Apparatus and method for processing substrate

A processing device and processing method technology, applied in chemical instruments and methods, cleaning methods using liquids, spraying devices, etc., can solve the problems of poor reactivity, inability to uniformly process substrates, different problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

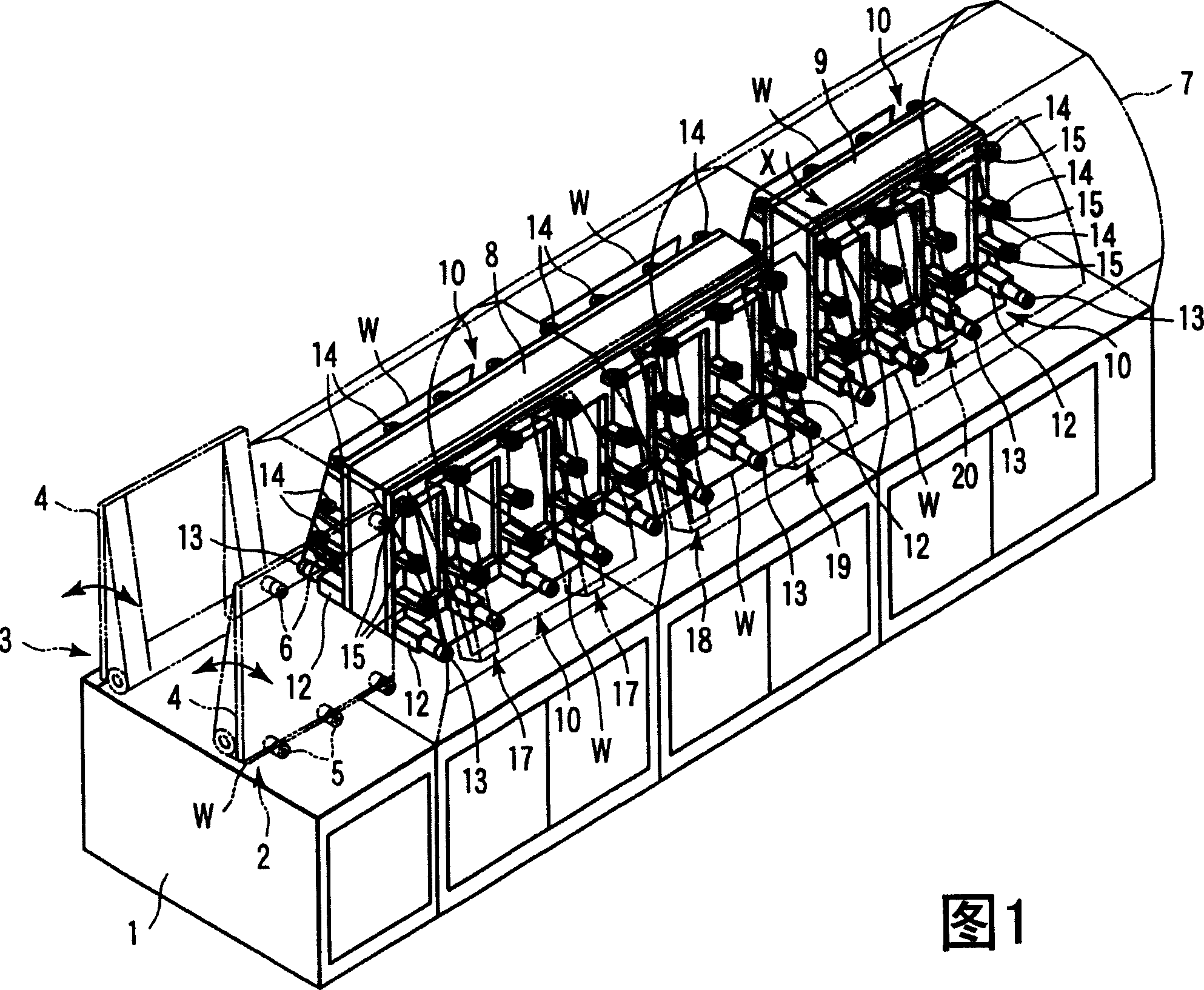

[0052] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

[0053] Figure 1 to Figure 8 The first embodiment of the present invention is shown. The treatment device shown in FIG. 1 has a base station 1 . At one longitudinal end of the upper surface of the base 1, a loading section 2 and an unloading section 3 are arranged laterally apart. The loading part 2 and the unloading part 3 have a rectangular plate-shaped supporting member 4, which can be driven to swing along the lateral direction of the base 1 indicated by the arrow, using the lower end as a fulcrum.

[0054]At the lower end of one side of the loading part 2 and the unloading part 3 (only the loading part 2 is shown in the figure), a plurality of lower supporting rollers 5 are arranged at regular intervals, and a plurality of upper supporting rollers are arranged at prescribed intervals at the upper end. 6. The lower backup roller 5 is rotationally driven by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com