Flue gas desulfurization, purification and recovery process for flue gas desulfurization column

A desulfurization tower and flue gas technology, applied in gas treatment, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of full contact, large adsorbent consumption, high equipment manufacturing cost, etc., to reduce the possibility of clogging equipment, Reduce cleaning difficulty and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

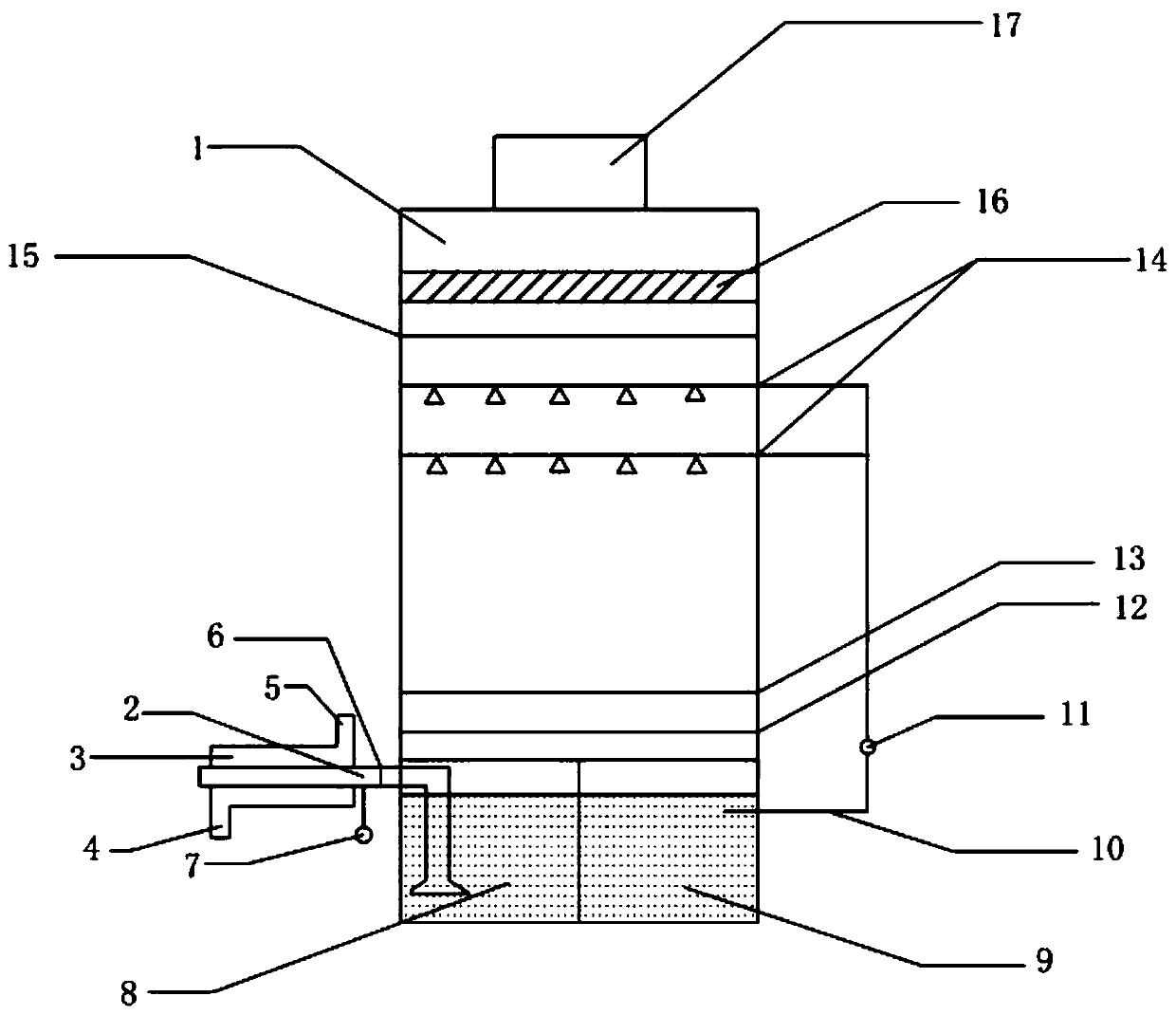

[0046] A flue gas desulfurization purification recovery process for a flue gas desulfurization tower, the flue gas desulfurization purification recovery process comprises the following steps:

