Silica gel sealing process of waterproof chain

A waterproof zipper and silica gel technology, which is applied in the field of chains, can solve the problems of not achieving anti-seepage effect, not being able to achieve waterproof, and not having a high user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

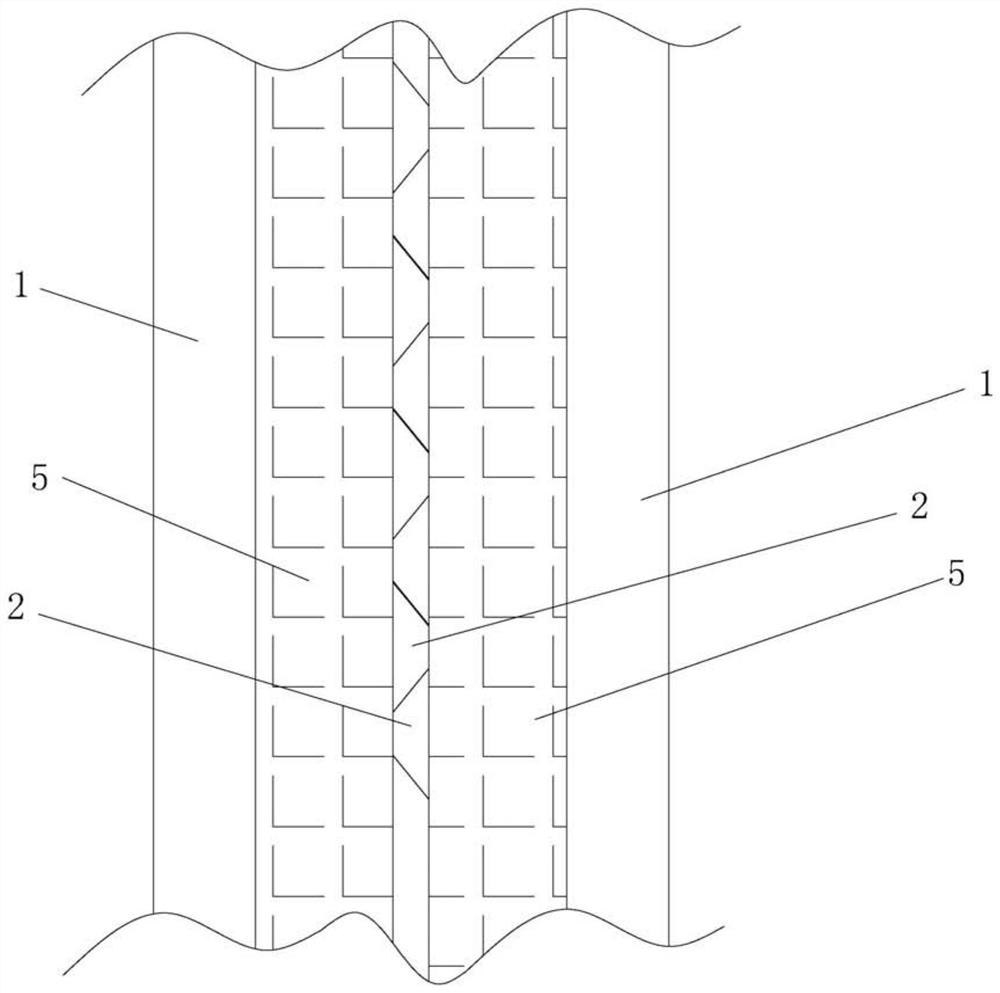

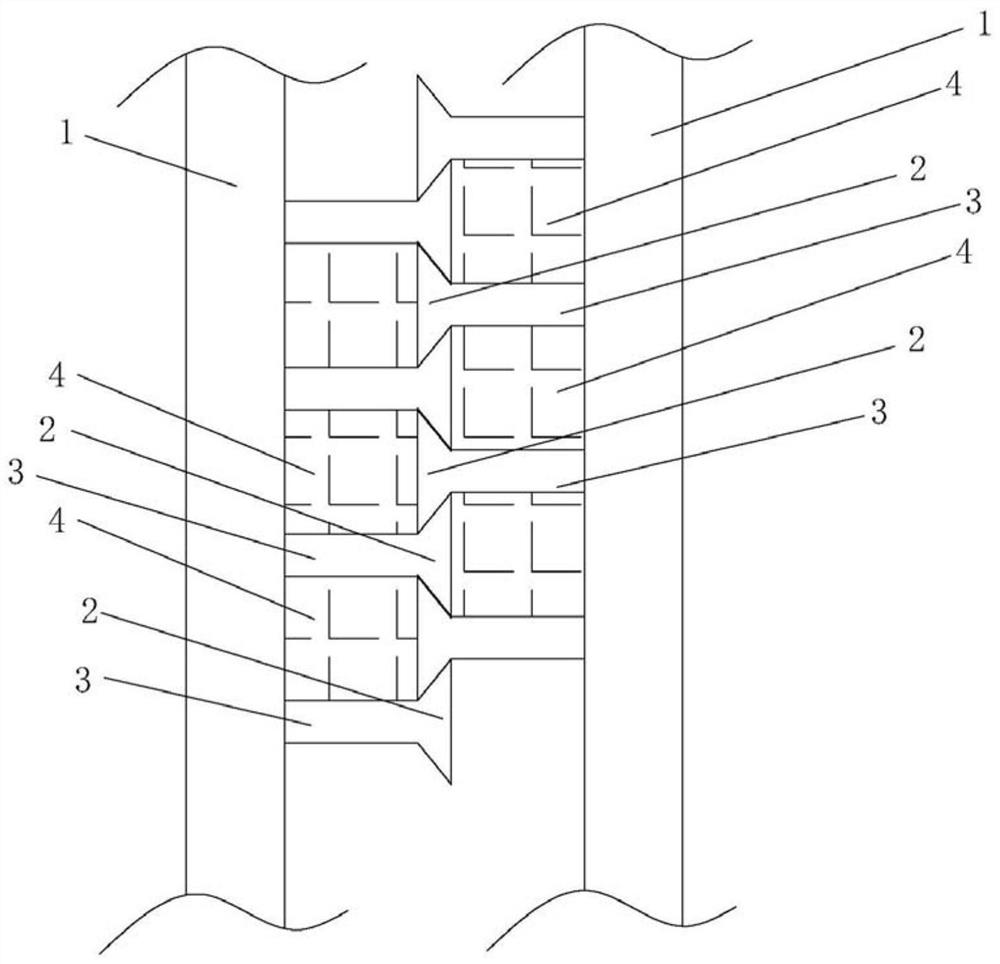

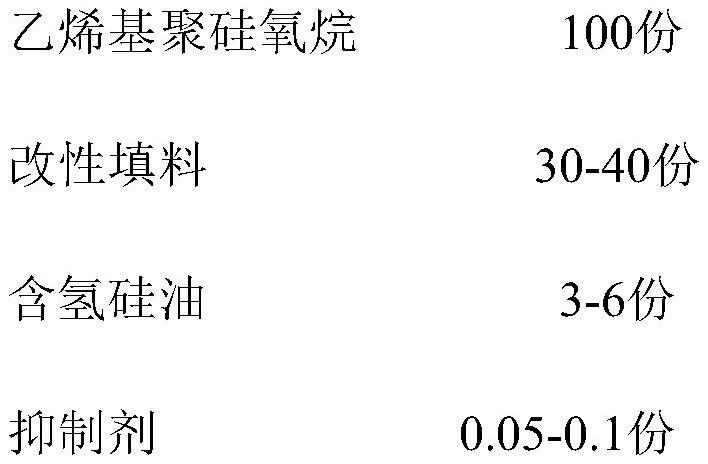

[0035] A silicone sealing process for a waterproof chain. The waterproof zipper includes two zipper tapes 1. Several chain teeth are arranged on the sides of the zipper tape 1. The chain teeth include a tooth root 3 and a tooth root 3. The tooth heads 2 on the outside, the tooth heads 2 of the two zipper tapes 1 mesh with each other, the space between the tooth roots 3 is filled with the first resin body 4, the upper surface of the tooth roots 3, the tooth roots 3 The lower surface of the lower surface, the upper surface of the first resin body 4 and the lower surface of the first resin body 4 are compounded with a second resin body 5, and the first resin body 4 and the second resin body 5 are integrally formed by an injection molding sealing process, Both the first resin body 4 and the second resin body 5 are silica gel, and the injection molding sealing process includes the following steps: placing the zipper tape 1 with the tooth chain in an injection mold, and performing in...

Embodiment 2

[0055] A silicone sealing process for a waterproof chain. The waterproof zipper includes two zipper tapes 1. Several chain teeth are arranged on the sides of the zipper tape 1. The chain teeth include a tooth root 3 and a tooth root 3. The tooth heads 2 on the outside, the tooth heads 2 of the two zipper