Method for preparing insulation bricks by using ramie fiber and riverway sludge

A technology of ramie fiber and river silt, applied in the field of building materials, can solve the problem of low strength, and achieve the effects of improving compressive performance, reducing costs, and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

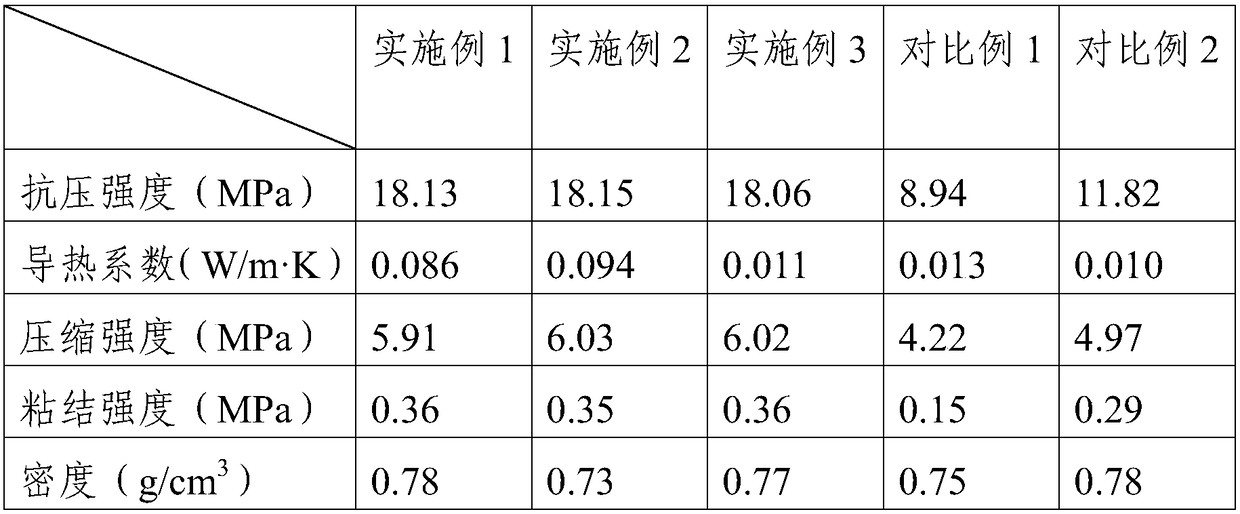

Examples

Embodiment 1

[0033] A kind of method utilizing ramie fiber and river silt to prepare insulation brick, comprises the following steps:

[0034] Dry the ramie and cut it to 15 mm, soak it in water for 55 minutes, knock the ramie 6-7 times, add it to the mixed solution of acetone and petroleum ether with a volume ratio of 5:1, heat it to reflux and extract for 40 minutes, take it out and soften the surface of the ramie section with clean water Rinse the skin; add water to the enzymatic hydrolysis tank, then add concentrated sulfuric acid and hydrogen peroxide (concentration is 24%), finally add ramie degumming enzyme and catalase, stir at room temperature for 1 hour, add the above-mentioned ramie to soak, during every 1 hour Stir for 10 minutes, take it out when the ramie in the enzymolysis tank is completely dispersed into cotton-like fibers, and rub it repeatedly while rinsing until no yellow solution is squeezed out, then dry to obtain ramie fibers; Soak in KH550 aqueous solution for 30min...

Embodiment 2

[0036] A kind of method utilizing ramie fiber and river silt to prepare insulation brick, comprises the following steps:

[0037]After drying, cut the ramie to 20 mm and soak in water for 60 minutes, knock the ramie 6-7 times, add it to the mixed solution of acetone and petroleum ether with a volume ratio of 5:1, heat to reflux and extract for 50 minutes, take it out and soften the surface of the ramie section with clean water Rinse the skin; add water to the enzymatic hydrolysis tank, then add concentrated sulfuric acid and hydrogen peroxide (concentration is 25%), finally add ramie degumming enzyme and catalase, stir at room temperature for 1 hour, add the above-mentioned ramie to soak, during every 1 hour Stir for 10 minutes, take it out when the ramie in the enzymolysis tank is completely dispersed into cotton-like fibers, and rub it repeatedly while rinsing until no yellow solution is squeezed out, then dry to obtain ramie fibers; Soak in KH550 aqueous solution for 30 min...

Embodiment 3

[0039] A kind of method utilizing ramie fiber and river silt to prepare insulation brick, comprises the following steps:

[0040] Dry the ramie and cut it to 20 mm, soak it in water for 40 minutes, knock the ramie 6-7 times, add it to the mixed solution of acetone and petroleum ether with a volume ratio of 5:1, heat to reflux and extract for 20 minutes, take it out and soften the surface of the ramie section with clean water Rinse the skin; add water to the enzymolysis tank, then add concentrated sulfuric acid and hydrogen peroxide (concentration is 20%), finally add ramie degumming enzyme and catalase, stir at room temperature for 1 hour, then add the above-mentioned ramie to soak, during every 1 hour Stir for 10 minutes, take it out when the ramie in the enzymolysis tank is completely dispersed into cotton-like fibers, and rub it repeatedly while rinsing until no yellow solution is squeezed out, then dry to obtain ramie fibers; Soak in KH550 aqueous solution for 30 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com