Method for machining elastic nuclear power jackets

A technology of elastic jacket and processing method, which is applied to the processing field of nuclear power elastic jacket, can solve the problems of insufficient shrinkage of inner holes at both ends, affecting the working effect, poor elasticity of components, etc., and achieves high elasticity, high manufacturing precision, The effect that meets the design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

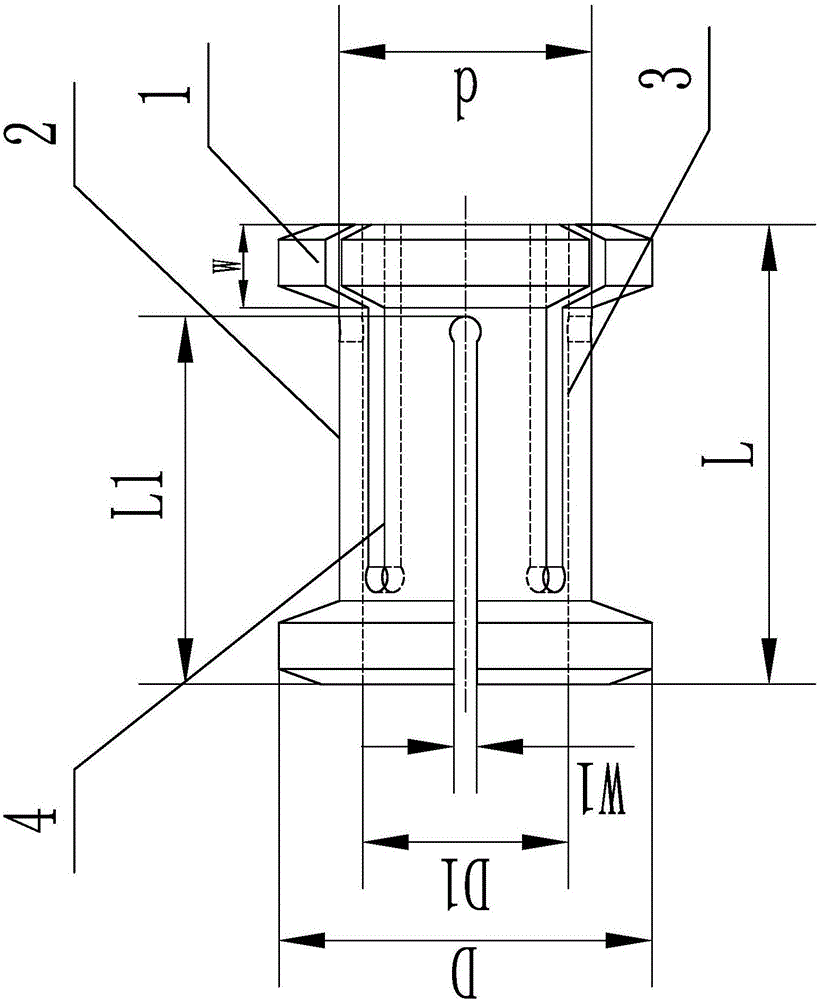

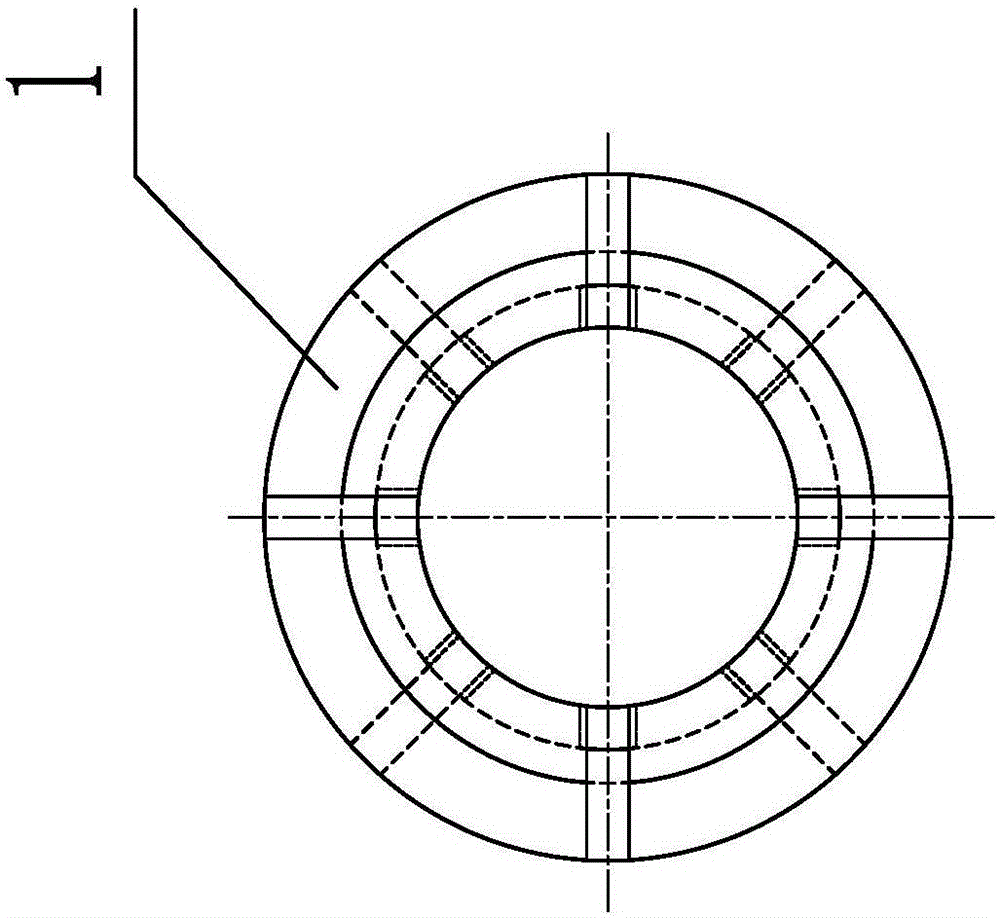

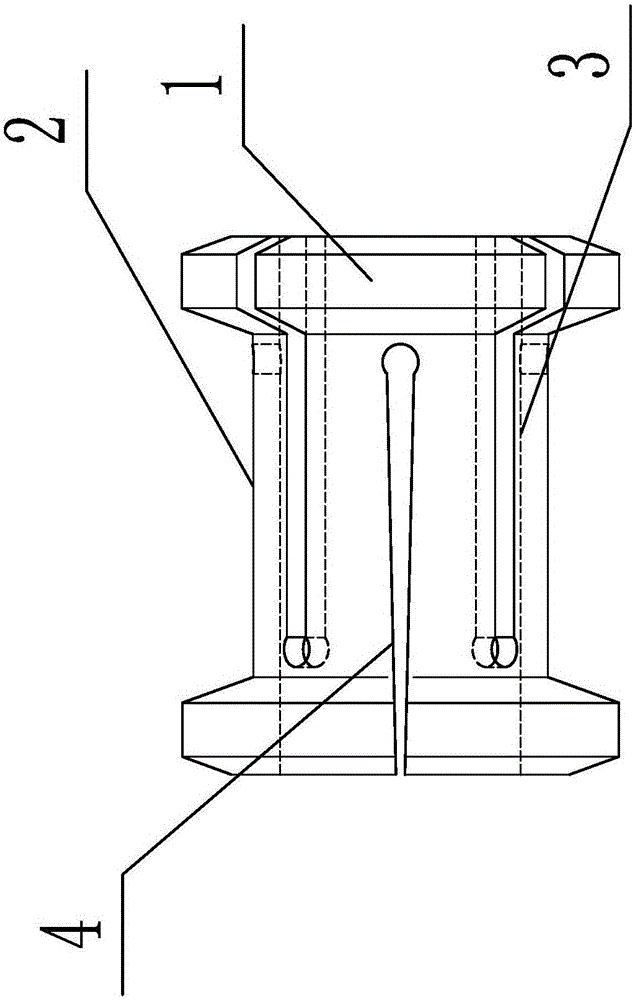

[0019] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, the processing method of a kind of nuclear power elastic jacket described in this embodiment, described method is to realize according to the following steps:

[0020] Step 1: Prepare materials: prepare cylindrical steel material, the diameter of the steel material is 26mm, and the length of the steel material is 32mm;

[0021] Step 2: Rough turning: place the steel material on a CNC lathe and turn it into a circular sleeve according to the drawings. The diameter of the outer circle of the steel material after turning is 25mm, the diameter of the inner hole of the steel material after turning is 13mm, and the length of the steel material after turning L is 30mm, and an annular groove is processed radially on the outer surface of the circular sleeve body. The depth of the annular groove is 4mm, and the groove width of the annular groove is 18mm. The speed of the CNC lathe is 600r / min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com