Gravel bed structure and in-situ purification system of riverway water formed thereby

A purification system and gravel bed technology, applied in the field of river water in-situ purification system, can solve the problems of increasing additional costs, changing the shape of the river, occupying a large area, etc., achieving convenient management and maintenance, saving labor costs, and easy automatic control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

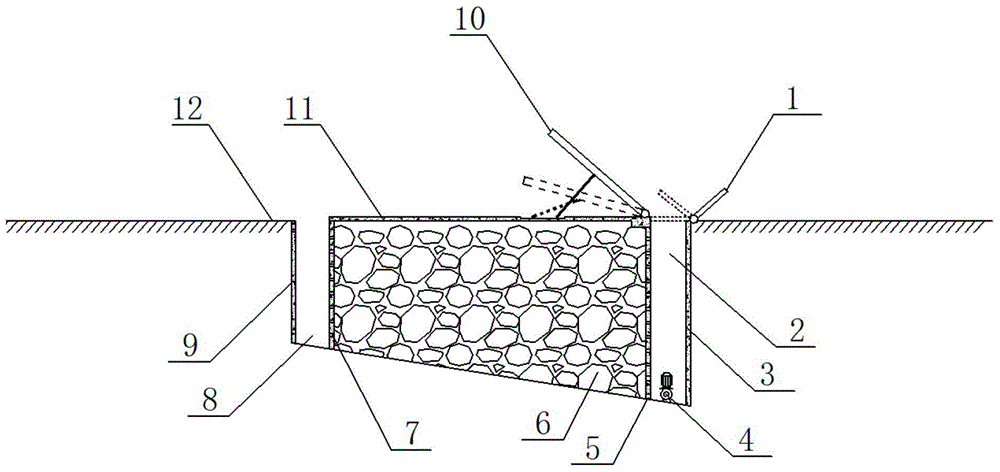

[0042] When the amount of water in the river is small, the flap dam 10 is raised, the river water is intercepted, the intake gate 1 is opened, and the low-pollution water of the river is introduced into the sedimentation area 2 below, and the sediment and suspended matter carried in the river water are initially settled and removed in the sedimentation area. , and then the river water passes through the first perforated concrete wall 5 and enters the gravel contact oxidation zone 6. The gravel contact oxidation zone is filled with gravels with a particle size of 50-150 mm. Organic matter and nitrogen and phosphorus nutrients in the low-pollution water of the river are removed. The treated low-pollution water flows out from the second perforated concrete wall 7 on the other side of the gravel reaction zone and enters the water outlet zone 8. Under the pressure of upstream water, the finally treated river water is discharged downstream. For this operating condition, see image ...

Embodiment 2

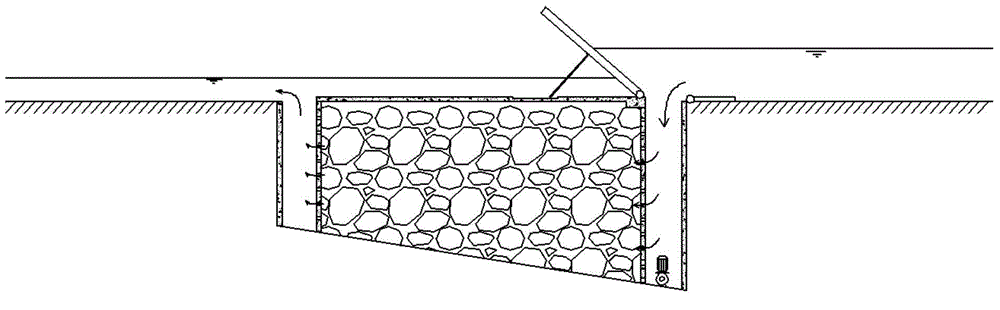

[0044] When the amount of water in the river is large, such as the flood season, the concentration of organic pollutants and nitrogen, phosphorus and nutrients in the river water is relatively low, and the water quality is relatively good. At this time, the flap dam 10 and the water inlet sluice 1 are all put to the level, and the upstream river water cannot enter the sedimentation zone 2 and the gravel contact oxidation zone 6, and directly flows to the downstream. For this operating condition, see Figure 4 .

Embodiment 3

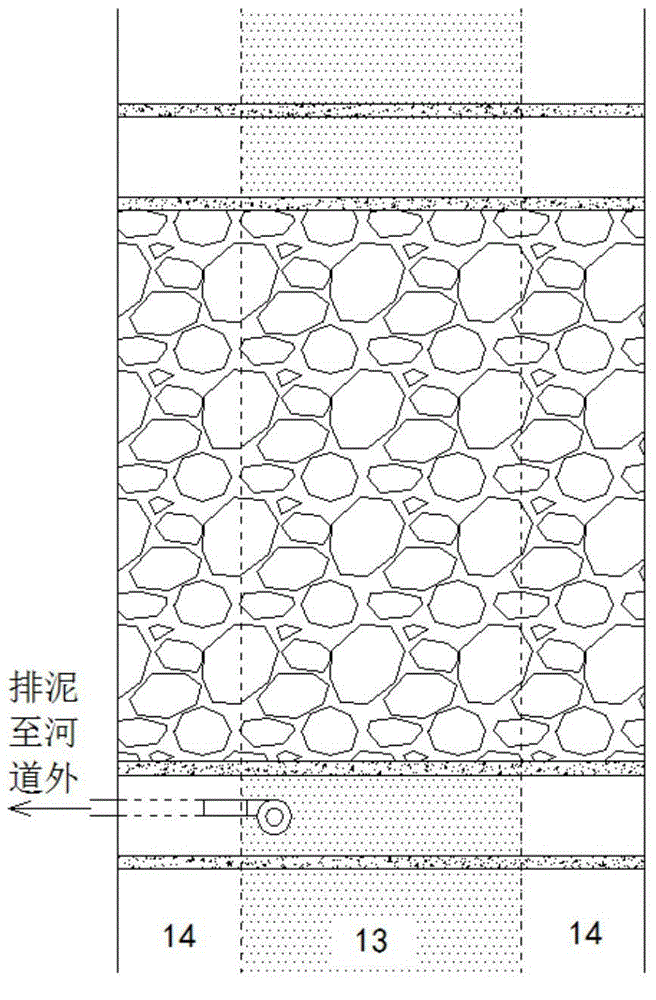

[0046] When the gravel bed runs for a period of time and needs to discharge mud, the flap dam 10 is fully opened and put to the level. At the same time, the water intake gate 1 is put to the level to prevent the channel water from being introduced into the sedimentation area 2 below. Open pump 4 afterwards, the pipeline of pump 4 passes river course slope protection 14 to river course 13 outer mud discharges (see specifically figure 2system floor plan). Since the sedimentation zone 2, the gravel contact oxidation zone 6, and the bottom slope of the water outlet zone 8 all have a terrain gradient of about 10%, when the sludge discharge pump is turned on, the downstream river water flows back into the gravel bed reaction zone for backwashing. The remaining sludge in the reaction zone enters the sedimentation zone with the suction of the sludge pump and the slope of the terrain, and then is discharged out of the river. For this operating condition, see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com