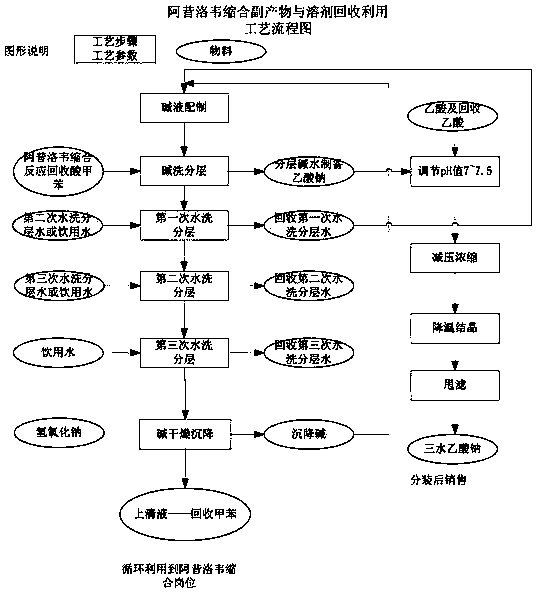

Method for recycling acyclovir condensation by-products and solvents

A technology of by-products and solvents, which is applied in the field of recovery and utilization of acyclovir condensation reaction by-products and reaction solvents, can solve the problems of high consumption of sodium hydroxide, consumption of steam and electric energy, and high processing costs, so as to reduce consumption and facilitate Effects of preparation and elimination of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After drying the toluene, the sodium hydroxide (containing 150 kg of sodium hydroxide) settled at the bottom of the kettle was added to 800 L of the reclaimed water separated from the first batch of acid toluene washed with water for the first time to prepare a 15-20% sodium hydroxide solution. 3000L of acyclovir condensation reaction recovered acid toluene, stirred and neutralized for 50 minutes, allowed to stand for 40 minutes to separate layers, took the lower layer liquid and measured the pH value of 9.5 with extensive pH test paper, and separated the lower layer of saline phase 840L.

[0022] Add 800 L of reclaimed water separated from the second batch of acid toluene to the supernatant toluene, stir and wash for 30 minutes, let the layers stand for 30 minutes, and separate the lower aqueous phase. Add 800 L of reclaimed water separated from the previous batch of acid toluene to the supernatant liquid toluene for the third time washing and layering, stir and wash fo...

Embodiment 2

[0026] After drying the toluene, the sodium hydroxide (containing 150 kg of sodium hydroxide) settled at the bottom of the kettle was added to 800 L of the reclaimed water separated from the first batch of acid toluene washed with water for the first time to prepare a 15-20% sodium hydroxide solution. 3000L of acyclovir condensation reaction recovered acid toluene, stirred and neutralized for 40 minutes, allowed to stand for 30 minutes to separate layers, took the lower layer liquid and measured the pH value of 9.5 with extensive pH test paper, and separated the lower layer of saline phase 860L.

[0027] Add 800 L of recovered water separated from the second batch of acid toluene to the supernatant liquid toluene, stir and wash for 20 minutes, let stand for 20 minutes to separate the layers, and separate the lower aqueous phase. Add 800 L of reclaimed water separated from the third water washing and layering of the previous batch of acid toluene to the supernatant liquid toluen...

Embodiment 3

[0031] After drying the toluene, the sodium hydroxide (containing 150 kg of sodium hydroxide) that settled at the bottom of the kettle was added to 800 L of the recovered water separated from the first batch of acid toluene washed with water for the first time to prepare a 15-20% sodium hydroxide solution. 3000L of acyclovir condensation reaction recovered acid toluene, stirred and neutralized for 30 minutes, left to separate layers for 30 minutes, took the lower layer liquid and measured the pH value of 10 with extensive pH test paper, and separated the lower layer of saline phase 865L.

[0032] Add 800 L of reclaimed water separated from the second batch of acid toluene to the supernatant liquid toluene, stir and wash for 25 minutes, let the layers stand for 25 minutes, and separate the lower aqueous phase. Add 800 L of reclaimed water separated from the third water washing and layering of the previous batch of acid toluene to the supernatant liquid toluene, stir and wash for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com