tapes 1 mesh with each other, the space between the tooth roots 3 is filled with the first resin body 4, the upper surface of the tooth roots 3, the tooth roots 3 The lower surface of the lower surface, the upper surface of the first resin body 4 and the lower surface of the first resin body 4 are compounded with a second resin body 5, and the first resin body 4 and the second resin body 5 are integrally formed by an injection molding sealing process, Both the first resin body 4 and the second resin body 5 are silica gel, and the injection molding sealing process includes the following steps: placing the zipper tape 1 with the tooth chain in an injection mold, and performing in...

Embodiment 3

[0075] A silicone sealing process for a waterproof chain. The waterproof zipper includes two zipper tapes 1. Several chain teeth are arranged on the sides of the zipper tape 1. The chain teeth include a tooth root 3 and a tooth root 3. The tooth heads 2 on the outside, the tooth heads 2 of the two zipper tapes 1 mesh with each other, the space between the tooth roots 3 is filled with the first resin body 4, the upper surface of the tooth roots 3, the tooth roots 3 The lower surface of the lower surface, the upper surface of the first resin body 4 and the lower surface of the first resin body 4 are compounded with a second resin body 5, and the first resin body 4 and the second resin body 5 are integrally formed by an injection molding sealing process, Both the first resin body 4 and the second resin body 5 are silica gel, and the injection molding sealing process includes the following steps: placing the zipper tape 1 with the tooth chain in an injection mold, and performing in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com