Method and device thereof for treating cascade adsorbed water by radiating lateral and vertical flows

A technology of water treatment device and treatment method, which is applied in the direction of adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Problems such as uneven distribution of pollution amount and affecting effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

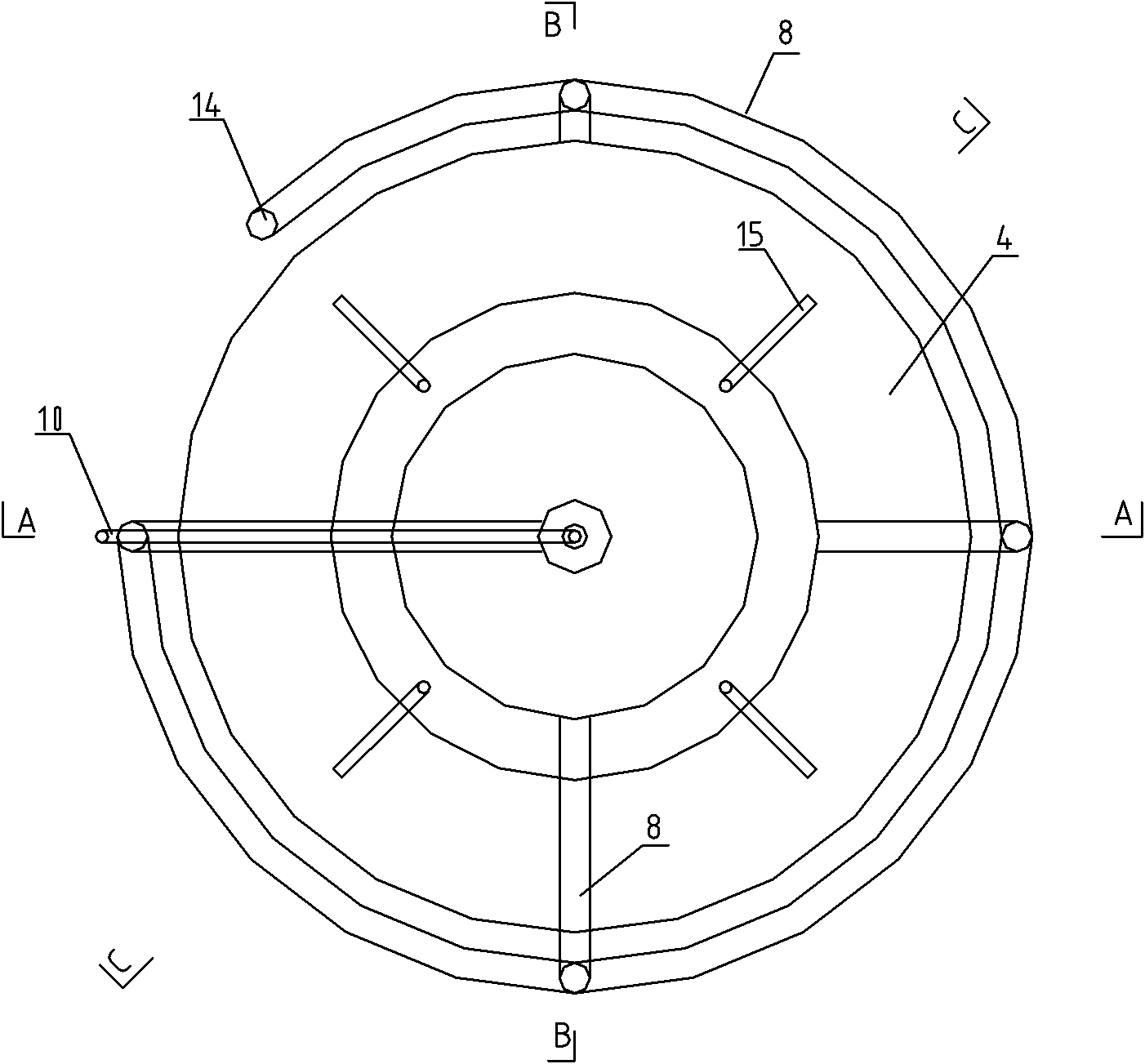

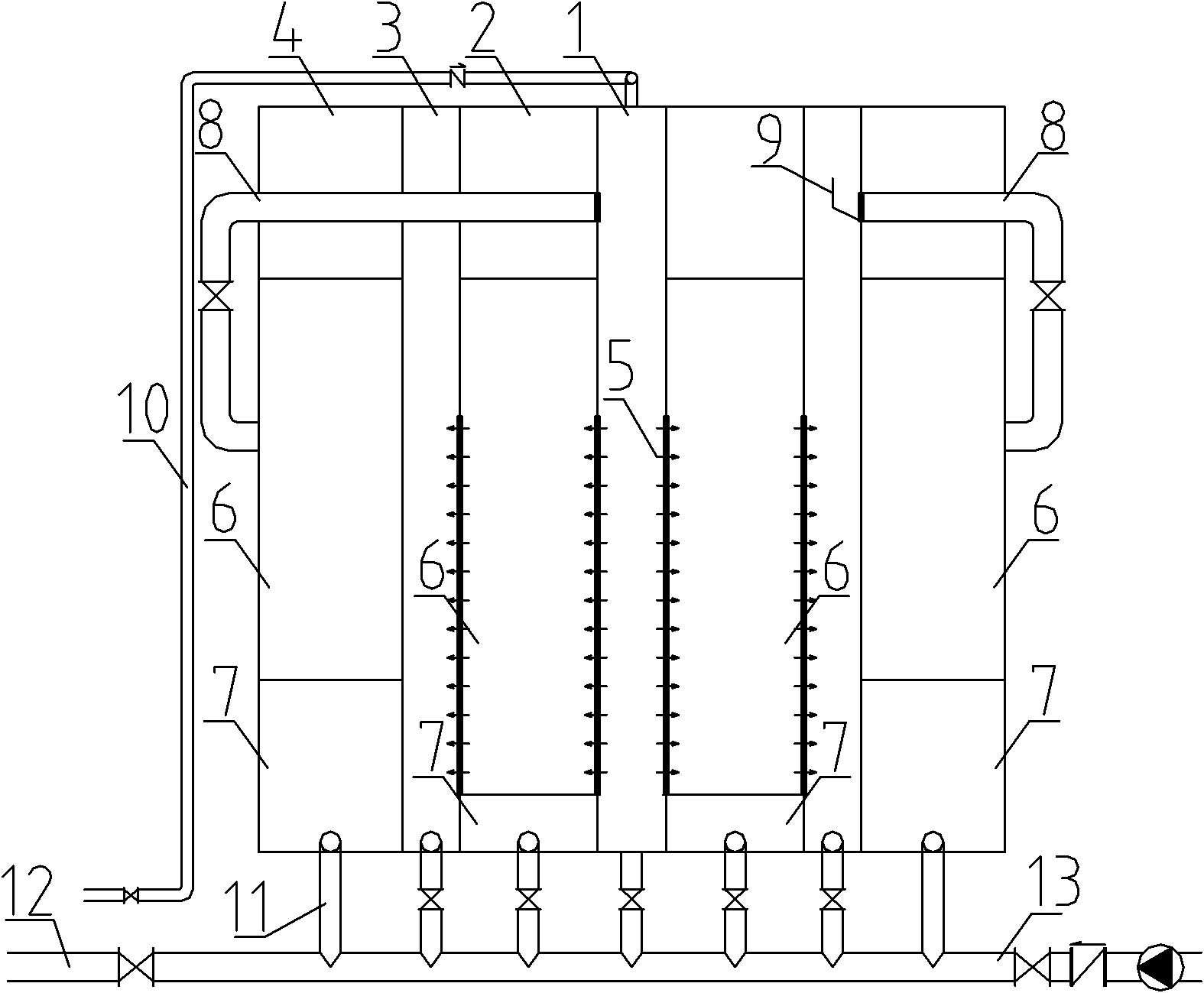

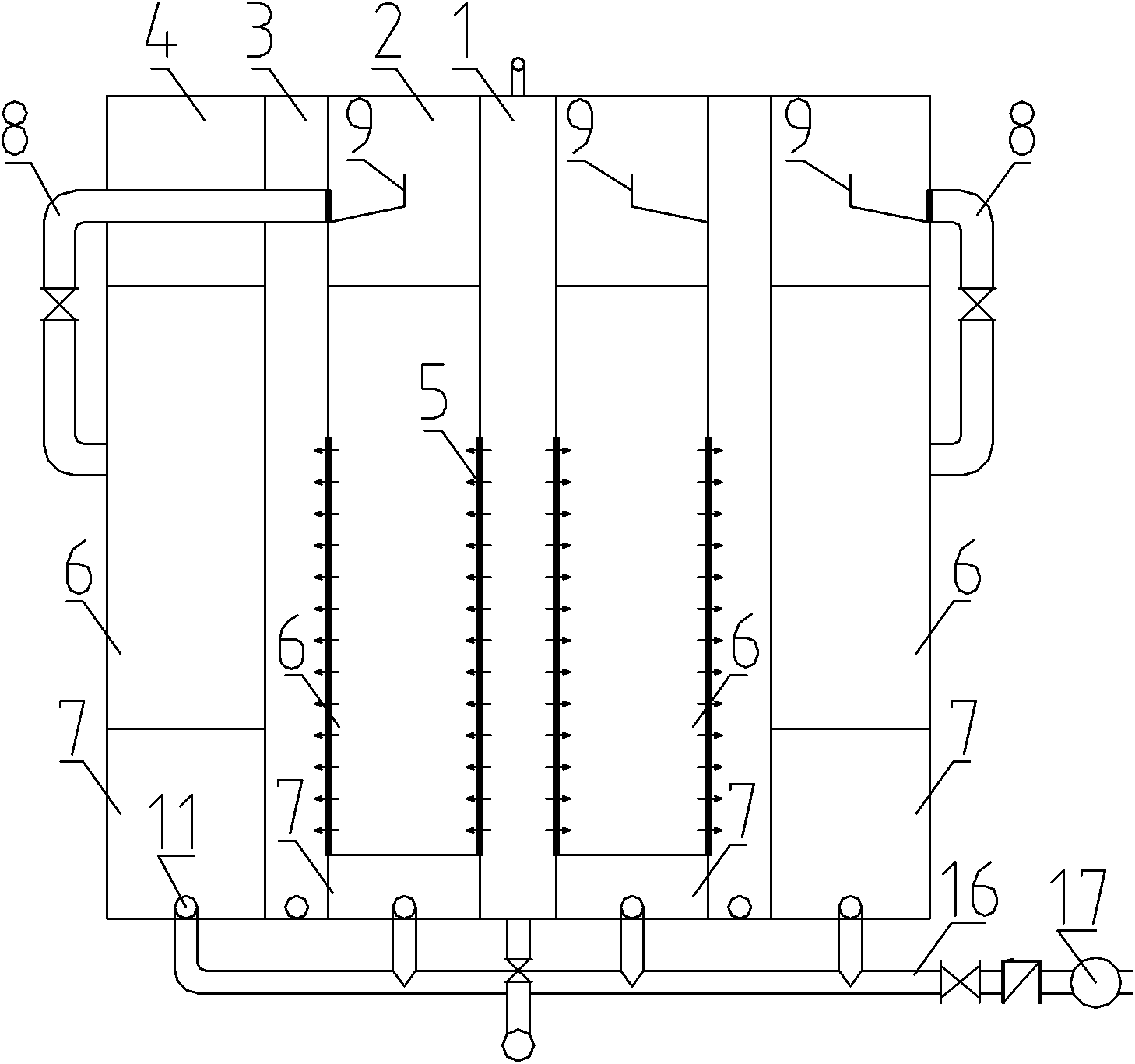

Embodiment 1

[0026] The raw water is lifted to the water inlet chamber of the radiation type side flow plus vertical flow cascade adsorption water treatment device through the lift pump, and the airtight pressure adsorption filter is used. The first stage adopts the side flow water inlet method, and the second stage adopts Pressure flow from top to