Iron-carbon micro-electrolysis filler and preparation method thereof

A technology of iron-carbon micro-electrolysis and iron products, applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, water/sewage treatment, etc., can solve the problem of low reflection effect, high maintenance cost and large floor space and other problems, to achieve the effect of good specific surface area, control of production cost, and good porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

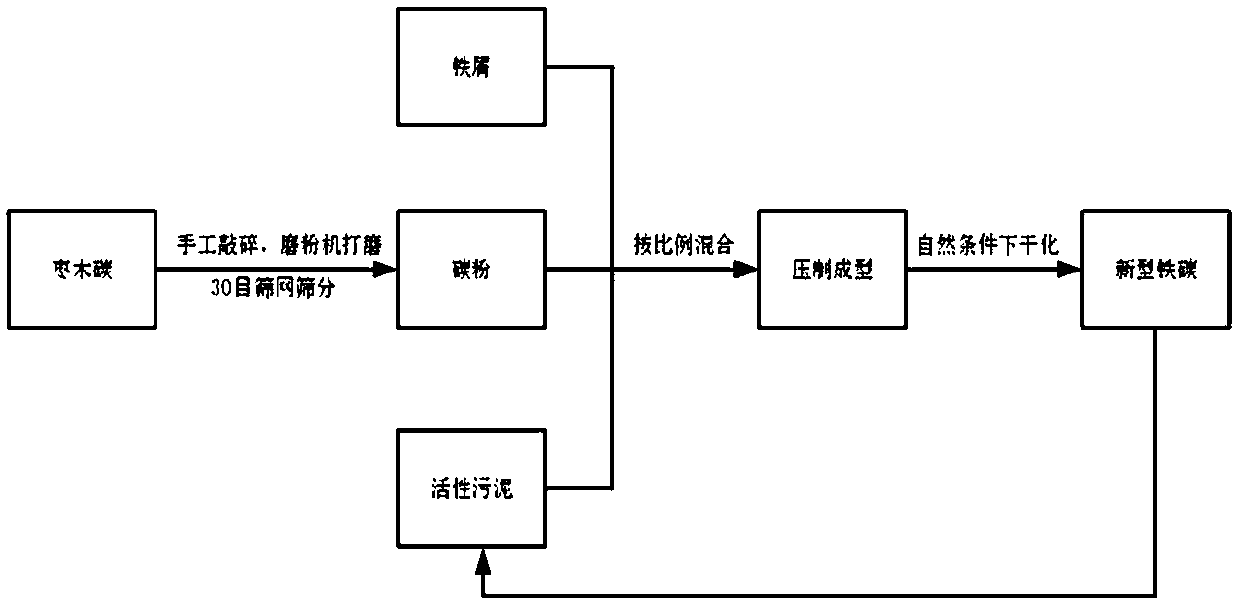

Method used

Image

Examples

Embodiment 1

[0039] Iron carbon is made by mixing iron filings (g): carbon powder (g): sludge (ml) = 1:1:0. Without adding activated sludge, it is directly mixed and compacted with carbon powder and iron powder. It can be shaped, and it can be completely dispersed after being gently pinched or put into wastewater.

Embodiment 2

[0041] Iron carbon is made by mixing iron filings (g): carbon powder (g): sludge (ml) = 3:3:6. Soak the prepared iron carbon in the prepared phosphorus-containing wastewater, place it in a shaker, simulate the hydraulic shock in the actual operation, shake continuously for two weeks under the conditions of 90r / min and 20°C, and the filler does not appear slightly broken. Condition.

Embodiment 3

[0043] Iron carbon is made by mixing iron filings (g): carbon powder (g): sludge (ml) = 3:3:9.9. Soak the prepared iron carbon in the prepared phosphorus-containing wastewater, place it in a shaker, simulate the hydraulic shock in the actual operation, shake continuously for two weeks under the conditions of 90r / min and 20°C, and the filler does not break.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com