Modified microfibrillated cellulose and resin composite material comprising the same

一种纤维素、树脂组合物的技术,应用在改性微纤化纤维素及含有其的树脂组合物及树脂复合材料领域,能够解决亲水性性质残留、凝聚·凝结、羟基残留等问题,达到防止凝聚、反应性优异、提高断裂韧性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

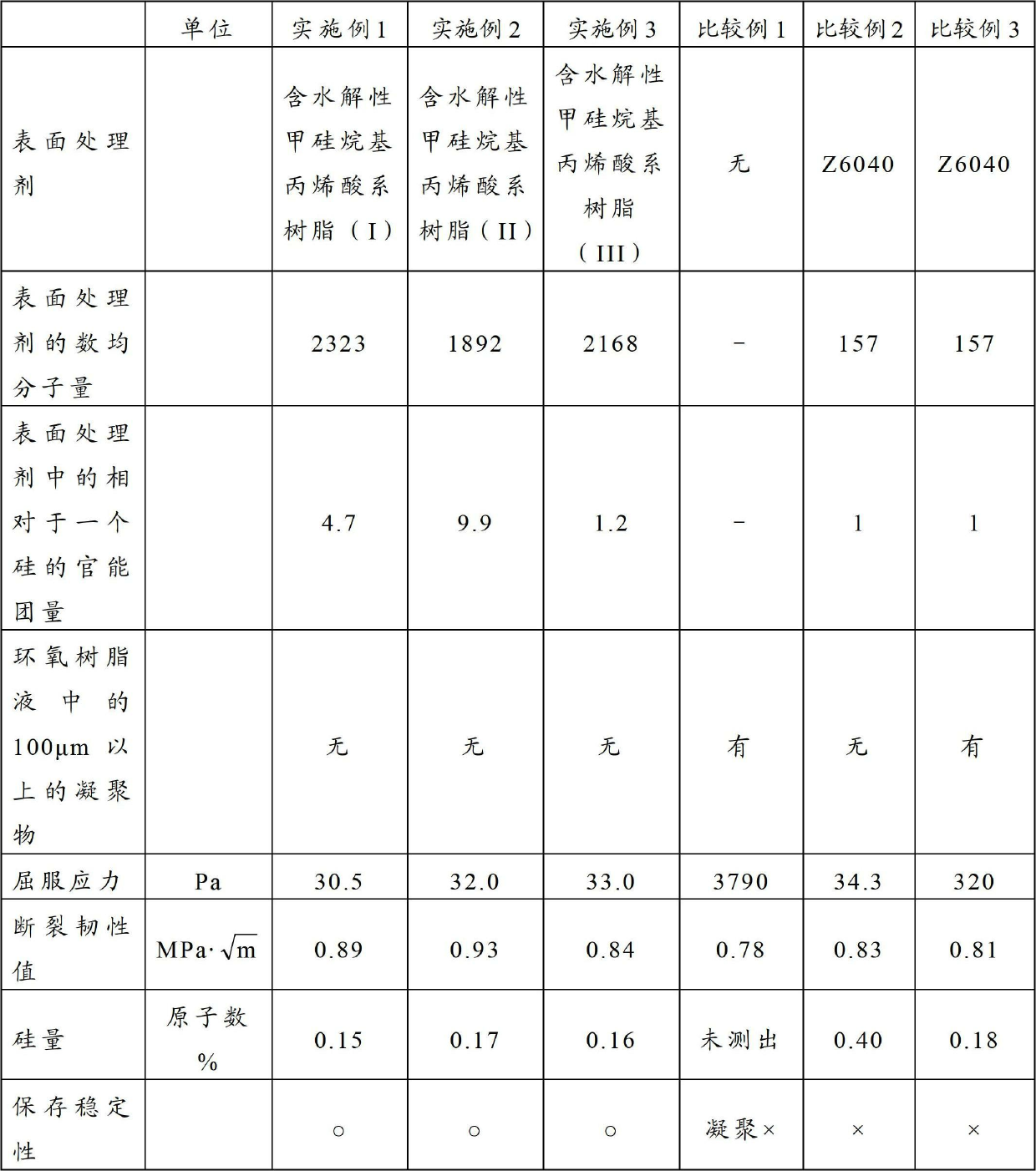

[0076] The present invention will be described in further detail below using examples. In addition, "part" and "%" in the text represent mass or weight basis.

Synthetic example 1

[0077] Synthesis Example 1

[0078] Weigh 468g of xylene and put it into a 3L stainless steel separable flask. It heated to 100 degreeC, stirring at 120 rpm under nitrogen flow. Next, 315 g of 2-ethylhexyl acrylate, 280 g of glycidyl methacrylate, and 105 g of SZ6030 (TORAY·DOWCORNING) were weighed into a 1L stainless steel container and stirred with a glass rod. Thereafter, 105 g of xylene and 84 g of Perbutyl O (NOF Corporation) were added and fully stirred and mixed with a glass rod. This mixed solution was transferred to a 1 L dropping funnel, and added dropwise to xylene heated to 100° C. over 4 hours. After the dropwise addition, the solution was kept at 100° C. for 7 hours to perform polymerization. The polymerized acrylic resin is referred to as a hydrolyzable silyl group-containing acrylic resin (I). Weigh 1 g of hydrolyzable silyl group-containing acrylic resin (I), add 5 g of toluene / methanol mixed solution (7 / 3 weight ratio) and stir, and place in a dryer at 1...

Embodiment 1

[0107] Add 1.9 g of 6% hydrochloric acid aqueous solution and 15 g of dimethylformamide to 33.3 g of hydrolyzable silyl acrylic resin (I), and stir with a stirrer for 1 hour to make the methoxy of hydrolyzable silyl acrylic resin (I) Silane hydrolysis. 20.6 g of dry microfibrillated cellulose and 132.8 g of xylene were added to this resin solution, and the mixture was stirred at 50 rpm for 6 hours with TK HIVISMIX f model (Tokuki Kagaku Kogyo) while heating to 80°C. Take 10 g of the modified microfibrillated cellulose resin mixture, add 80 g of xylene, and stir for 10 minutes with TK HOMODISPER of TK ROBOMIX at 3000 rpm. Thereafter, the solvent was removed by suction filtration, and the modified microfibrillated cellulose was washed. This washing operation was performed again with xylene, and thereafter, washing was performed twice by changing the washing solvent to ethanol. The resulting modified microfibrillated cellulose / ethanol slurry had a solids content of 22%. 8.6 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com