Modified polypropylene zipper material for liquid packaging and preparation method thereof

A technology for polypropylene and packaging, applied in the field of zipper composite bags, can solve the problems of PP zipper materials such as brittleness, difficulty in flatness, low temperature resistance, etc., achieve high room temperature impact strength and low temperature resistance impact strength, and improve radiation resistance , to achieve the effect of cryogenic storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

[0061] Prepare nucleating and smooth masterbatch by strand cutting, comprising the following steps;

[0062] Weigh erucamide or oleamide, inorganic silica, nucleating agent and polypropylene in proportion. Among them, the particle size of inorganic silica is about 5 μm, the nucleating agent is phosphate nucleating agent NA-21, the polypropylene is ethylene propylene binary copolymerized polypropylene, and the melting point is about 140 ° C, so as to maintain a close relationship with the substrate. melting point. The specific raw material consumption is shown in Table 1 below.

[0063] First, the polypropylene resin is ground into powder by a grinder, and then added into a high-speed mixer in the order of polypropylene, inorganic silica, nucleating agent, erucamide or oleic acid amide and mixed evenly, and then added into a twin-screw extruder The machine carries out water-cooled strand cutting, the processing temperature is 180-200°C, not exceeding 200°C, and the screw spee...

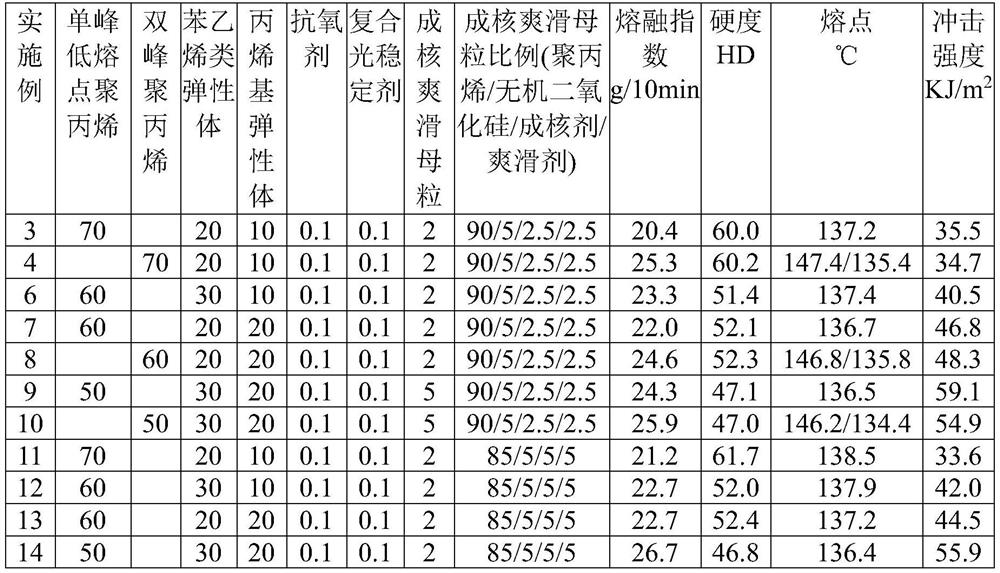

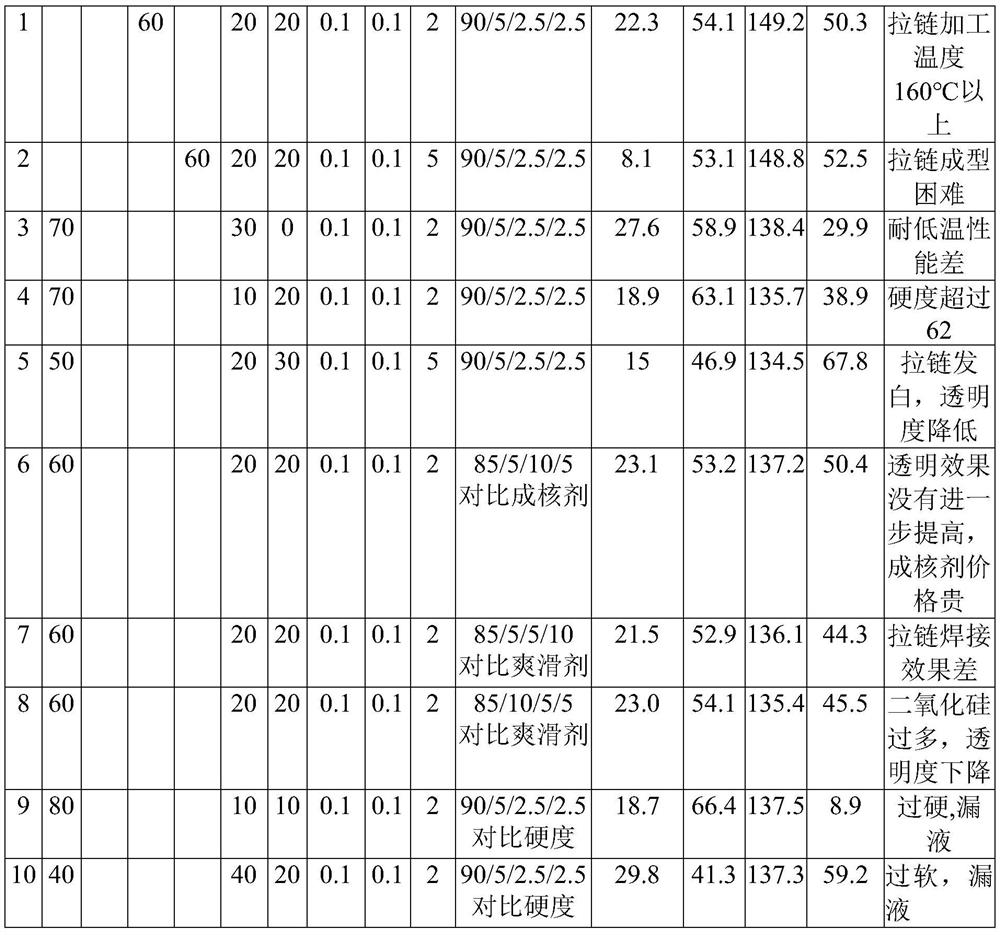

Embodiment 3-14

[0067] Prepare the modified polypropylene zipper material, comprising the following steps:

[0068] Add polypropylene, styrene-based elastomer, propylene-based elastomer, nucleated smooth masterbatch, antioxidant, and photosynthetic stabilizer in turn, mix in the color mixer for 3-5 minutes, mix well and add to the extruder, or Use an automatic feeding system to feed materials according to the ratio, extrude at a temperature of 160-200°C and a low torque speed of no more than 300rpm, water-cool, dry, and pelletize to obtain a modified polypropylene zipper material.

[0069] The formula components and dosage in each embodiment are shown in Table 2 below. The zipper is prepared by using the polypropylene zipper material prepared in each embodiment: the modified polypropylene zipper material is put into the feeding cylinder of the high-speed zipper extruder, and melted at high temperature , and then extruded through a die, and naturally cooled and shaped for more than 12 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com