Polyurethane elastomer sealing process of waterproof zipper tape

A polyurethane elastomer, waterproof zipper technology, applied in the chain field, can solve the problems of not achieving the anti-seepage effect, the cloth strip is easy to be stuck on the chain teeth, and the use experience is not good, so as to improve the embedded stability, improve the waterproof, The effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

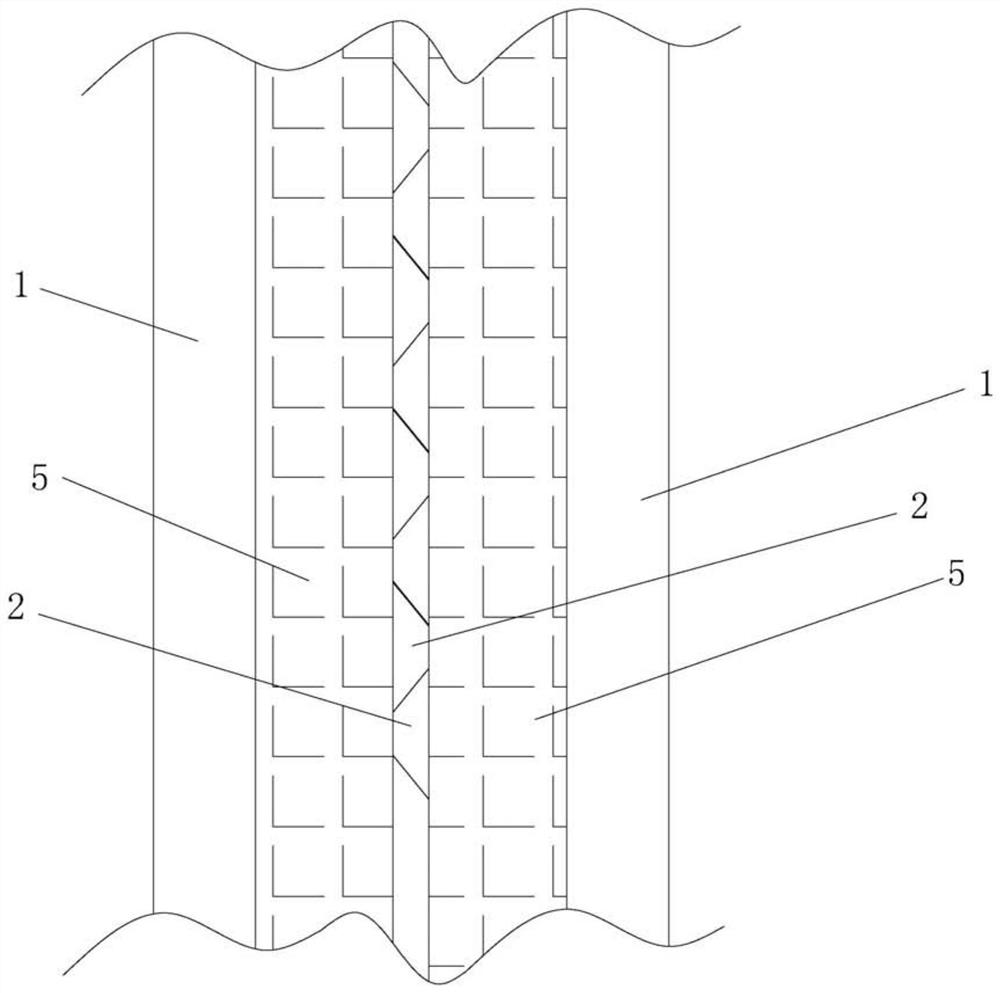

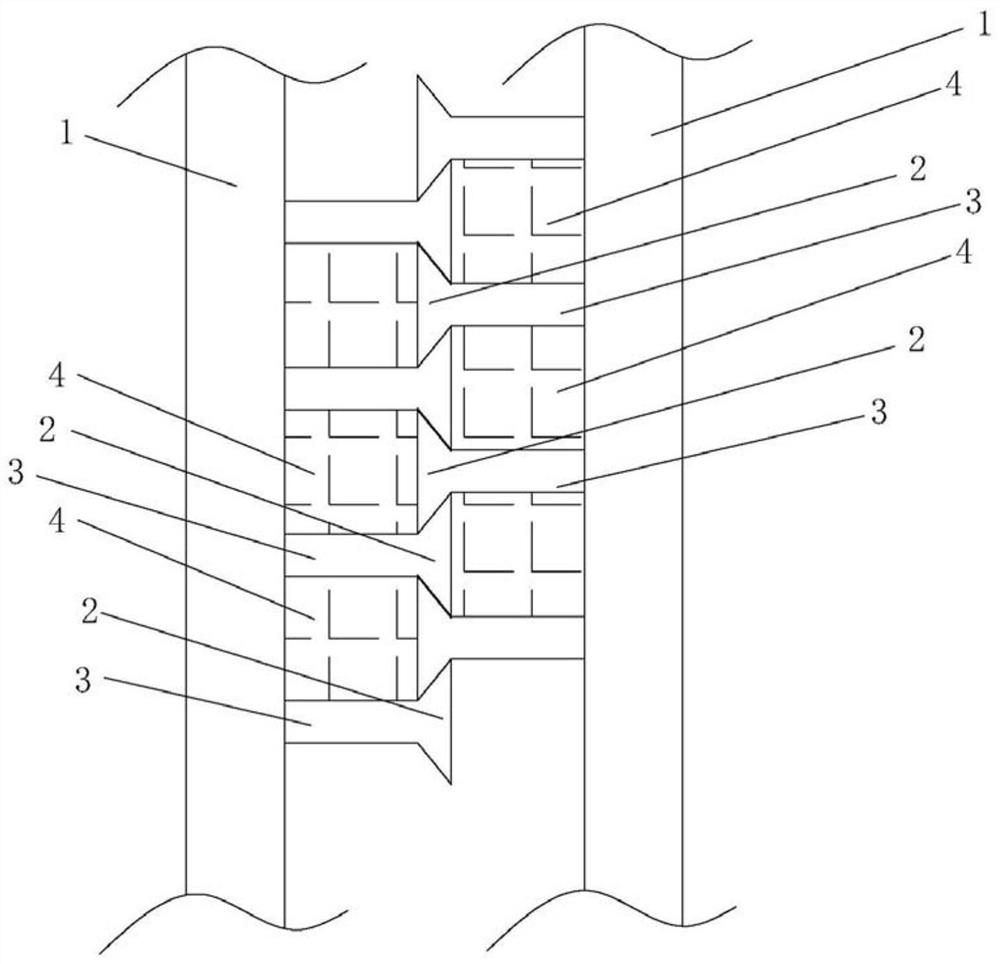

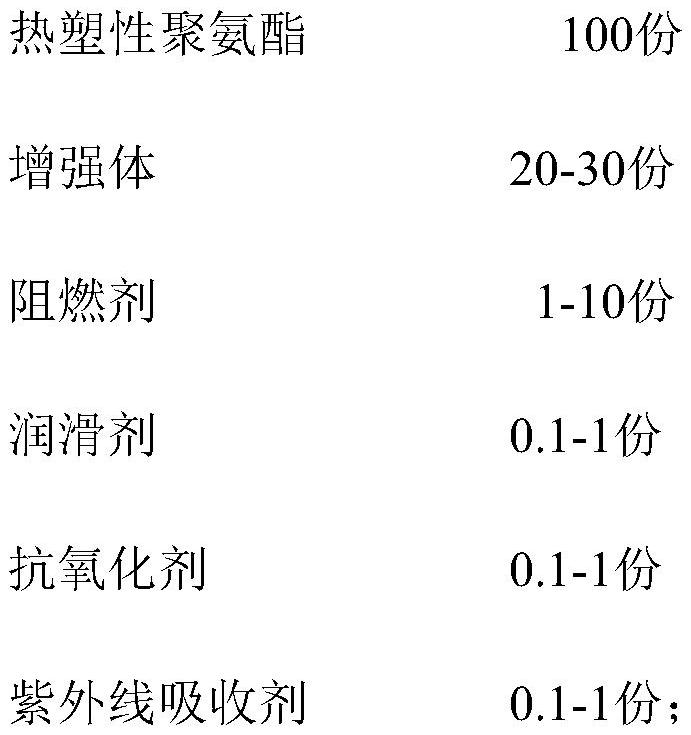

[0030] A polyurethane elastomer sealing process for a waterproof chain. The waterproof zipper includes two zipper tapes 1. Several chain teeth are arranged on the sides of the zipper tape 1. The chain teeth include tooth roots 3 and are arranged on the teeth. tooth head 2 on the outside of the root 3, the tooth heads 2 of the two zipper tapes 1 mesh with each other, the space between the tooth roots 3 is filled with the first resin body 4, the upper surface of the tooth root 3, the teeth The lower surface of the root 3, the upper surface of the first resin body 4, and the lower surface of the first resin body 4 are compounded with a second resin body 5, and the first resin body 4 and the second resin body 5 are integrated through an injection molding sealing process Molding, the first resin body 4 and the second resin body 5 are both polyurethane elastomers, and the injection molding sealing process includes the following steps: placing the zipper tape 1 with a toothed chain in...

Embodiment 2

