Ink piezoelectric control system and ink piezoelectric control optimization method capable of improving printing precision

A technology of control system and optimization method, applied in printing and other directions, can solve problems such as the inability to automatically eliminate satellite droplets, and achieve the effect of stable image frame rate, wide application range and fast air pressure adjustment speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

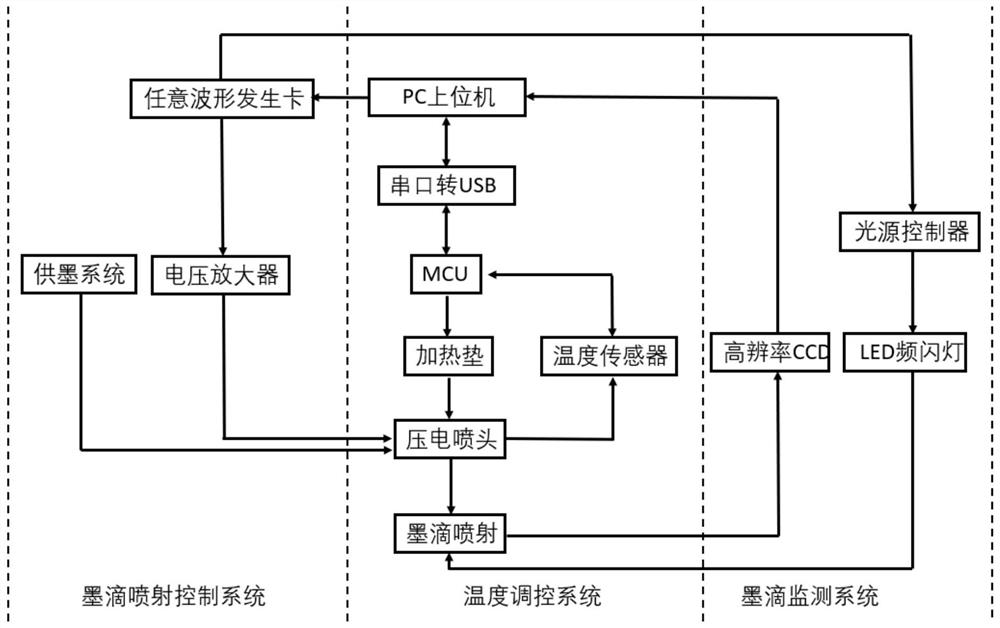

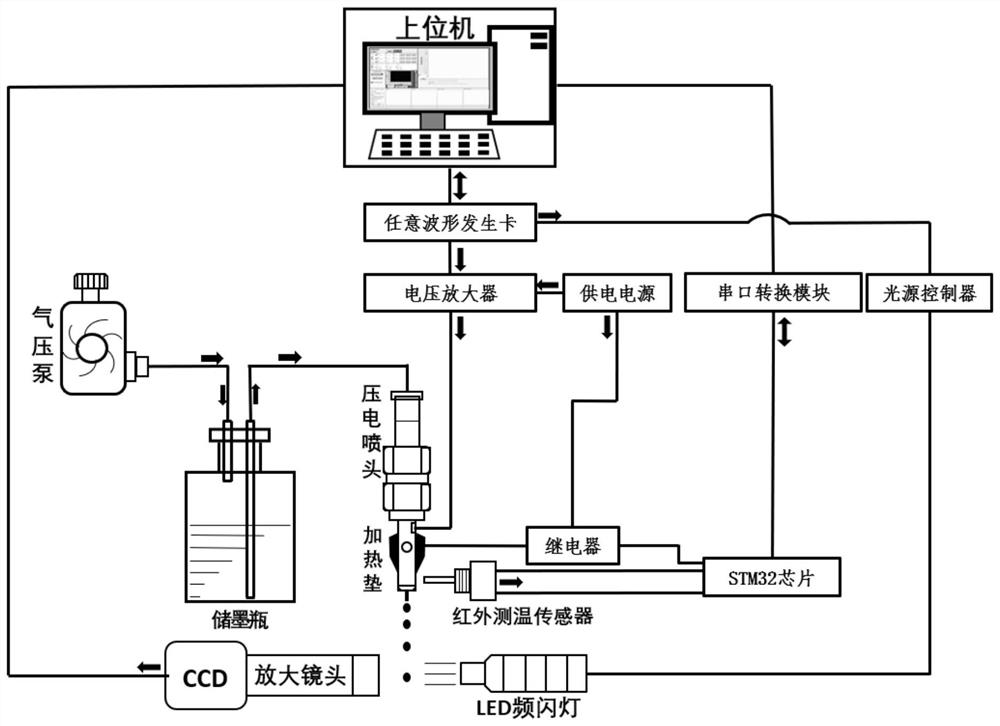

[0046] This embodiment provides an ink piezoelectric control system that can improve printing accuracy, such as figure 1 and figure 2 As shown, it includes a host computer, an ink droplet ejection control system, an ink droplet monitoring system and a temperature control system. The ink droplet ejection control system includes an ink supply module, a piezoelectric drive module and a piezoelectric nozzle. control module, temperature acquisition module and temperature regulation module.

[0047] Wherein, the ink supply module and the piezoelectric driving module are respectively connected to the piezoelectric nozzle, and the piezoelectric driving module is connected to the host computer, and receives instructions from the host computer to control the piezoelectric nozzle to eject ink droplets.

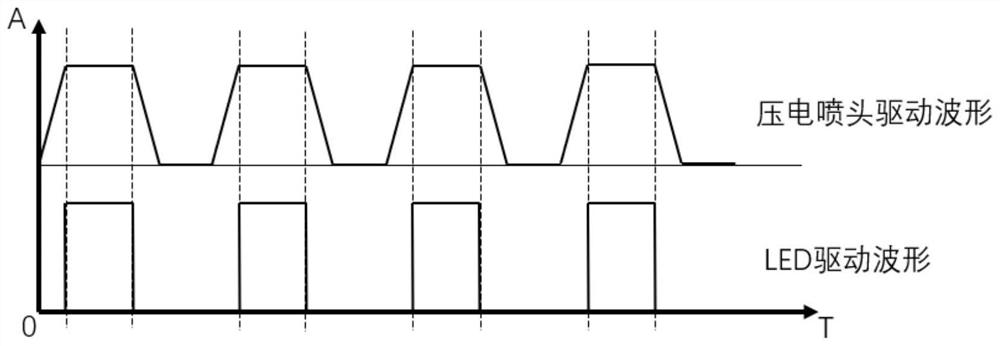

[0048] The ink drop monitoring system is connected to the host computer, and the ink drop monitoring system continuously collects multiple images during the ink drop falling process an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com