Dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment

A technology of solid-liquid separation and dynamic membrane, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high power consumption, achieve low investment cost, and improve filtration Water permeability, light pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

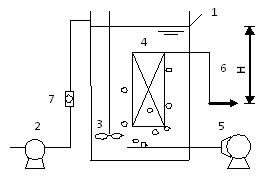

[0032] In this embodiment, the dynamic membrane reaction device for urban sewage treatment adds powdered sintered diatomaceous earth to improve the characteristics of the mixed solution and as a microbial carrier. The concentration of MLSS in the mixed solution is 10000 mg / L, and the gravity self-flow is carried out under the liquid level pressure difference of 4 KPa. water. The specific implementation method is as follows:

[0033] 1. Use 200-mesh stainless steel mesh as the support structure of the dynamic membrane module 4. The support structure is tubular, and the tubular dynamic membrane module 4 is fixed and immersed in the dynamic membrane bioreactor 1.

[0034] 2. When the dynamic membrane is pre-coated, the time relay 7 starts to control the water inlet pump 2 not to enter the water, the support body starts to discharge water under the action of the vacuum pump, and the pre-coated water flows back into the dynamic membrane bioreactor 1. After that, the time relay ...

Embodiment 2

[0038] In this embodiment, the dynamic membrane reaction device for urban sewage treatment adds powdered sintered diatomaceous earth to improve the characteristics of the mixed solution and serve as a microbial carrier. The concentration of MLSS in the mixed solution is 10000 mg / L, and the gravity self-flow is carried out under the liquid level pressure difference of 2 KPa. water. The specific implementation method is as follows:

[0039] 1. Use 200-mesh stainless steel mesh as the support structure of the dynamic membrane module 4. The support structure adopts a tubular type, and the tubular dynamic membrane module is fixed and immersed in the reaction device.

[0040] 2. When the dynamic membrane is pre-coated, the time relay 7 starts to control the water inlet pump 2 not to enter the water, the support body starts to discharge water under the action of the vacuum pump, and the pre-coated water flows back into the dynamic membrane bioreactor 1. After that, the time relay...

Embodiment 3

[0044] In this embodiment, the dynamic membrane reaction device for urban sewage treatment is added with powdered activated carbon to improve the characteristics of the mixed liquid and serve as a microbial carrier. The concentration of MLSS in the mixed liquid is 12000 mg / L, and the gravity self-flowing water is carried out under the liquid level pressure difference of 4 KPa. The specific implementation method is as follows:

[0045] 1. Use 200-mesh stainless steel mesh as the dynamic membrane module 4, and the support body structure is tubular, and the tubular dynamic membrane module is fixed and immersed in the reaction device.

[0046] 2. During the pre-coating of the dynamic film, the time relay 7 starts to control the water inlet pump not to enter the water, and the support body starts to discharge water under the action of the vacuum pump, and the pre-coated water is returned to the reactor device by the vacuum pump. After that, the time relay controls the water infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com