bottom vertical water inlet mode, wherein: the filtration rate of the first-stage radial side flow filter chamber 2 decreases along the radius direction, the filtration rate of the inlet water is 1.12 m / h, and the filtration rate of the outlet water is 0.22 m / h h, the filtration rate of the second stage vertical flow filter chamber 4 is 0.46 m / h. The filter materials in the device are made of red mud-based environmental restoration materials. The particle size of the filter material in the first-stage radial lateral flow filter chamber is 1.25-1.6mm, and the laying thickness is 900mm; the particle size of the filter material in the second-stage ...

Embodiment 2

[0028] The raw water is lifted to the water inlet chamber of the radiation type side flow plus vertical flow cascade adsorption water treatment device through the lift pump, and the airtight pressure adsorption filter is used. The first stage adopts the side flow water inlet method, and the second stage adopts Pressure flow from top to bottom vertical water inlet mode, in which: the filtration rate of the first-stage radial side flow filter chamber 2 decreases along the radial direction, the influent filtration rate is 1.52 m / h, and the effluent filtration rate is 0.42 m / h h, the filtration rate of the second stage vertical flow filter chamber 4 is 0.30 m / h. The filter materials in the device are made of red mud-based environmental restoration materials. The particle size of the filter material in the first-stage radial lateral flow filter chamber is 1.6-2.0mm, and the laying thickness is 800mm; the particle size of the filter material in the second-stage vertical flow filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com