Multi-area intelligent online optimizing control method for thermal efficiency of heating furnace

A technology for optimizing control and heating furnaces, applied in furnace control devices, lighting and heating equipment, furnaces, etc., and can solve problems such as unsuitable continuous adjustment, large dead zone, and inability to talk about thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

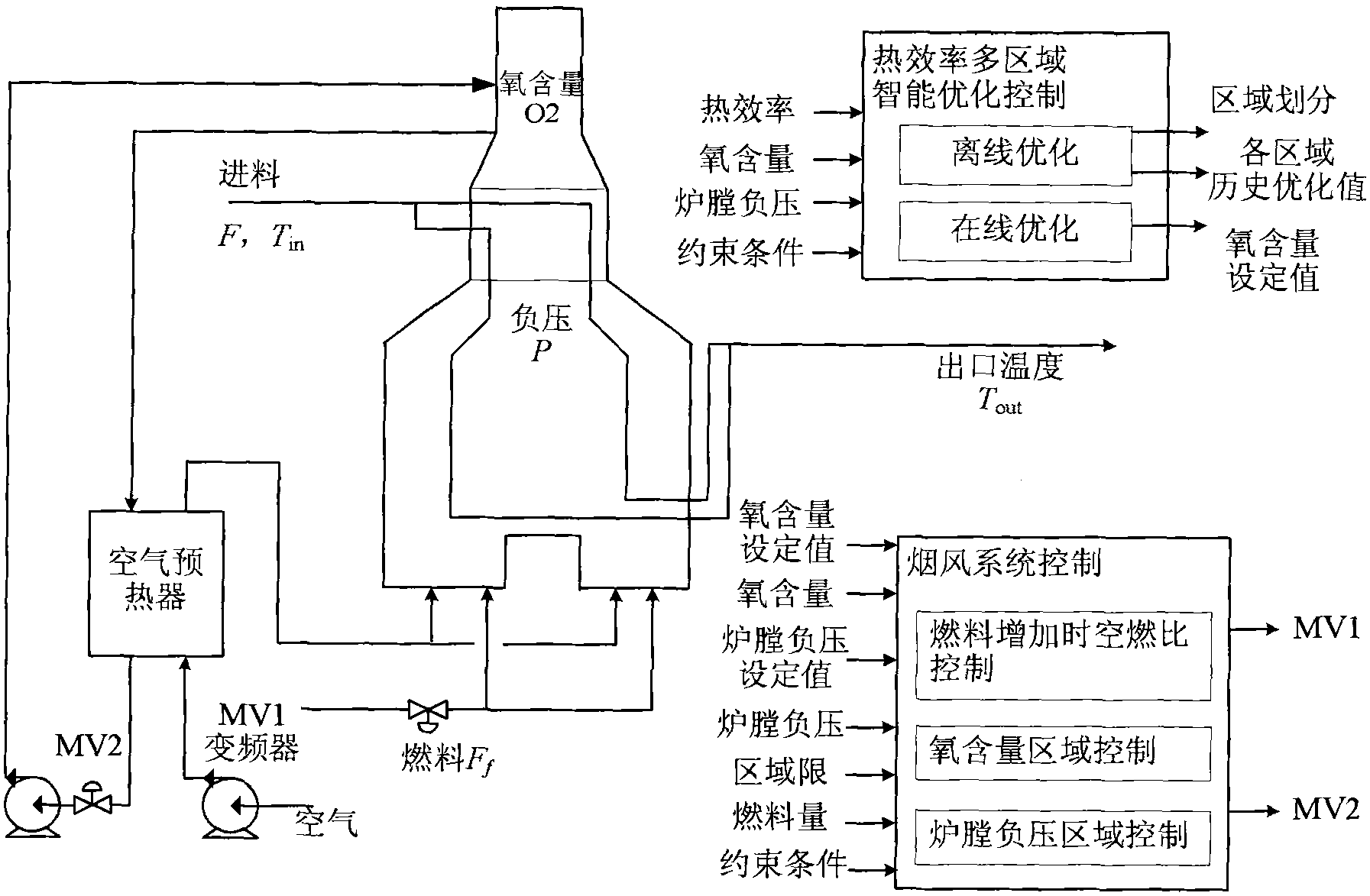

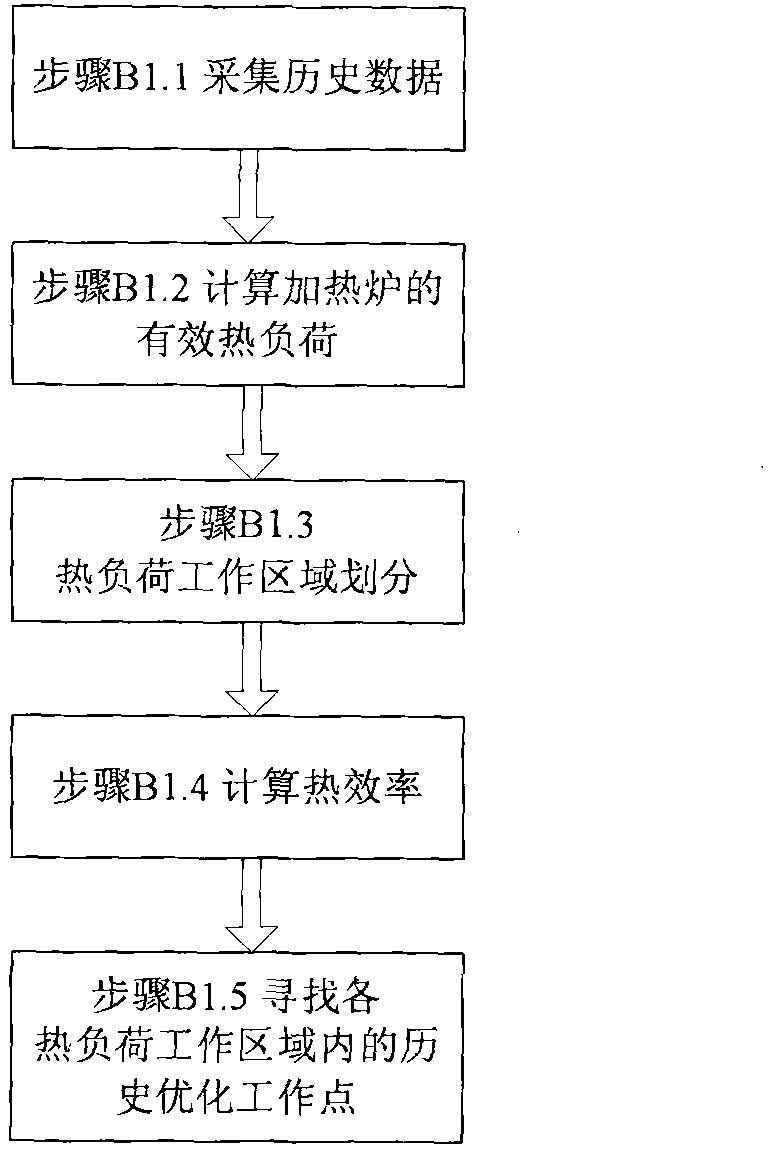