[0046] A polyurethane elastomer sealing process for a waterproof chain. The waterproof zipper includes two zipper tapes 1. Several chain teeth are arranged on the sides of the zipper tape 1. The chain teeth include tooth roots 3 and are arranged on the teeth. tooth head 2 on the outside of the root 3, the tooth heads 2 of the two zipper tapes 1 mesh with each other, the space between the tooth roots 3 is filled with the first resin body 4, the upper surface of the tooth root 3, the teeth The lower surface of the root 3, the upper surface of the first resin body 4, and the lower surface of the first resin body 4 are compounded with a second resin body 5, and the first resin body 4 and the second resin body 5 are integrated through an injection molding sealing process Molding, the first resin body 4 and the second resin body 5 are both polyurethane elastomers, and the injection molding sealing process includes the following steps: placing the zipper tape 1 with a toothed chain in...

Embodiment 3

[0062] A polyurethane elastomer sealing process for a waterproof chain. The waterproof zipper includes two zipper tapes 1. Several chain teeth are arranged on the sides of the zipper tape 1. The chain teeth include tooth roots 3 and are arranged on the teeth. tooth head 2 on the outside of the root 3, the tooth heads 2 of the two zipper tapes 1 mesh with each other, the space between the tooth roots 3 is filled with the first resin body 4, the upper surface of the tooth root 3, the teeth The lower surface of the root 3, the upper surface of the first resin body 4, and the lower surface of the first resin body 4 are compounded with a second resin body 5, and the first resin body 4 and the second resin body 5 are integrated through an injection molding sealing process Molding, the first resin body 4 and the second resin body 5 are both polyurethane elastomers, and the injection molding sealing process includes the following steps: placing the zipper tape 1 with a toothed chain in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com