Longitudinal reinforced polymer profile

A polymer and longitudinal technology, applied in the field of longitudinally reinforced polymer profiles, can solve problems such as insufficient material performance, waste of reinforced materials, processing technology, complexity, etc., and achieve the effects of simple installation, strong deformation resistance, and many varieties of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] (1) Extrusion molding process

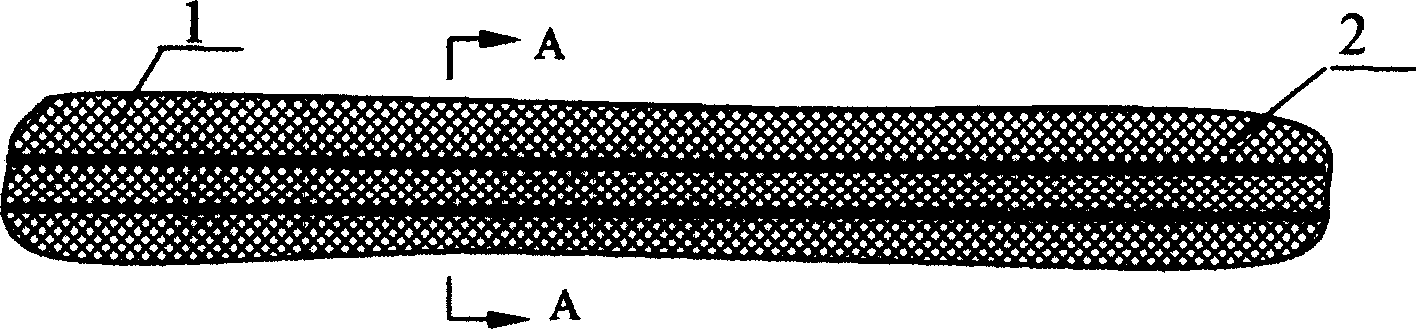

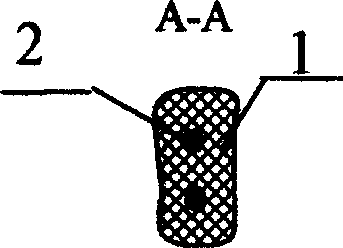

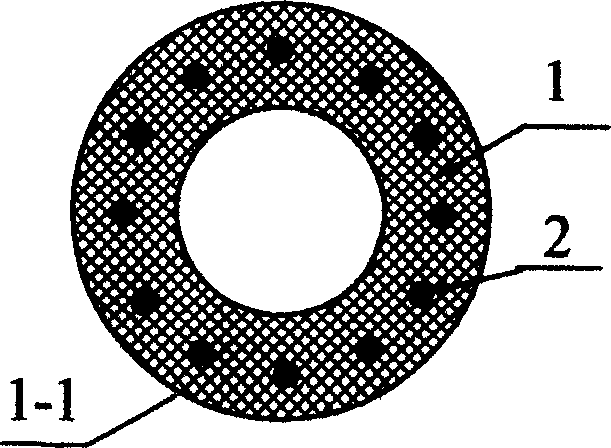

[0020] The matrix material 1 of the longitudinally reinforced polymer profile adopts extruded polyurethane (TPU), polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE), etc. and between them or between rubber and plastic elastomers The blended modified material, and the steel wire, steel strand, steel wire rope, fiber and fiber rope and other linear reinforcement materials 2 whose surface has been treated by degreasing, rust removal, activation and other processes, are processed by extrusion molding . The forming section of the extrusion die is made according to the needs image 3 As shown in various cross-sectional shapes or other shapes, the extrusion die mouth is provided with reinforcing material 2 positioning outlet holes, and the reinforcing material 2 is co-extruded synchronously while extruding the base material 1 . The leading-out direction of the reinforcing material is the molding direction of the profile, which for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com