Overheating alarm wire clamp

A wire clip, overheating technology, applied in the direction of measuring heat, clamping/spring connection, instruments, etc., can solve the problems of high cost, increased management and construction links, and insufficient installation, so as to reduce construction costs and save operation and maintenance costs. , The effect of saving equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

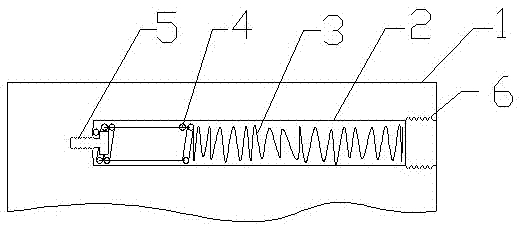

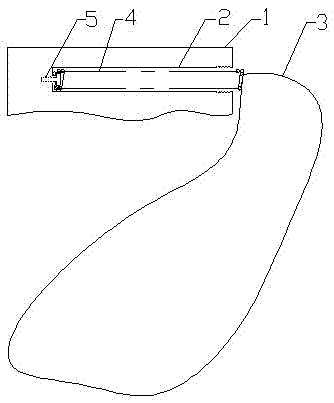

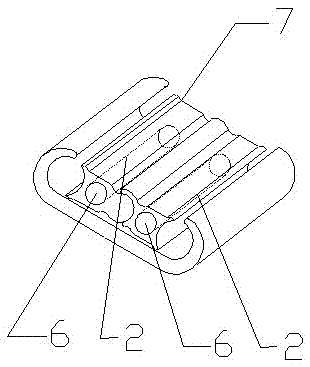

[0026] Such as figure 1 As shown, at least one cylindrical hole 2 is built in the clamp conductor member 1 of this embodiment, and a spring 4 and a warning cloth 3 pierced through the end of the spring 4 are compressed and loaded successively. The spring 4 is fixed on the cylindrical hole 2 by bolts 5 The bottom and the opening of the hole 2 are sealed with a low-melting alloy cover 6, and the low-melting alloy cover 6 is threaded and installed at the opening of the cylindrical hole 2, or further heated until the low-melting alloy cover 6 and the cylindrical hole 2 are welded and installed , to ensure a firm and airtight installation. Talcum powder is coated on the surface of the cylindrical hole 2 to reduce the friction force when the warning cloth 3 pops up. Warning cloth 3 selects insulation, frivolous cloth or macromolecule film material for use, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com