Waterproof treatment technology of capacitive touch screen

A capacitive touch screen, waterproof treatment technology, applied in the direction of electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of easy water ingress and burnout, undurable battery, fragile screen, etc., and achieve waterproof The effect of good performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

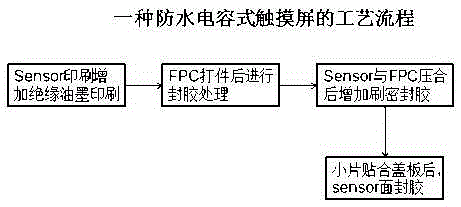

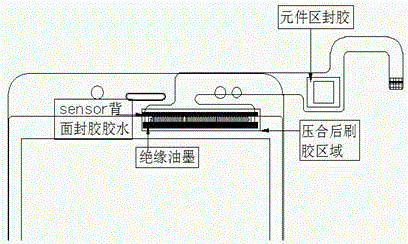

[0022] Such as figure 1 , figure 2 As shown, the steps include

[0023] 1) Functional film sensor printing adds insulating ink printing in the bonding area of thermal compression, and seals the excess part after the silver glue and OCA are bonded to ensure that it will not be oxidized and waterproof.

[0024] 2) The flexible circuit board FPC is subjected to glue dispensing, and the exposed pads of components such as ICs, capacitors, resistors, and diodes are sealed with glue. After this action, the sealing degree is 100% after the SMT of the flexible circuit board FPC board.

[0025] 3) After the functional chip sensor and the flexible circuit board FPC are hot-pressed, apply a layer of sealing glue on the connection area between the flexible circuit board FPC and the functional chip sensor on the pressing surface. This glue is insulating, transparent, durable, and its performance is guaranteed for 1 year. Above; the glue brushing area includes the entire FPC pressing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com