Printing and dyeing wastewater deep treatment system and printing and dyeing wastewater deep treatment method

A technology for advanced treatment, printing and dyeing wastewater, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc. Sewage treatment effect, improvement of treatment effect, effect of improvement of treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

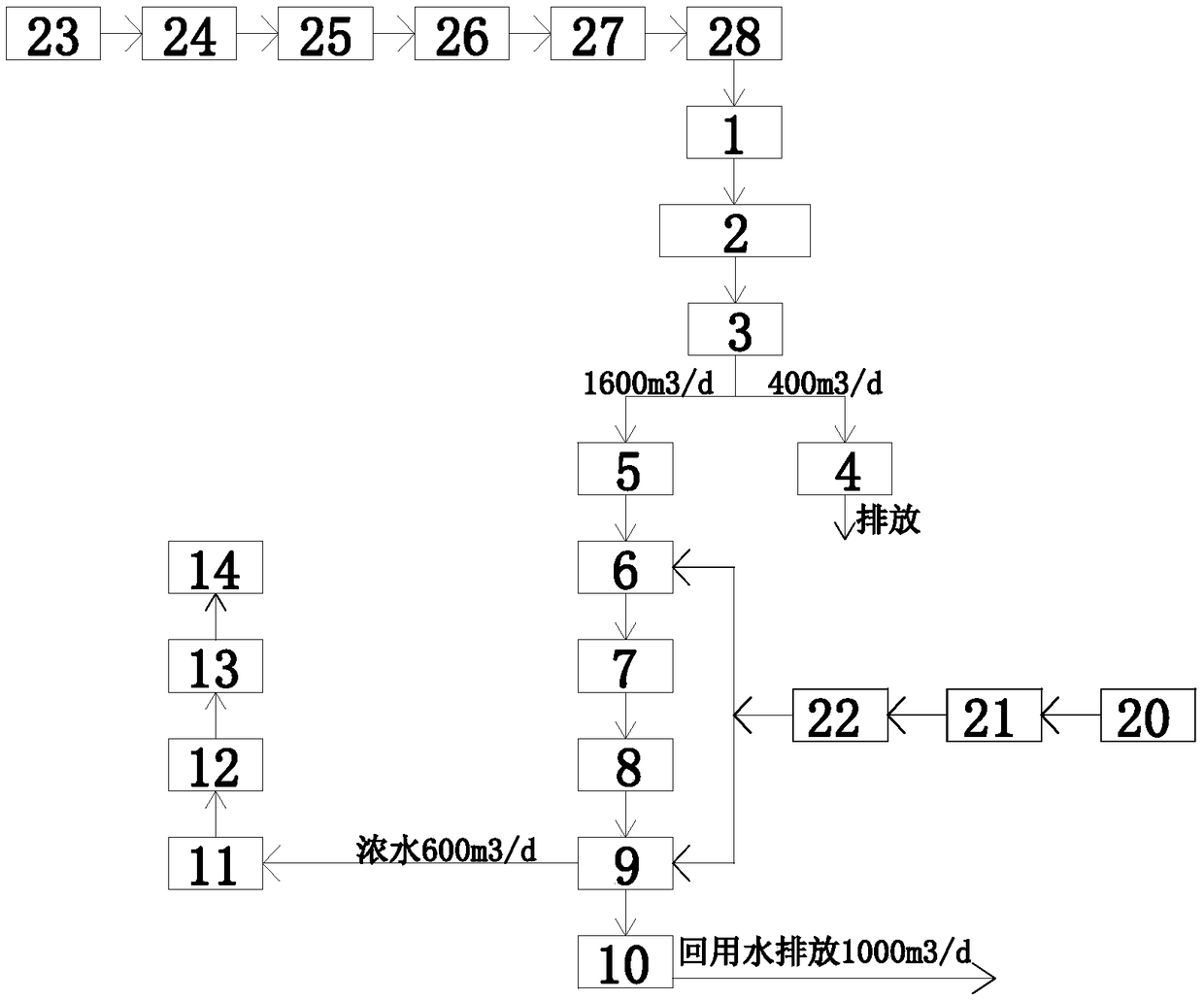

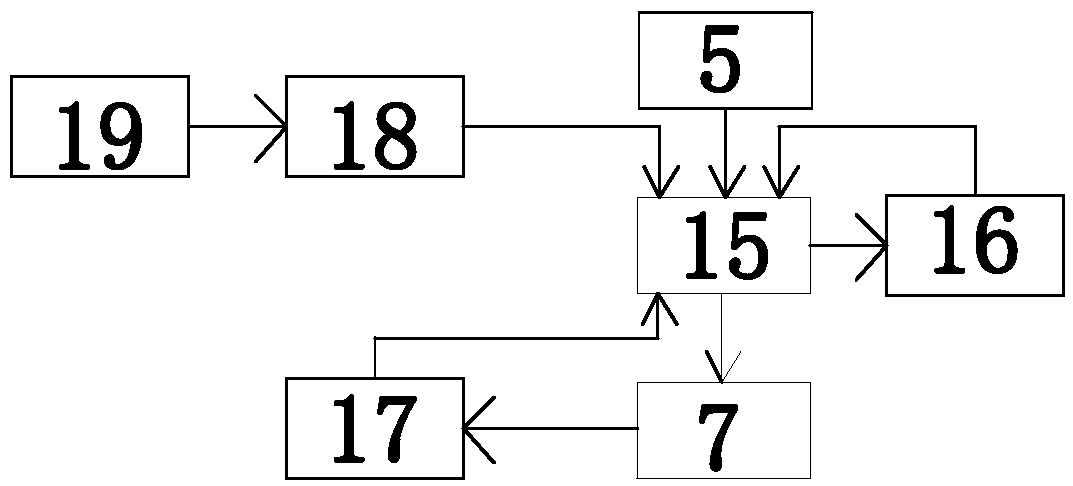

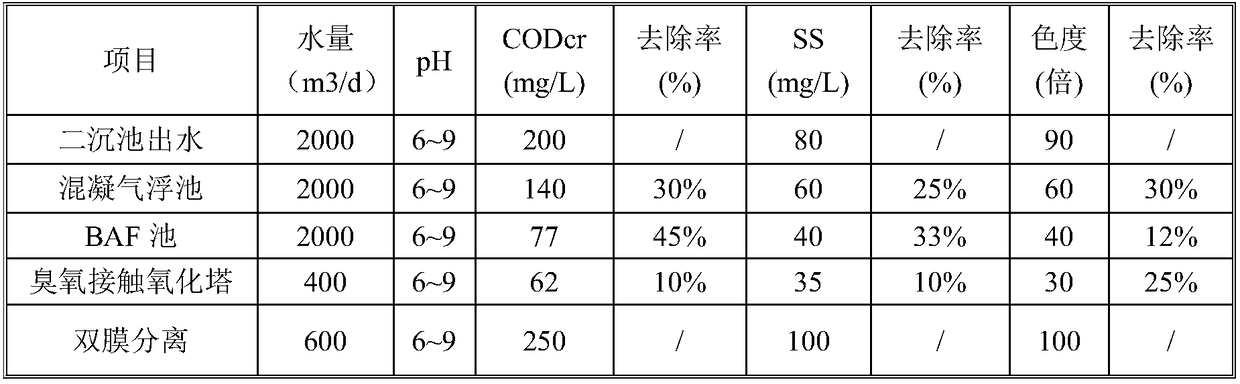

[0018] Example. A printing and dyeing wastewater advanced treatment system, composed of Figure 1 to Figure 2 As shown, it includes a pre-treatment unit, an advanced treatment unit and a reuse treatment unit connected through pipelines; the advanced treatment unit includes a coagulation air flotation tank 1, a biological aerated filter tank 2, a clear water tank 3 and an ozone tank connected in sequence through pipelines. Contact the oxidation tower 4; the reuse treatment unit includes a quartz sand filter 5 connected to the clean water tank 3 through a pipeline, and the quartz sand filter 5 is connected with an ultrafiltration membrane module 6, an ultrafiltration water production tank 7, and a security filter through a pipeline in sequence. Device 8 and reverse osmosis device 9, reverse osmosis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com