High performance. Energy saving, environmental protective heat storage type refinery furnace for metal magnesium

A high-efficiency energy-saving and environment-friendly technology, applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of uneven service life of refining pots, inflexible combustion temperature control, low coal combustion efficiency, etc., and achieve high Pollution problem, unique combustion method, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

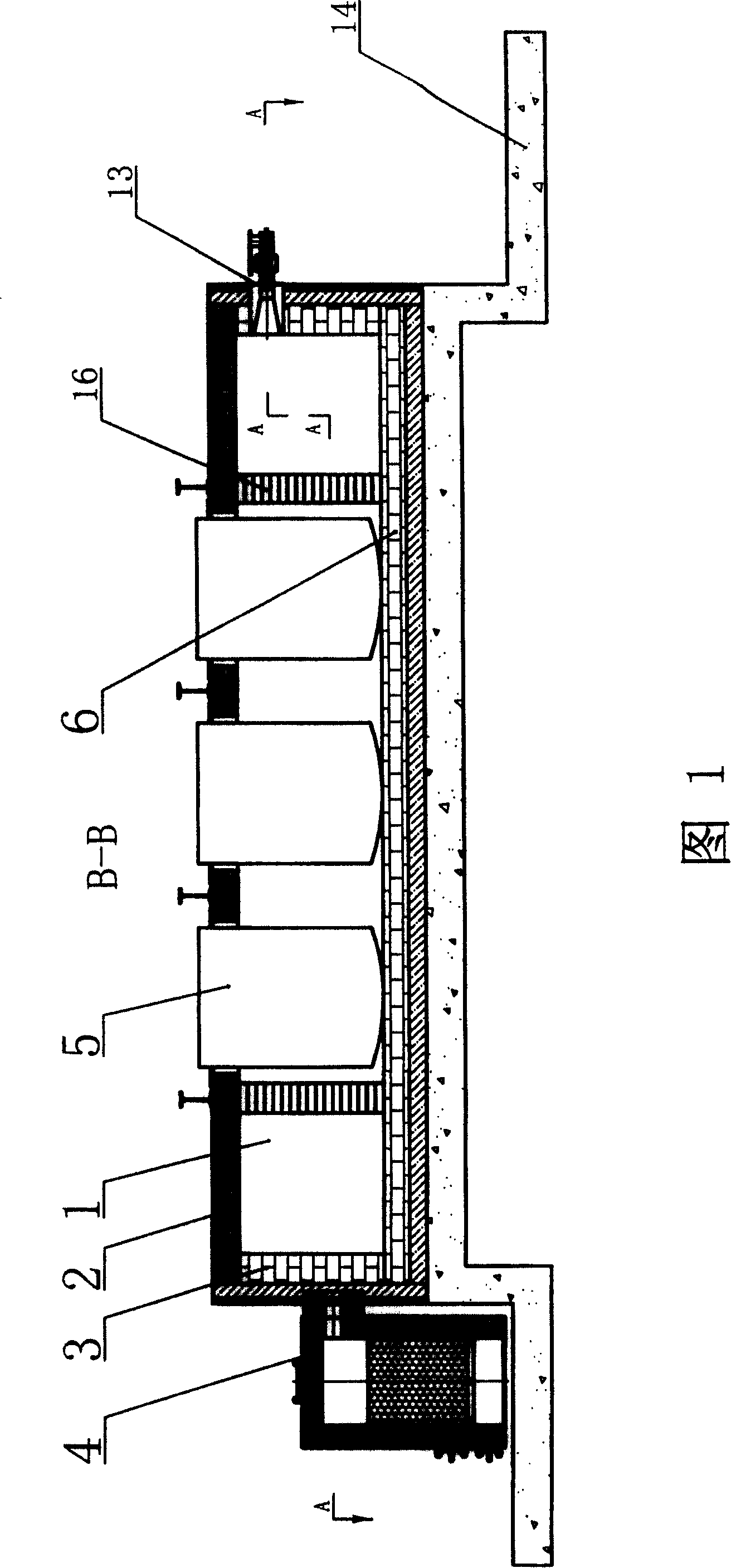

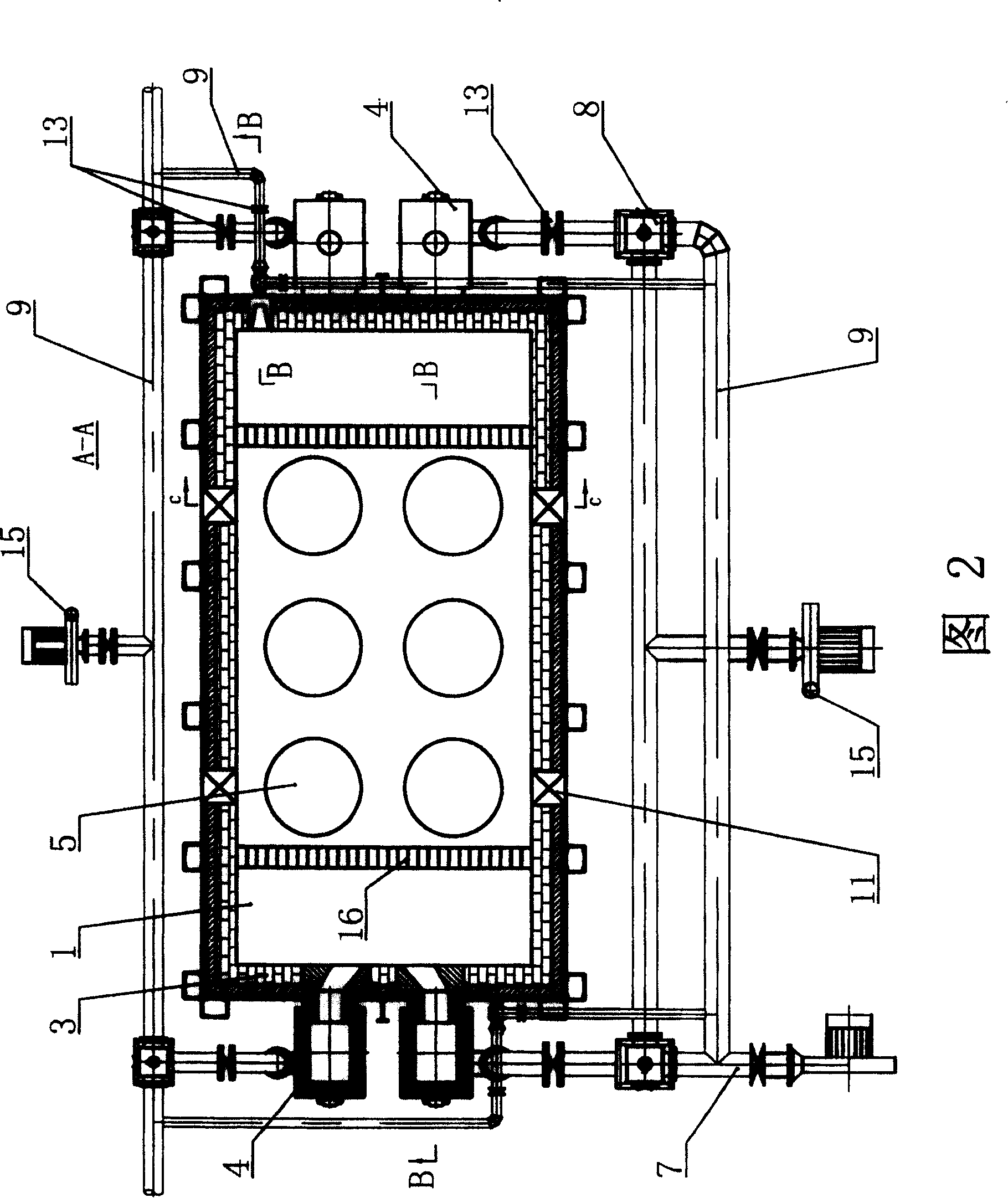

