Chinese chestnut steamed corn bread and preparation method thereof

A chestnut and cornbread technology, applied in food ingredients as taste improvers, functions of food ingredients, food science, etc., can solve problems such as loss of flavor, lack of aroma of chestnuts, etc., and achieve the effect of luster without cracks, easy molding, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A chestnut cornbread, comprising the following raw materials in parts by weight: 500-800 parts of crushed chestnut kernels, 500 parts of mixed powder, 100 parts of crushed red dates, 80-120 parts of xylitol and 500 parts of purified water;

[0041] Wherein, the mixed flour includes glutinous rice flour and corn flour, and its weight ratio is (2:1)-(1:2).

[0042] In order to further optimize the above-mentioned technical scheme, the average particle size of the broken chestnut kernels is 2-7mm.

[0043] In order to further optimize the above-mentioned technical scheme, the particle size of the crushed red dates is 3-5mm.

Embodiment 2

[0045] A kind of preparation method of Chinese chestnut cornbread is provided on the basis of embodiment 1, specifically comprises the steps:

[0046] 1) Pretreatment of raw materials:

[0047] Wash the chestnuts, remove the shells and inner skin, steam them, cool them to room temperature, crush them to a particle size of 2-7 mm, and set aside;

[0048] Wash the red dates, dry them, remove the pits, cut them into crushed red dates with an average particle size of 3-5 mm, and set aside;

[0049] 2) According to the chestnut cornbread provided in Example 1, each raw material was weighed, mixed evenly and reconciled into a dough shape, and placed at room temperature;

[0050] 3) Wrap the dough processed in step 2) on the mold, trim it while rotating, remove it after forming, put it in a steamer, and steam it until it is cooked.

[0051] In order to further optimize the above-mentioned technical scheme, step 1) steaming for 20-30min.

[0052] In order to further optimize the ab...

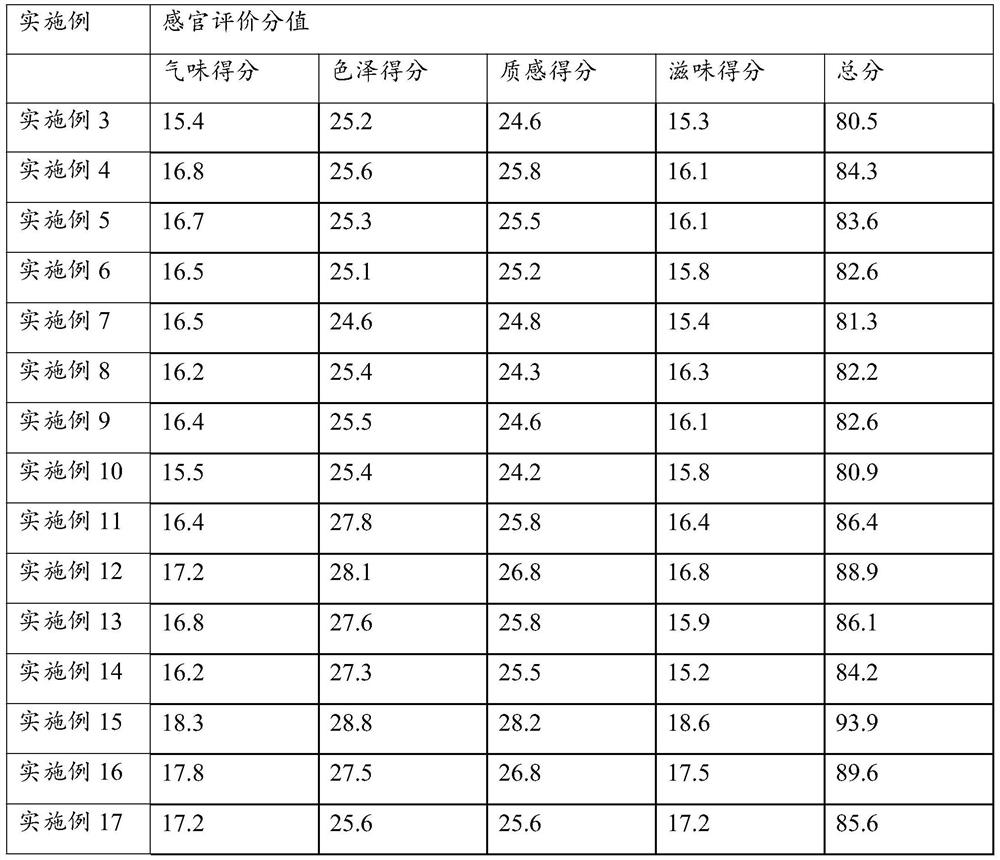

Embodiment 3

[0055] A chestnut cornbread, comprising the following raw materials in parts by weight: 500 g of crushed chestnut kernels, 500 g of mixed powder, 100 g of crushed red dates, 80 g of xylitol and 500 g of purified water;

[0056]Wherein, the mixed flour includes glutinous rice flour and corn flour, and its weight ratio is 1:1.

[0057] In order to further optimize the above-mentioned technical scheme, the average particle size of the broken chestnut kernels is 2-3mm.

[0058] In order to further optimize the above-mentioned technical scheme, the particle size of the crushed red dates is 3-5mm.

[0059] And prepare chestnut cornbread according to the preparation method of embodiment 2, repeat three times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com