Method for coating dopamine on surface of ultrasonic reinforced material

A technology for surface coating and reinforcing materials, which is applied in the direction of surface coating liquid devices, coatings, liquid injection devices, etc., and can solve problems such as poor coating uniformity, affecting surface modification quality, and poor coating strength , to achieve the effect of strong coating adhesion, shortening modification time and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

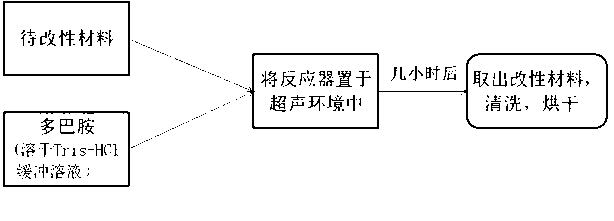

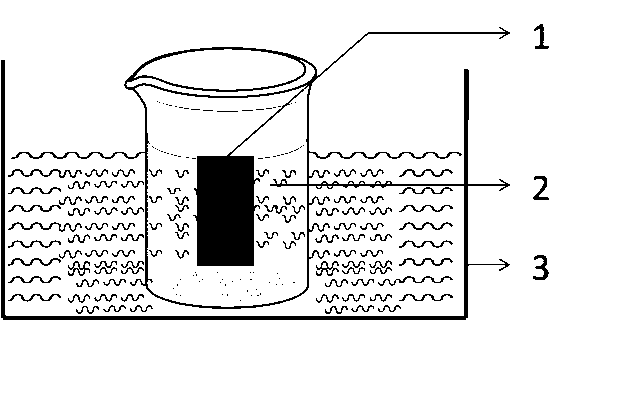

Method used

Image

Examples

Embodiment 1

[0026] (1) Alkaline buffer solution: Tris-0.1g; H 2 O-80ml; hydrochloric acid solution-0.1mol / L; pH=7.5;

[0027] (2) Dopamine modified solution: 2mg / ml

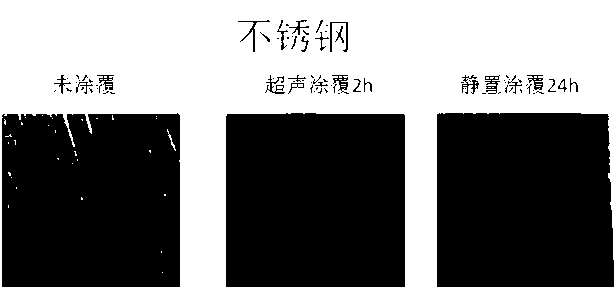

[0028] (3) Sample to be modified: 304 stainless steel

[0029] Such as image 3 and Figure 4 It can be seen that the surface of the sample coated by ultrasonic coating for 2 hours is more hydrophilic than the sample coated by static coating for 24 hours, and the surface of stainless steel coated by ultrasonic is more glossy, and the coating is denser and smoother.

Embodiment 2

[0031] (1) Alkaline buffer solution: Tris-0.2g; H 2 O-100ml; hydrochloric acid solution-1mol / L; pH=9.5;

[0032] (2) Dopamine modified solution: 6mg / ml

[0033] (3) Sample to be modified: glass slide

[0034] Such as Figure 5 and Figure 6 It can be seen that the hydrophilicity of the surface of the sample coated by ultrasonic coating for 2 hours and static coating for 24 hours is similar, and the coating of the ultrasonic coated glass slide is denser, smoother and more uniform.

Embodiment 3

[0036] (1) Alkaline buffer solution: Tris-0.121g; H 2 O-90ml; hydrochloric acid solution-0.2mol / L; pH=8.5;

[0037] (2) Dopamine modified solution: 3mg / ml

[0038] (3) Sample to be modified: plastic PET

[0039] Such as Figure 7 and Figure 8 It can be seen that the hydrophilicity of the surface of the sample coated by ultrasonic coating for 2 hours is better than that of the sample coated by static coating for 24 hours, and the coating of the ultrasonic coated glass slide is denser, smoother and more uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com