Resilient intermediate piece for clamping rail base

A technology of intermediate parts and elastic parts, applied in the directions of rails, fixed rails, roads, etc., can solve the problems of wear and tear of spring parts, material fatigue, etc., and achieve the effect of strong shock absorption, effective shock absorption and small rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

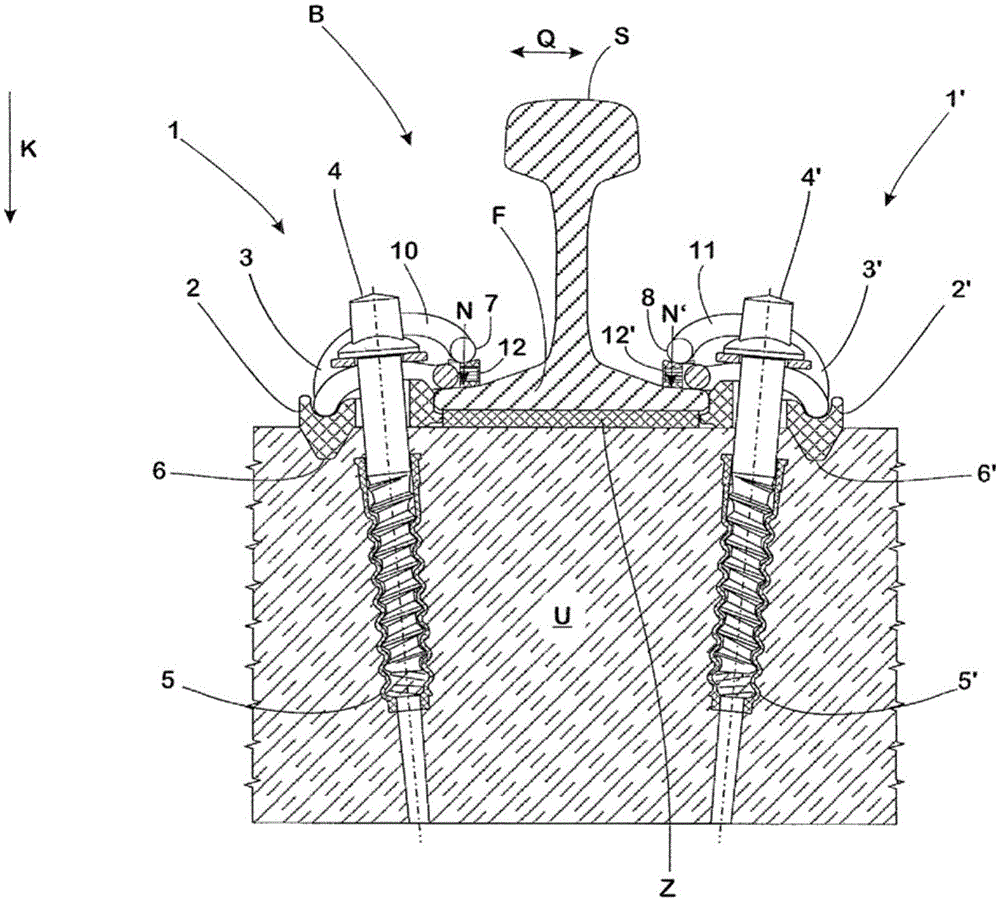

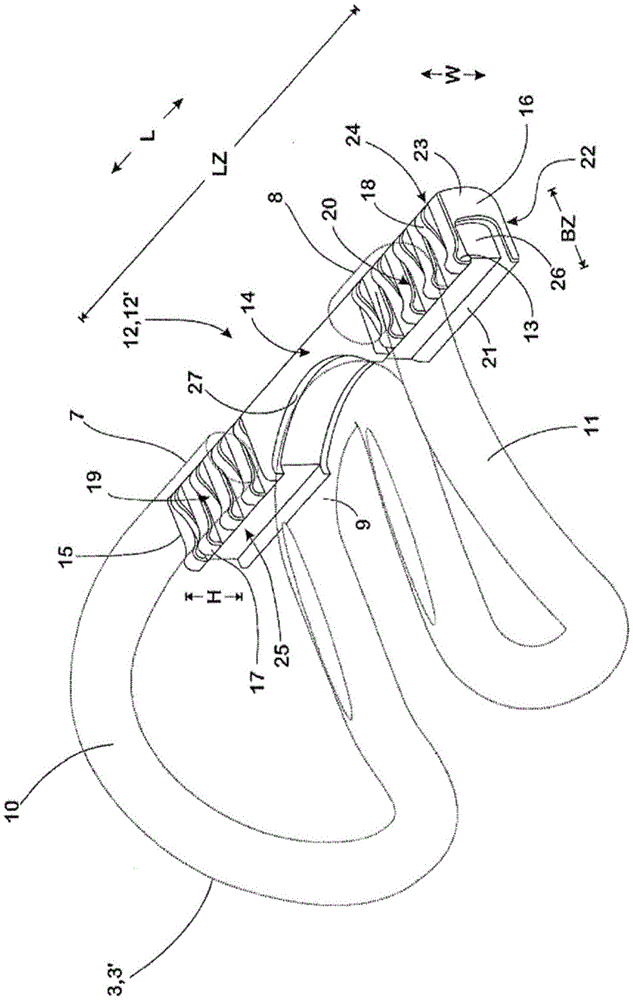

[0031] figure 1The fixing point B shown in includes two systems 1, 1' of identical construction for fixing a rail S formed in conventional form on a solid base U formed, for example, by concrete sleepers or concrete slabs. The systems 1 , 1 ′ are arranged on the longitudinal sides of the track S in each case. The rail S is part of a rail for a rail vehicle, not shown further, and has a rail foot F, a web lying thereon and a rail head supported by the web, on the free surface of which the rail vehicle is formed. The running surface of the wheel.

[0032] The systems 1 , 1 ′ each comprise a guide plate 2 , 2 ′, on which a spring member 3 , 3 ′ formed as a conventional W-shaped tensioning clip respectively sits. The spring parts 3, 3' are respectively tensioned relative to the base U by a tensioning part 4, 4' formed as a conventional sleeper bolt, which is inserted through the respective guide plate 2, 2' and extends from its upper side to Its underside passes through and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com