Anisotropic conductive film containing benzoxazine and preparation method of anisotropic conductive film

A technology of anisotropic conductive film and anisotropic conductive adhesive, which is applied in the field of anisotropic conductive film containing benzoxazine and its preparation, can solve the problems of shortened service life, aging resistance, cured product damage, etc. Achieve the effect of good compactness, good moisture resistance and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of the above-mentioned anisotropic conductive film containing benzoxazine comprises the following steps:

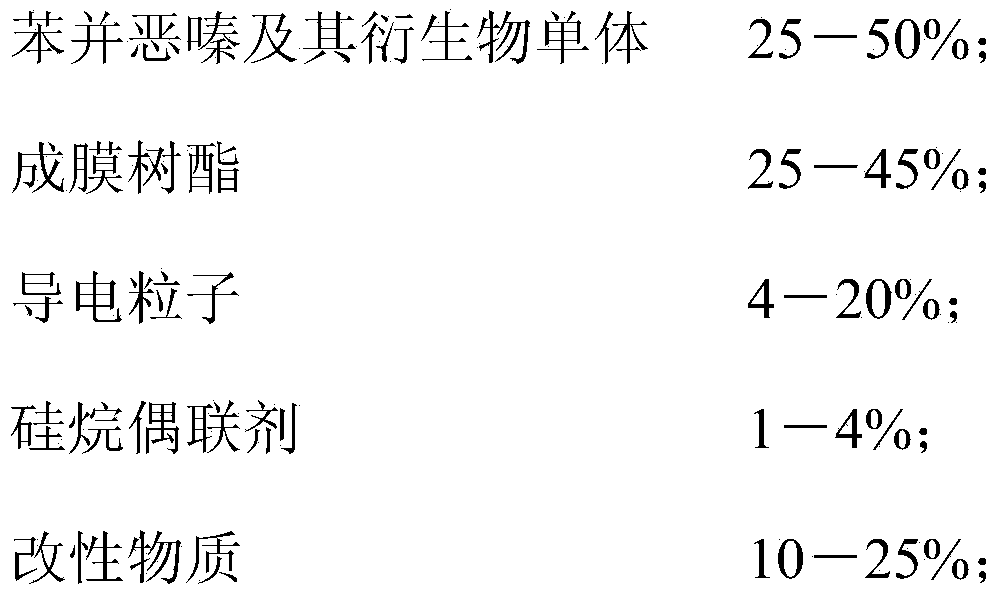

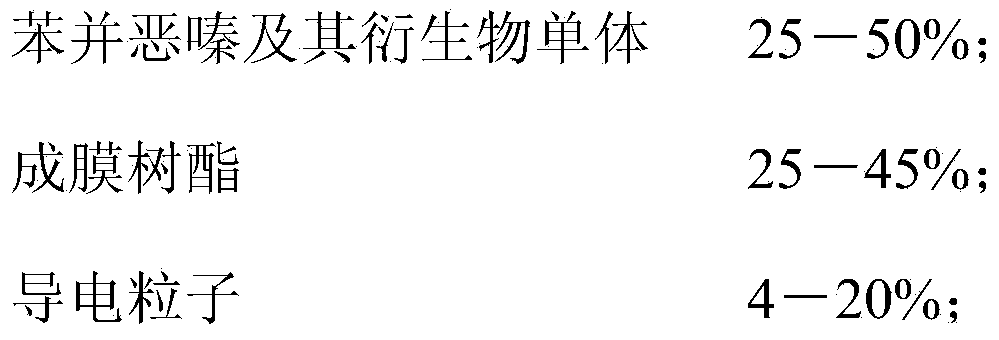

[0065] Step 1: Prepare anisotropic conductive adhesive: first weigh 25-50% of benzoxazine and its derivative monomer, 25-45% of film-forming resin, 10-25% of modified substance and solvent into the glue tank , start the stirrer, the speed is 300-800rpm, heat up to 40°C-60°C, after the substance is dissolved and stirred, cool down to room temperature;

[0066] The above-mentioned solvent is formed by mixing toluene and ethyl acetate at a volume ratio of 1:0.4. The weight ratio of the solvent obtained by mixing the above-mentioned benzoxazine and its derivative monomers, film-forming resins, and modified substances is ( 0.8-1.2): 1;

[0067] Weigh 4-20% of the conductive particles and add them to the glue solution obtained above, and stir ultrasonically for 1 hour at a speed of 500 rpm (cool down in time to keep the temperature below 60°C). Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com