Coarse TiCl4 filtering method

A filter method and filter element technology, applied in the direction of titanium halide, etc., can solve the problems of high production cost of cloth bag static pressure filter, hazards to operators and surrounding environment, and unguaranteed filter quality, so as to achieve excellent permeability and anti-corrosion Good washing effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

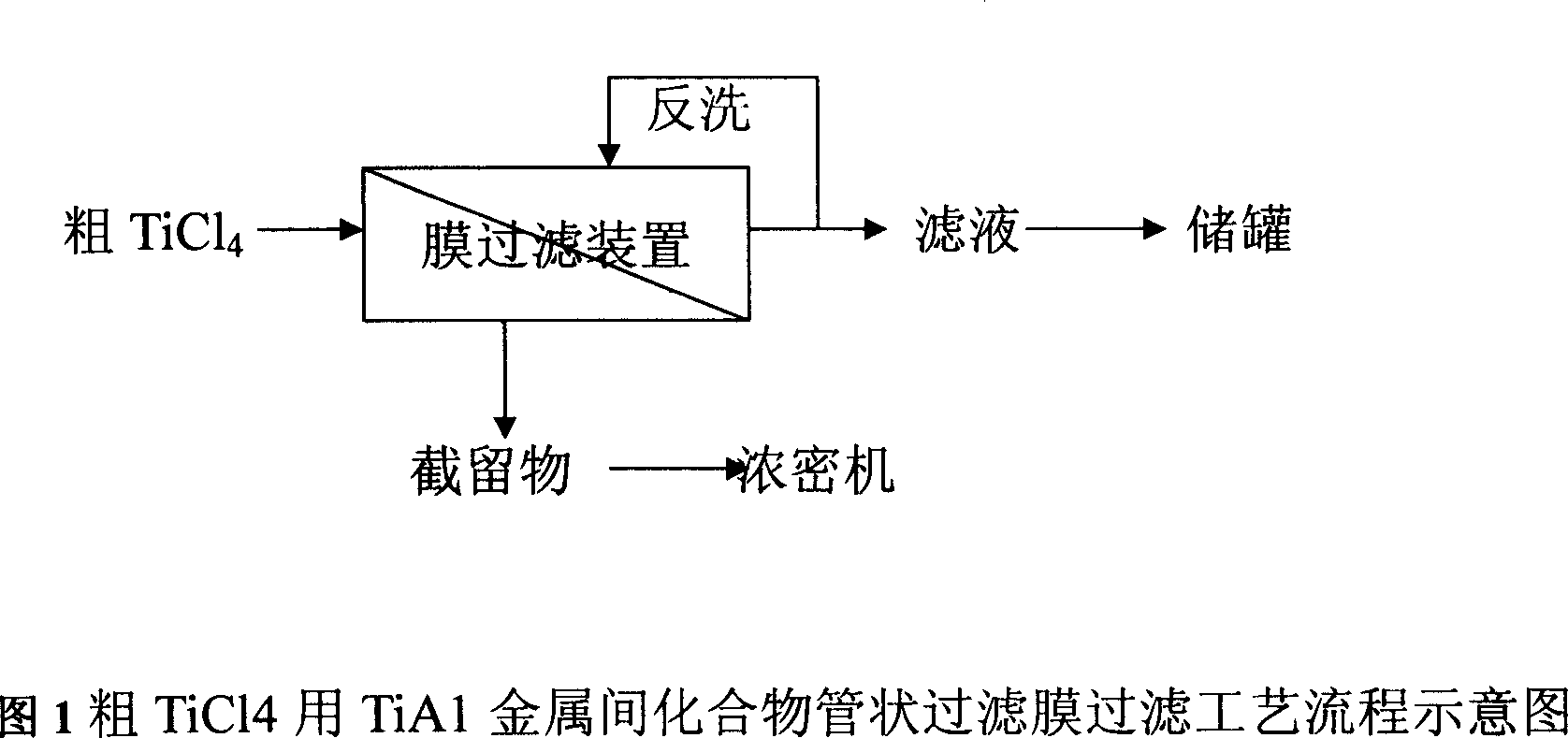

Image

Examples

Embodiment 1

[0021] Use TiAl intermetallic compound tubular filter membrane as the filter element, the membrane area is 0.02m 2 , the filtration pressure is 0.14Mpa, and the filtration is suspended after 30 minutes of filtration, using TiCl 4 The filtrate is used as backwashing agent, the backwashing pressure is 0.18MPa, the backwashing time is 5 seconds, and the filtration is resumed, and the continuous operation is 6 days, the volume ratio of filtrate / retentate is 9:1, and the filtration rate reaches 2.31m 3 m -2 h -1 , The solid content of the filtrate is less than 0.1%.

Embodiment 2

[0023] Use TiAl intermetallic compound tubular filter membrane as the filter element, the membrane area is 0.16m 2 , the filtration pressure is 0.17Mpa, the filtration time is 60 minutes, and the filtration is suspended. Dry air is used as the backwashing agent. The backwashing pressure is 0.21MPa. 8:1, filtration rate up to 2.18m 3 m -2 h -1 , The solid content of the filtrate is less than 0.1%.

Embodiment 3

[0025] Use TiAl intermetallic compound tubular filter membrane as the filter element, the membrane area is 0.34m 2 , the filtration pressure is 0.18Mpa, and the filtration is suspended after 90 minutes of filtration, using dry air and TiCl 4 The filtrate is used as backwashing agent, that is, gas-liquid mixed backwashing, the backwashing pressure is 0.21Mpa, and the filtration is resumed after backwashing for 30 seconds. It runs continuously for one month, the volume ratio of filtrate / retentate is 10:1, and the filtration rate reaches 2.46m 3 m -2 h -1 , The solid content of the filtrate is less than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com