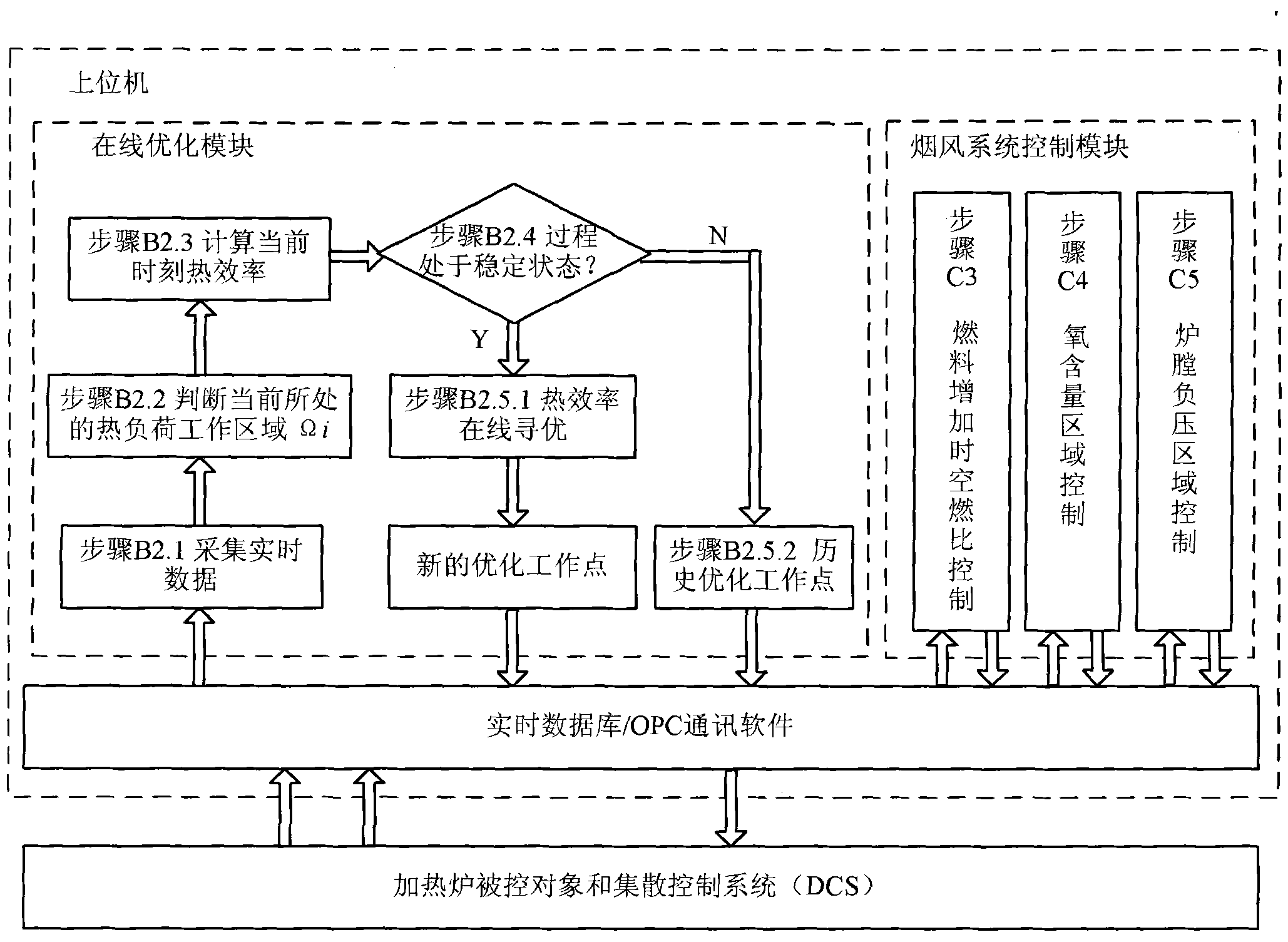

[0120] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples of implementation. in, figure 1 It is a schematic diagram of the multi-region intelligent optimization control structure of the heating furnace process and thermal efficiency; figure 2 It is a schematic diagram of the off-line part of thermal efficiency optimization; image 3 It is a schematic diagram of the overall steps of thermal efficiency optimization online optimization and flue gas system control; Figure 4 is the heat efficiency optimized heat load zone classifier; Figure 5 It is the flow chart of thermal efficiency online optimization program.

[0121] Thermal efficiency offline optimization

[0122] Step B1.1: Step test to obtain steady-state response time for thermal efficiency:

[0123] When the process is stable, apply a step test signal to the set value of oxygen content, record the thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com