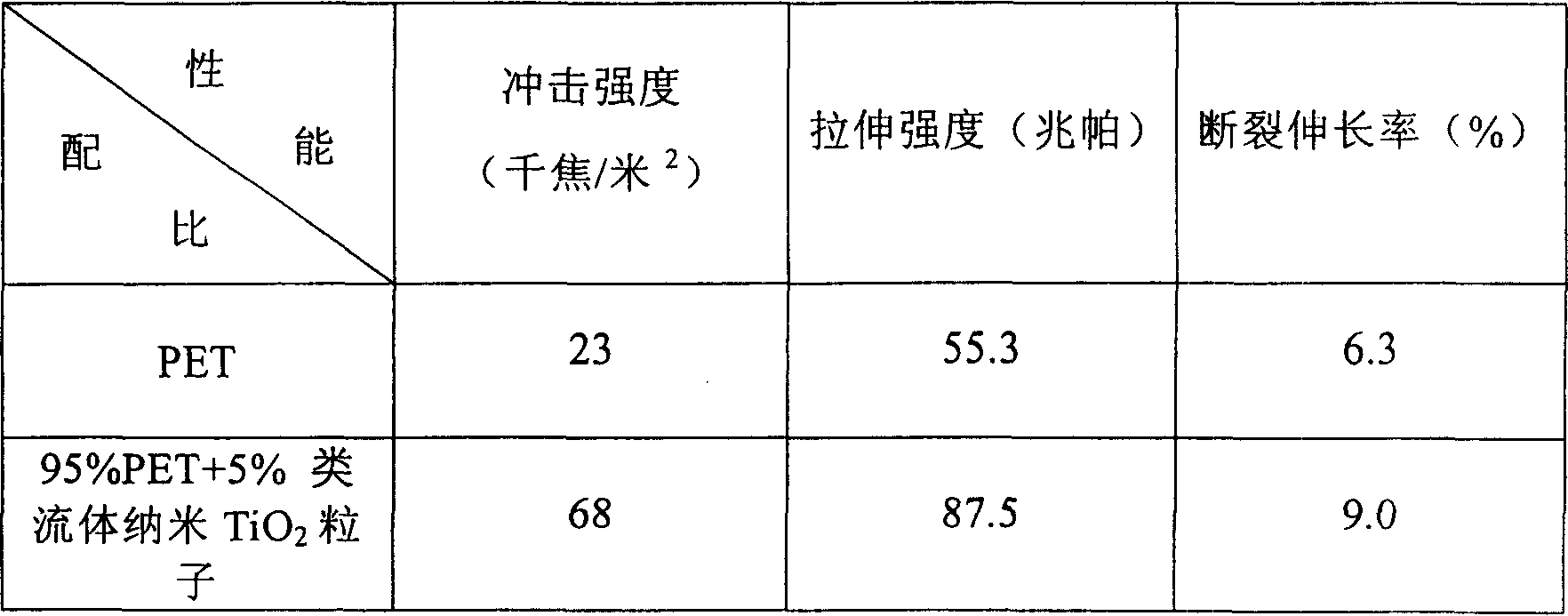

[0026] Fluid-like nano-TiO in volume ratio of 2 to 5 parts 2 Particles (10-30 nanometers) and 95-97 parts of polyester are mixed evenly, melted and extruded to granulate, and the temperature of the four-stage heating zone from the feed inlet to the extruder head is 240°C, 260°C, 260°C and 250°C respectively. °C, the screw speed is 30 rpm. Finally, they are calendered and formed on a calender at a temperature of 220±10° C. respectively. Fluid-like TiO 2 Particle / polyester composite film. Its mechanical properties are as follows.

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com