[0047] Step S1: Turn on the circulating pump 11, so that the alkaline liquid in the circulating liquid pool 8 enters the conduit 10, transports it to the spray layer 14, opens the nozzle of the spray layer 14, and sprays out the atomized alkaline liquid;

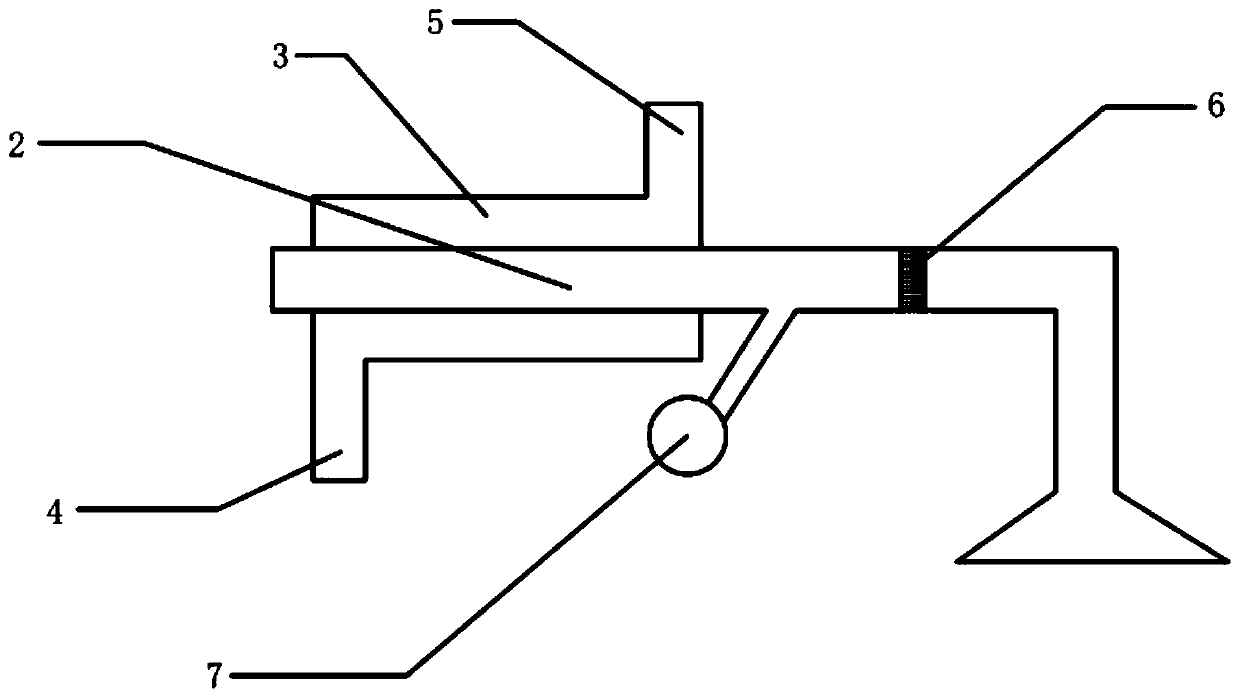

[0048] Step S2: Pass the cold fluid into the refrigerant inlet 4 and flow out from the refrigerant outlet 5, turn on the blower 7 of the flue gas inlet 2, pressurize the flue gas so that the speed of the flue gas reaches 5m / s, and move the flue gas along the inlet The smoke port 2 passes through the first filter screen 6 and enters the bottom of the gas absorption pool 8 equipped with alkaline liquid, and part of the sulfur-containing substances in the flue gas fully reacts with the alkaline solution in the gas absorption pool 8 to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com