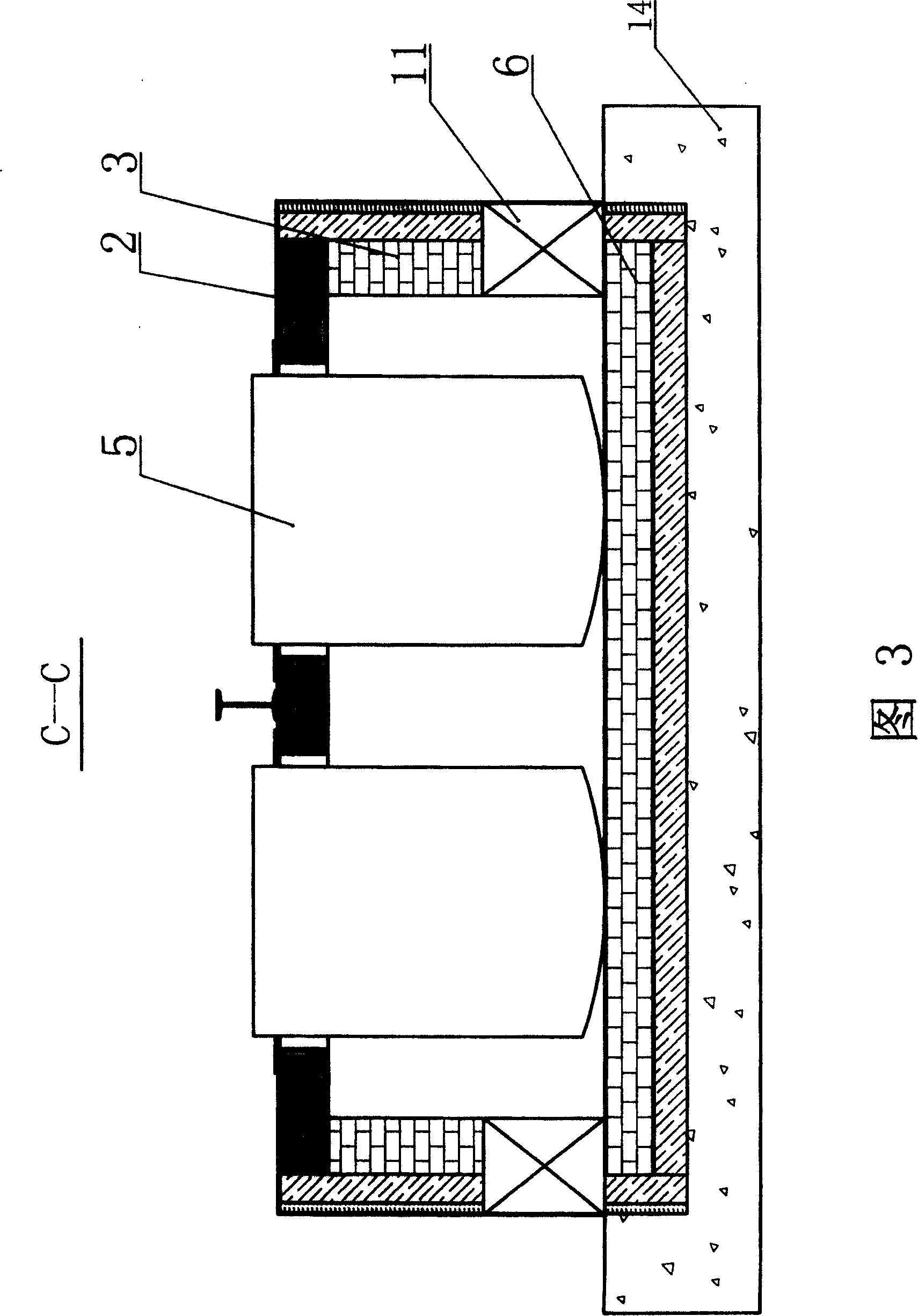

[0026] See Figure 1~ Figure 5 , The present invention includes furnace 1, furnace roof 2, furnace wall 3, burner 4, refining pot 5, furnace bottom 6 and blast system 7. There are several pairs of double regenerative burners 4 correspondingly arranged at the bottom of the furnace wall 3 at both ends along the furnace width direction, and a reversing valve 8 is installed on the furnace walls 3 at both ends, and the reversing valve 8 and the regenerative burner 4 It is connected with the blast system 7 through the pipeline 9 outside the furnace and the reversing control system 10. The refining pots 5 in the furnace 1 are arranged vertically. The opening of the refining pots is on the top of the furnace. The refining pots 5 in the furnace 1 are divided into There are several rows, each row of tanks is spaced at a certain distance, and each row of refining pots 5 is several, and the specific number is determined according to the process requirements. Mouth 4, two ignition burners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com